Novel sealing strip and sealing method for preventing slurry leakage of novel sealing strip

A sealing strip, a new type of technology, applied to the preparation of building components on site, the connectors of formwork/formwork/work frame, construction, etc., can solve the problem of cement slurry overflow in joints, cannot solve the problem of cement slurry overflow, and affect aluminum alloys. Life and other issues to achieve the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

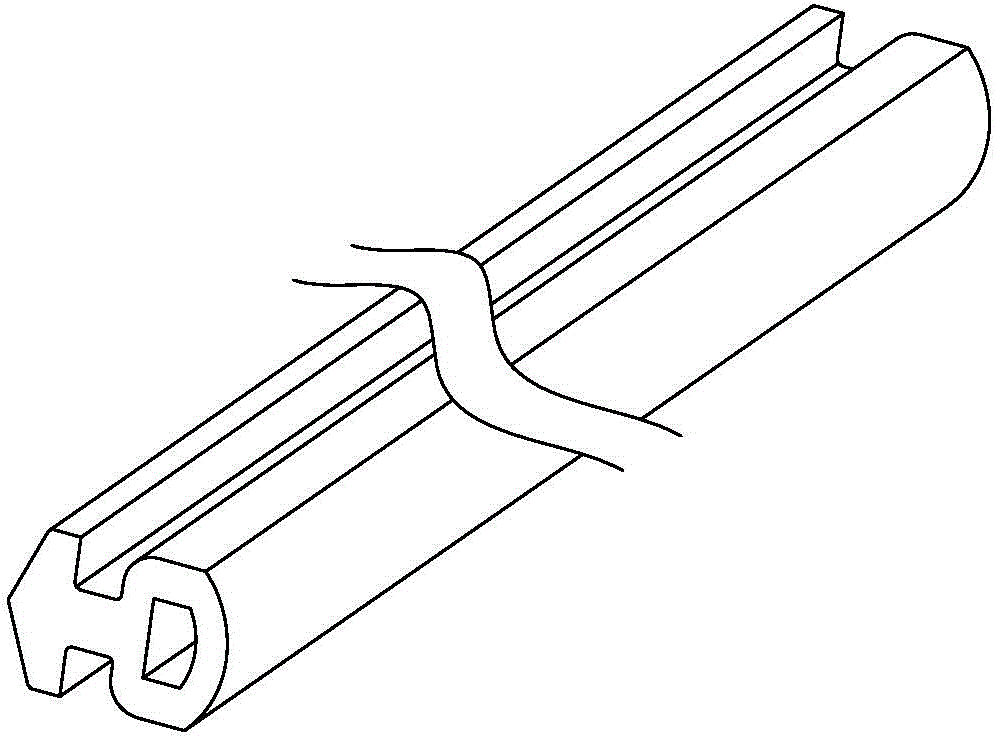

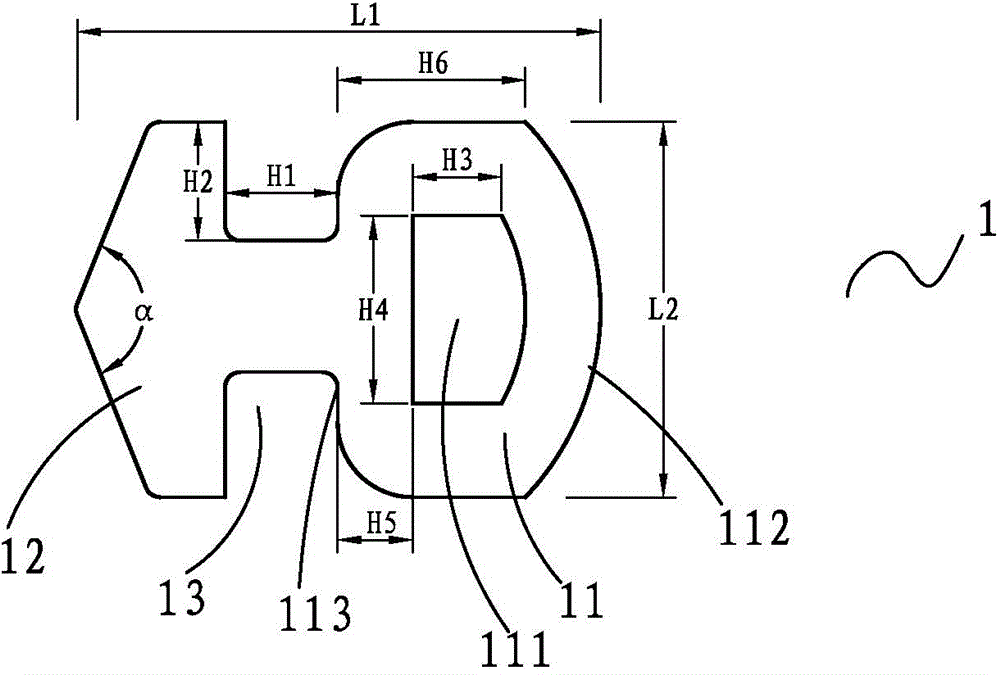

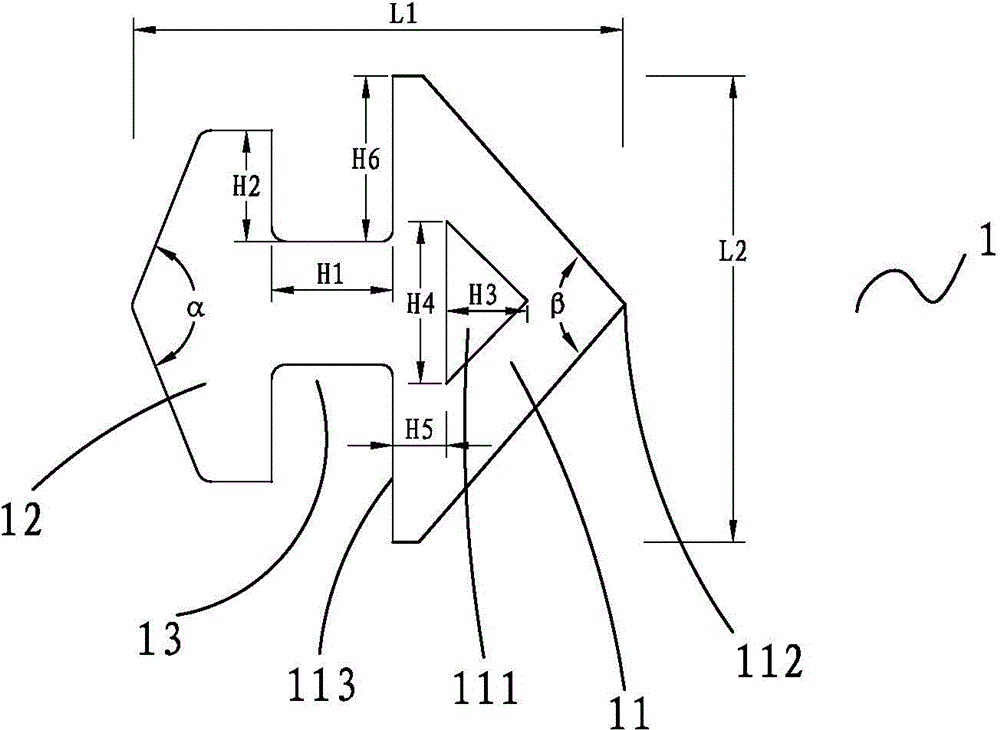

[0028] see figure 1 and figure 2 As shown, a new type of sealing strip of the present invention, the sealing strip 1 includes a main body 11, the main body 11 is provided with a hollow inner cavity 111, and the outer end surface 112 of the main body 11 is a convex arc surface; The inner end surface 113 of the main body 11 is connected to a triangular protrusion 12 protruding outward, and a groove 13 is formed on the upper edge and the lower edge thereof. The main body 11 is provided with a hollow inner cavity 111, so that the compression amount of the sealing strip 1 is larger during compression, the compression range is wider, and the sealing strip 1 is softer and has better sealing performance; the outer end surface 112 of the main body 11 It is a convex arc surface, which is used in the wall member 3 or the inner corner member 4 to reduce the contact area of the sealing strip 1 during disassembly and assembly, reduce friction, make disassembly and assembly easier, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com