Apparatus for treating the surface of a curved material

A surface treatment and curved surface technology, applied in the direction of discharge tubes, electrical components, plasma, etc., can solve the problems that it is impossible to process the surface of the target object, large curved depressions, and it is difficult to uniformly process the surface of the curved object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

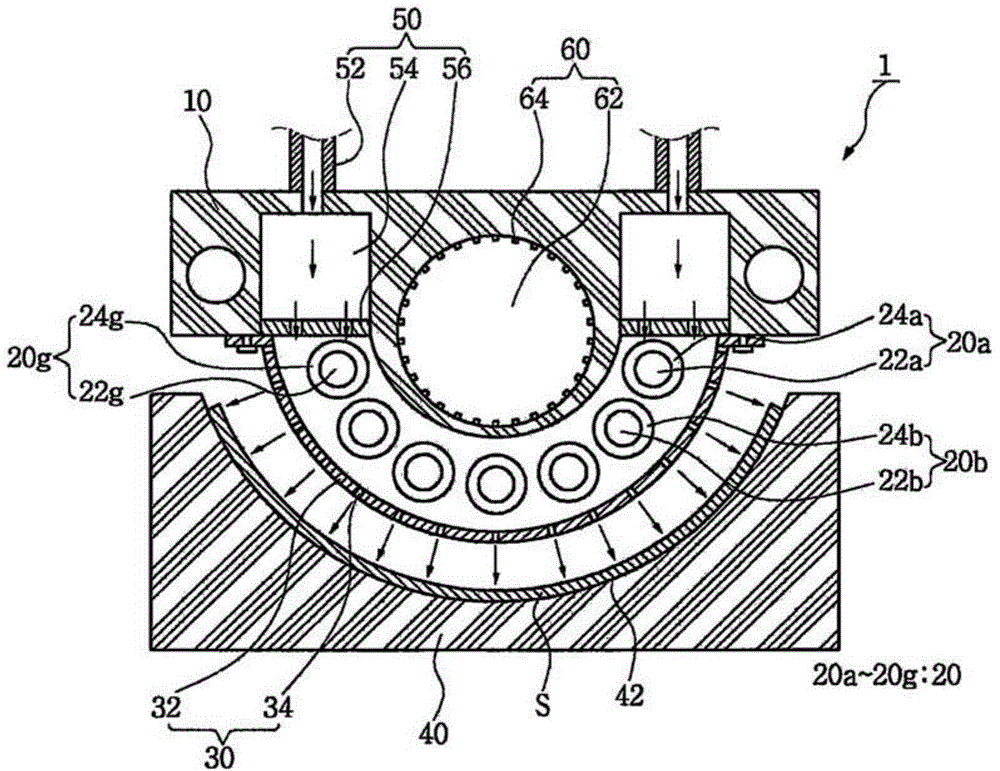

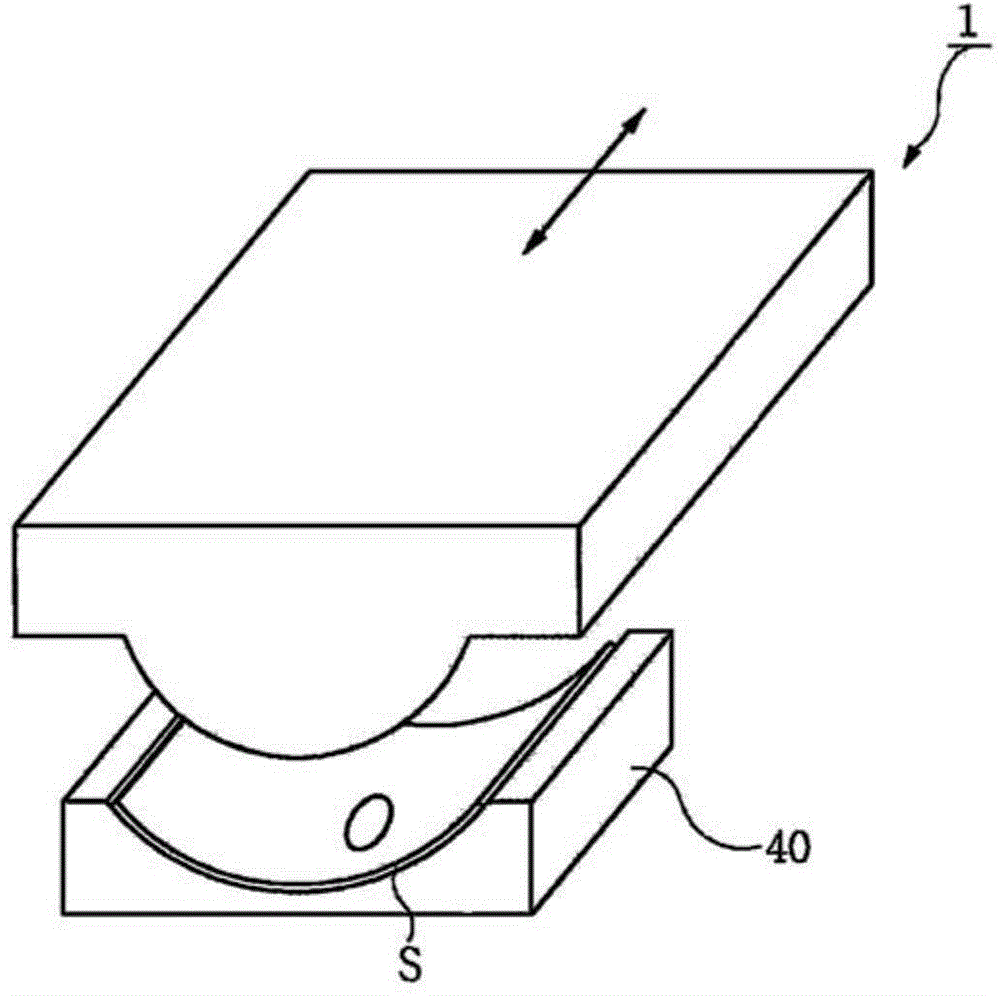

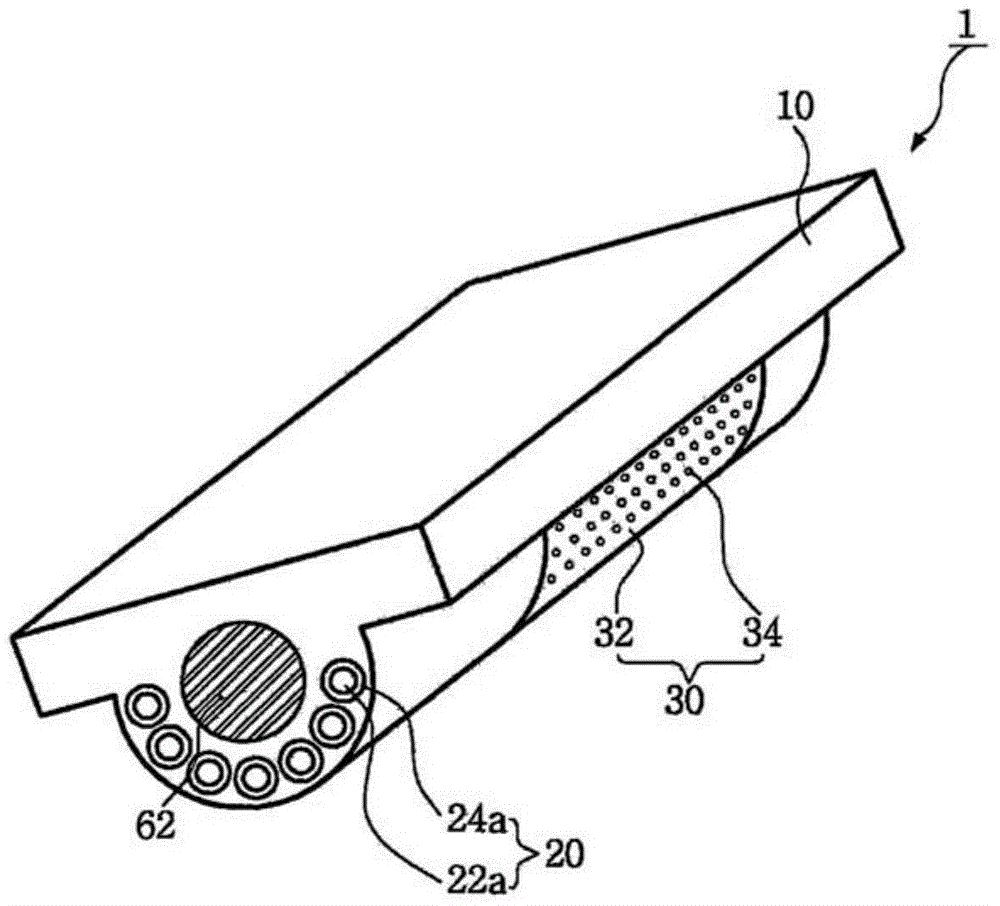

[0017] Such as figure 1 As shown, the surface treatment apparatus 1 for bending objects according to the embodiment of the present invention includes a high voltage electrode unit 20 , a housing 10 , a plasma emitting unit 30 , a reactive gas supply unit 50 and a cooling unit 60 .

[0018] Such as figure 1 As shown, the high voltage electrode unit 20 includes a plurality of rod-shaped high voltage electrodes 20a to 20g arranged along a downwardly convex curved surface having a curvature corresponding to that of a curved object S to be processed. That is, the high-voltage electrode unit 20 , which does not include a single high-voltage electrode, is configured in such a manner that a plurality of high-voltage electrodes are arranged at the same curvature as that of a curved object to be processed.

[0019] Preferably, each of the high-voltage ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap