Self-propelled wire winding machine for storing copper-clad aluminum wire

A copper-clad aluminum self-propelled technology, which is applied in the field of wire take-up machines, can solve problems such as tearing or separation, affecting the electrical performance of finished products, and reducing the pass rate of finished products, so as to improve the service life, good practical effect, and improve the quality of finished products and yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

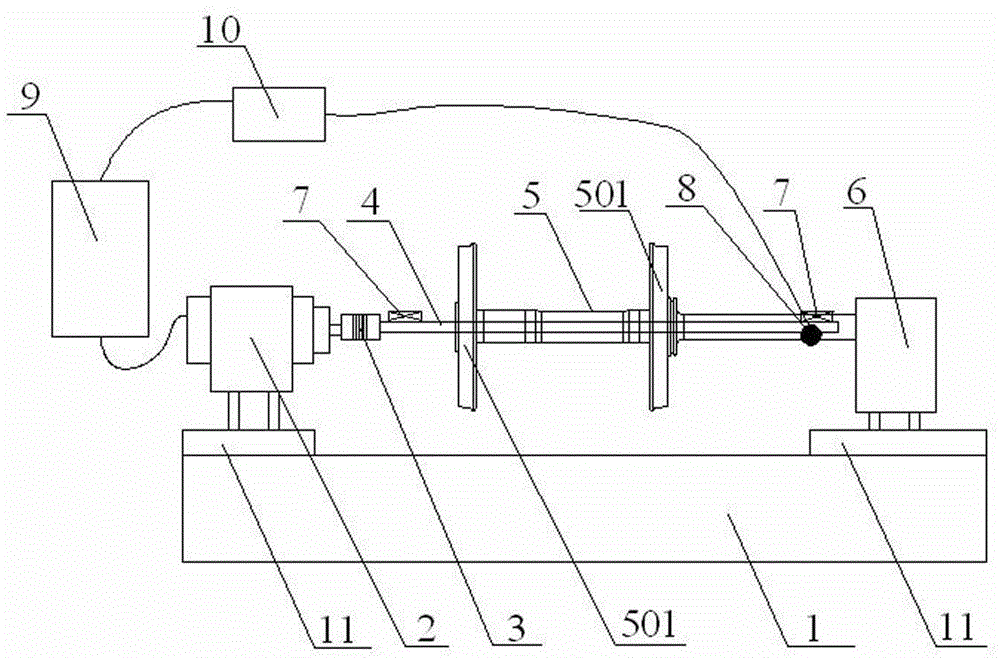

[0015] A self-propelled wire take-up machine for copper-clad aluminum wire storage, comprising a frame 1 and a drive motor 2 arranged on the frame 1, the output shaft of the drive motor 2 is driven by the reduction gear of the reducer 3 and the take-up shaft 4 connection, the take-up shaft 4 is set with an I-shaped wheel 5 for winding to the copper-clad aluminum wire, and the frame 1 is also provided with a traction device 6, and the traction device 6 is connected to the end of the I-shaped wheel 5 through its traction shaft. The disc 501 at the top is fixedly connected, the end of the traction shaft connected to the I-wheel 5 disc 501 is in the shape of a truncated cone, and the front end of the truncated cone is also provided with a gripping friction to prevent slipping between the traction shaft and the I-wheel 5 circle; said take-up shaft 4 is also provided with two travel switches 7, the distance between the two travel switches 7 is twice the length of the I-shaped wheel 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com