Multi-function injector drive controller

A technology for driving controllers and injectors, applied in engine control, fuel injection control, electrical control, etc., can solve problems such as difficult control of precision, many external circuit devices, and high requirements for boost modules, and solve the problem of fuel injection overlap. , easy to control equipment, solve the effect of taking up more resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

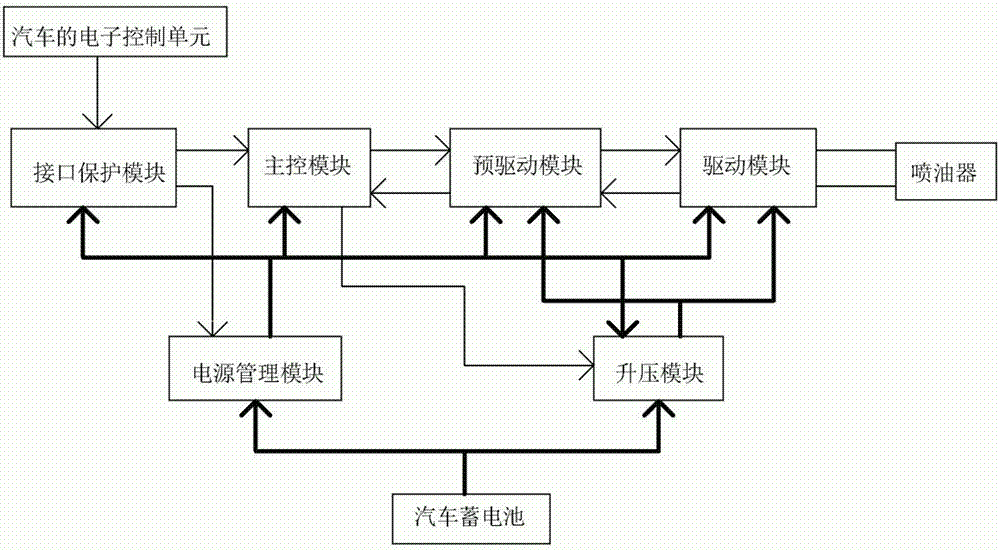

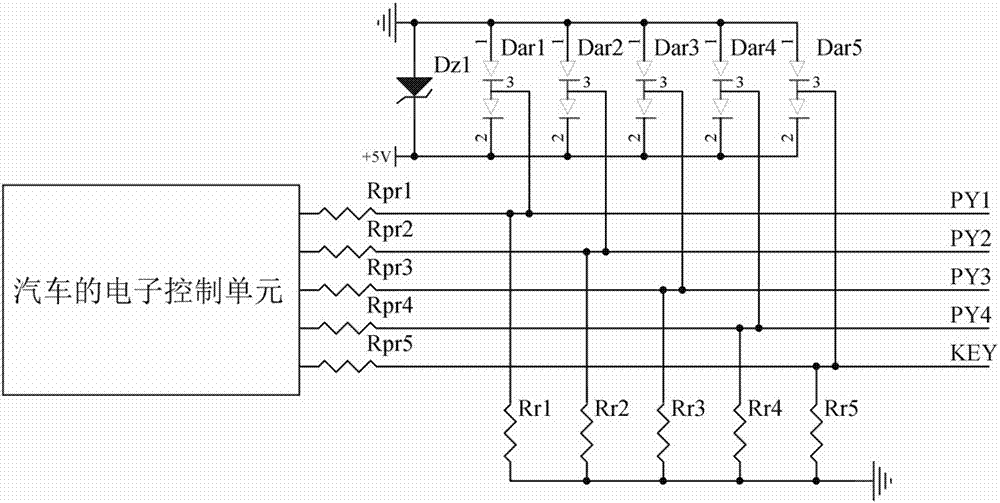

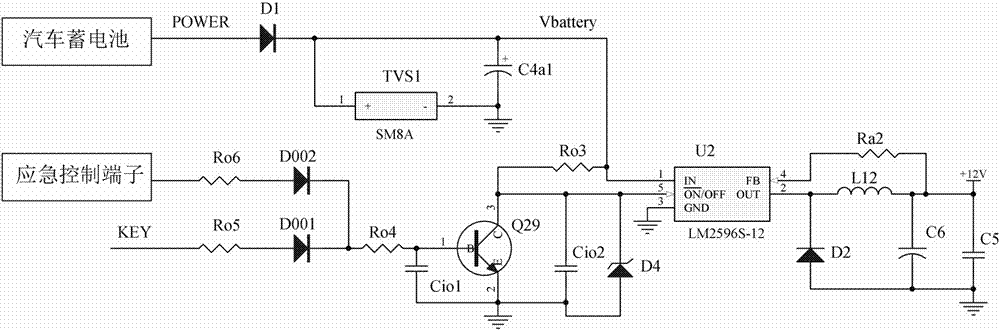

[0033] See Figure 1 ~ Figure 7 In the figure, the multi-function fuel injector drive controller contains interface protection module, main control module, pre-drive module, drive module, boost module and power management module, and the fuel injection output from the electronic control unit ECU (Electronic Control Unit) of the automobile The control signal is input to the main control module after passing through the interface protection module, the drive signal output by the main control module enters the drive module after the pre-drive module, the drive module controls the operation of the injector, and the injector current detection signal output by the drive module is pre-driven After the module is fed back to the main control module, the boost module provides high voltage for the pre-drive module and the drive module, and the power management module provides power for the interface protection module, the main control module, the pre-drive module, the drive module and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com