Scraping and compacting mechanism for floating coal and its application method

A floating coal and flat pressing technology, applied in the petroleum industry, coke ovens, charging devices, etc., can solve the problems of difficulty in flattening, poor compaction effect, poor adaptability to the undulation of coal cake floating coal, etc., to save materials. and cost, convenient installation, debugging and maintenance, and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

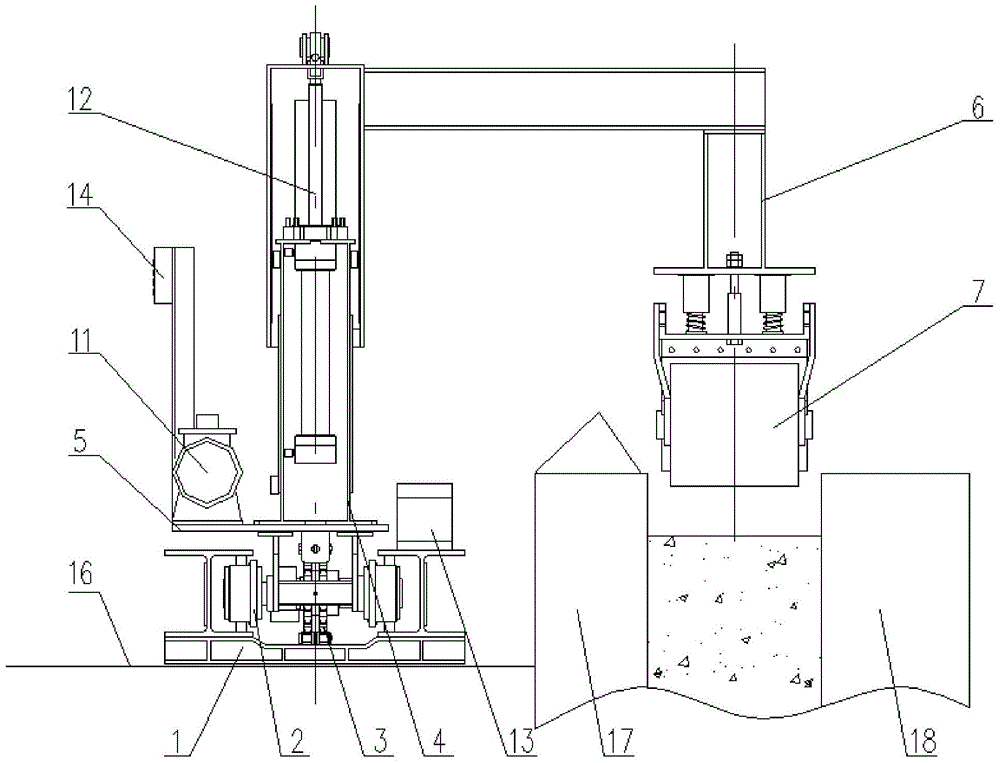

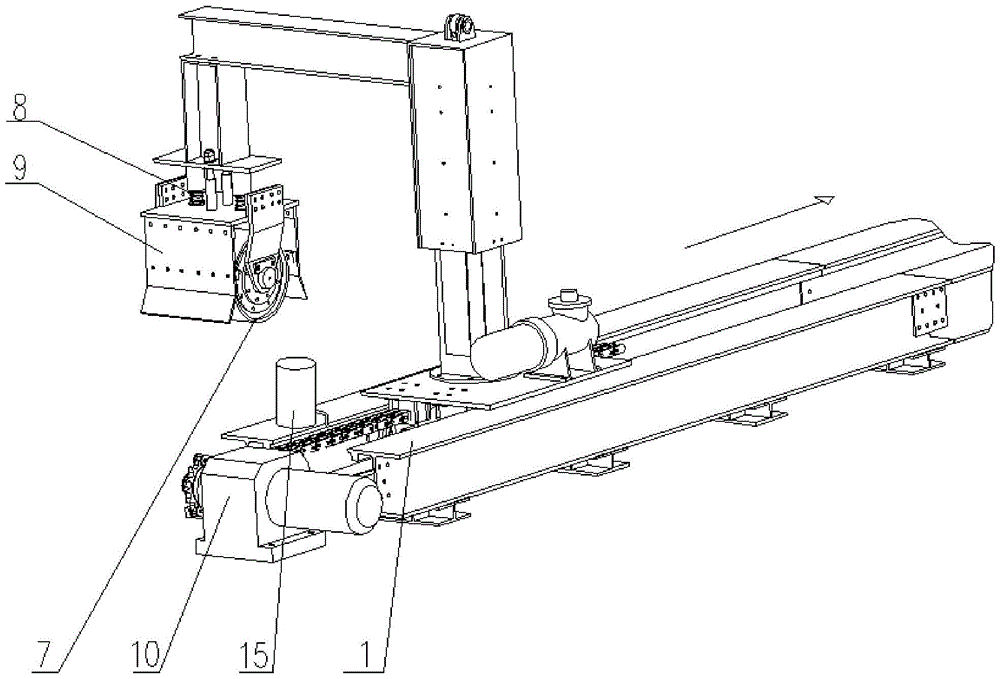

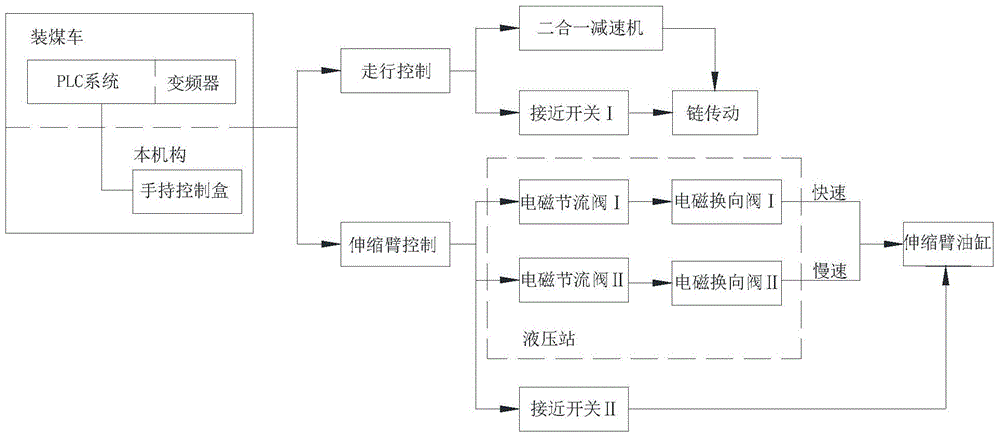

[0033] like Figure 1-Figure 3 As shown, a floating coal scraping and compacting mechanism includes a track device 1, the track device 1 is located on the top platform 16, and a chain transmission device 3 powered by a two-in-one reducer 10 is arranged inside the track device 1 , the chain transmission device 3 is connected with the running wheel pair 2 installed on the guide rail of the track device 1, the frame 5 is installed on the track device 1 through the running wheel pair 2, and the telescopic arm 4, the hydraulic station 11 and the telescopic arm 4 are installed on the frame 5 Hand-held control box 14, a hanger 6 is installed on the outside of the top of the telescopic arm 4, a compacting wheel 7 is installed on the bottom of the hanger 6, and scrapers 9 are installed on both sides of the compacting wheel 7, so that the compacting wheel 7 and the scraper 9 are in the same The dimension coordination between the coal wall 17 and the outer coal wall 18 is convenient for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com