Level bar base

A technology of level ruler and blister seat, applied in the field of level ruler base, which can solve problems such as easy to leave glue, high production cost, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

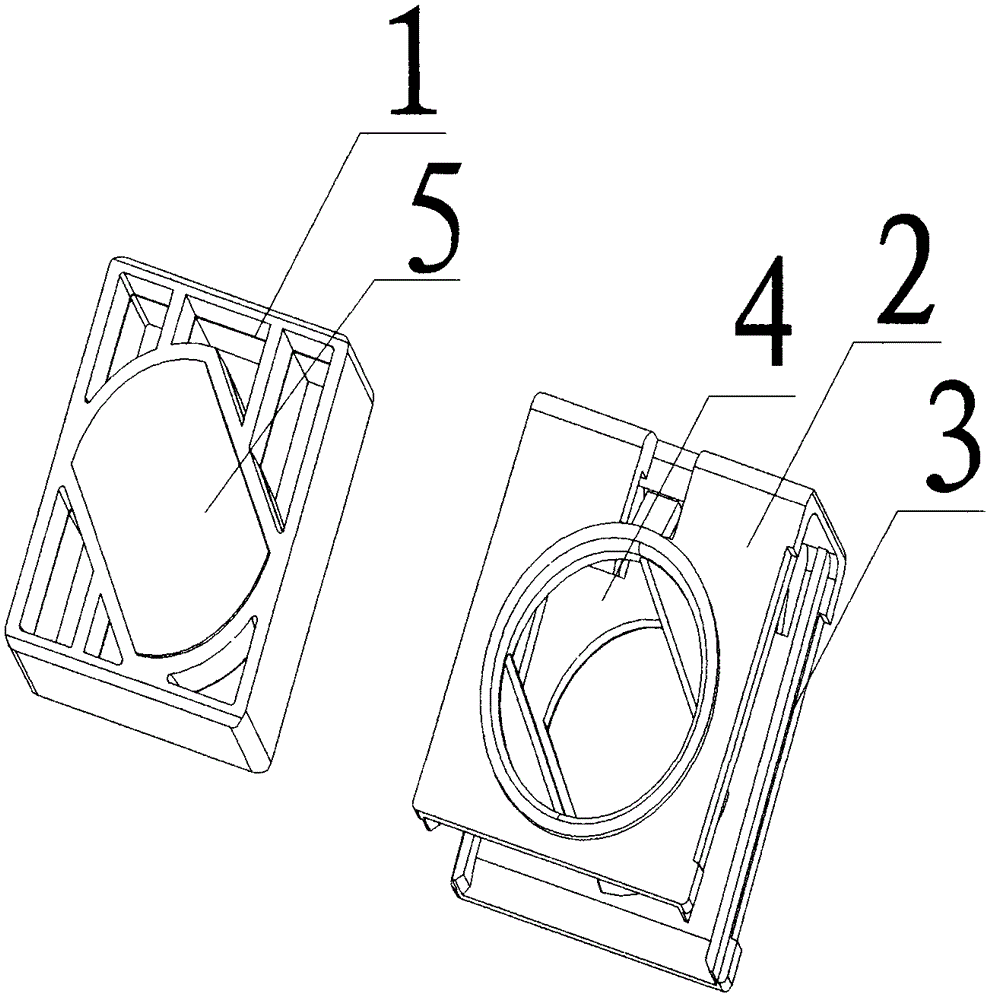

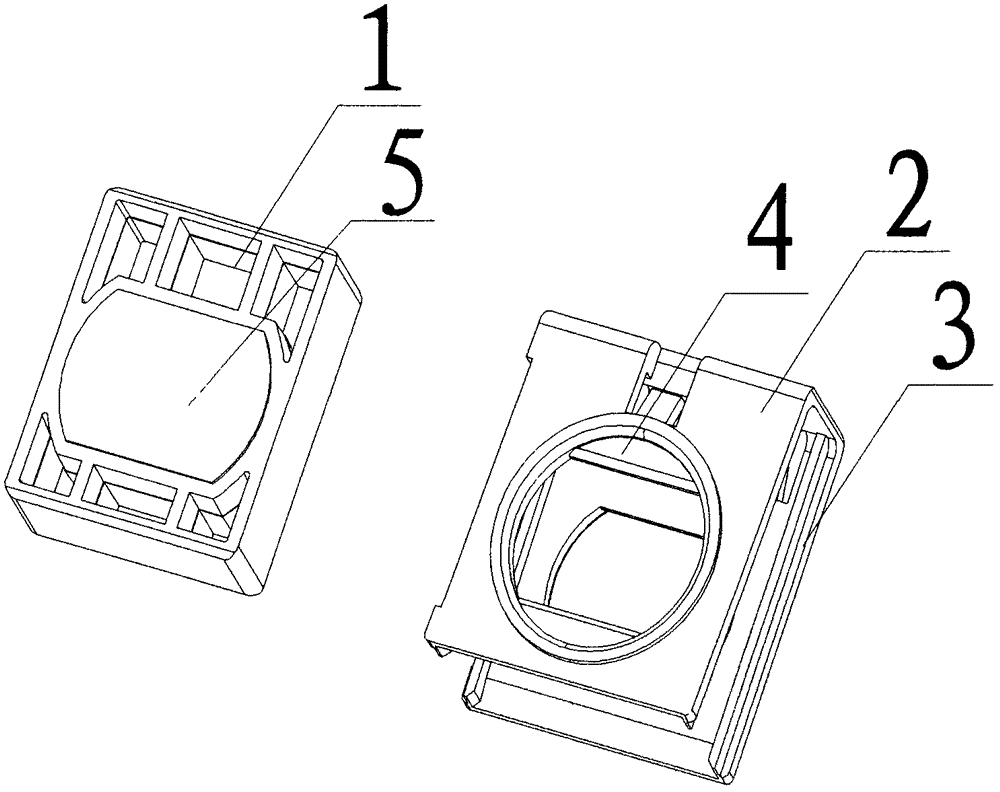

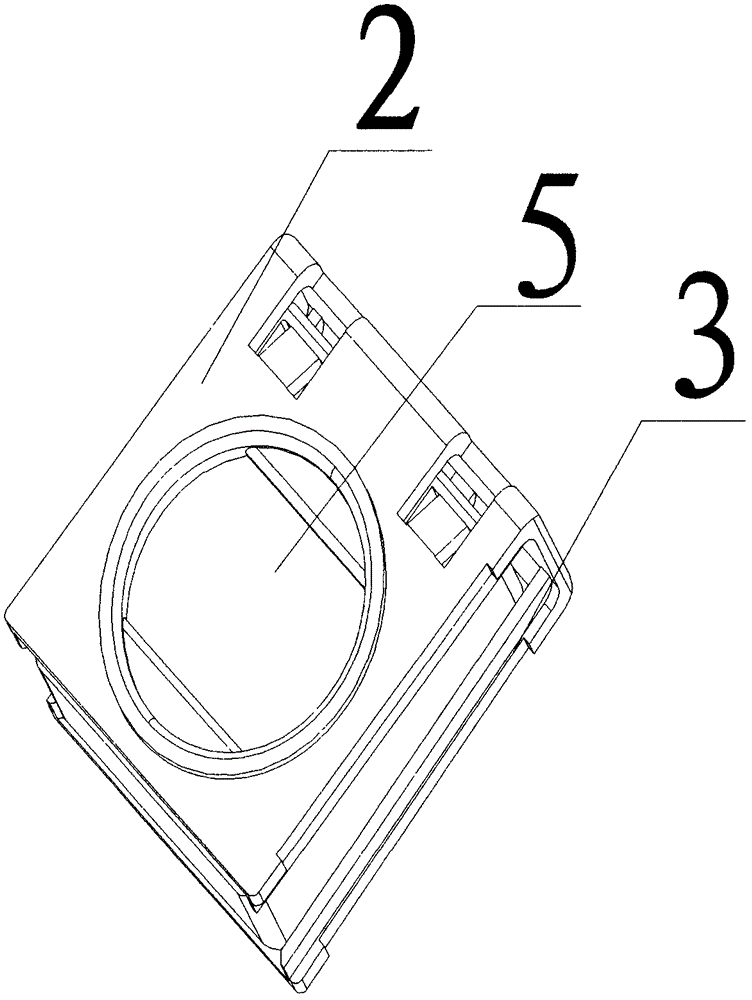

[0019] Such as figure 1 and figure 2 As shown, a level base of the present invention includes a body and a blister seat 11 installed in the body, the body includes a front cover 2 and a rear cover 3, and the front cover 2 and the rear cover 3 are provided with observation holes 4, The shape of the blister seat 1 matches the internal structure of the body, and a level ruler and a blister 5 are inlaid in the middle of the blister seat 1 . The body includes a front cover 2 and a rear cover 3 movably connected at one end, and the other end is fastened through a buckle. According to different spirit levels used, the blister seat 1 is rectangular, and the water bubble 5 and the bottom edge of the blister seat 1 of the level form an included angle of 90 degrees or a 45 degree angle

[0020] The observation holes 4 arranged on the front cover 2 and the rear cover 3 are circular, and may also be in the shape of water bubbles 5 for the level. One of observation hole 4 on front cover...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap