Pipe fitting structure

A pipe fitting and connecting pipe technology, applied in the field of combined pipe fittings, can solve problems such as inconvenient rotation, inconvenient use, and complex structure, and achieve the effects of easy assembly and fixing, reduced production costs, and improved user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

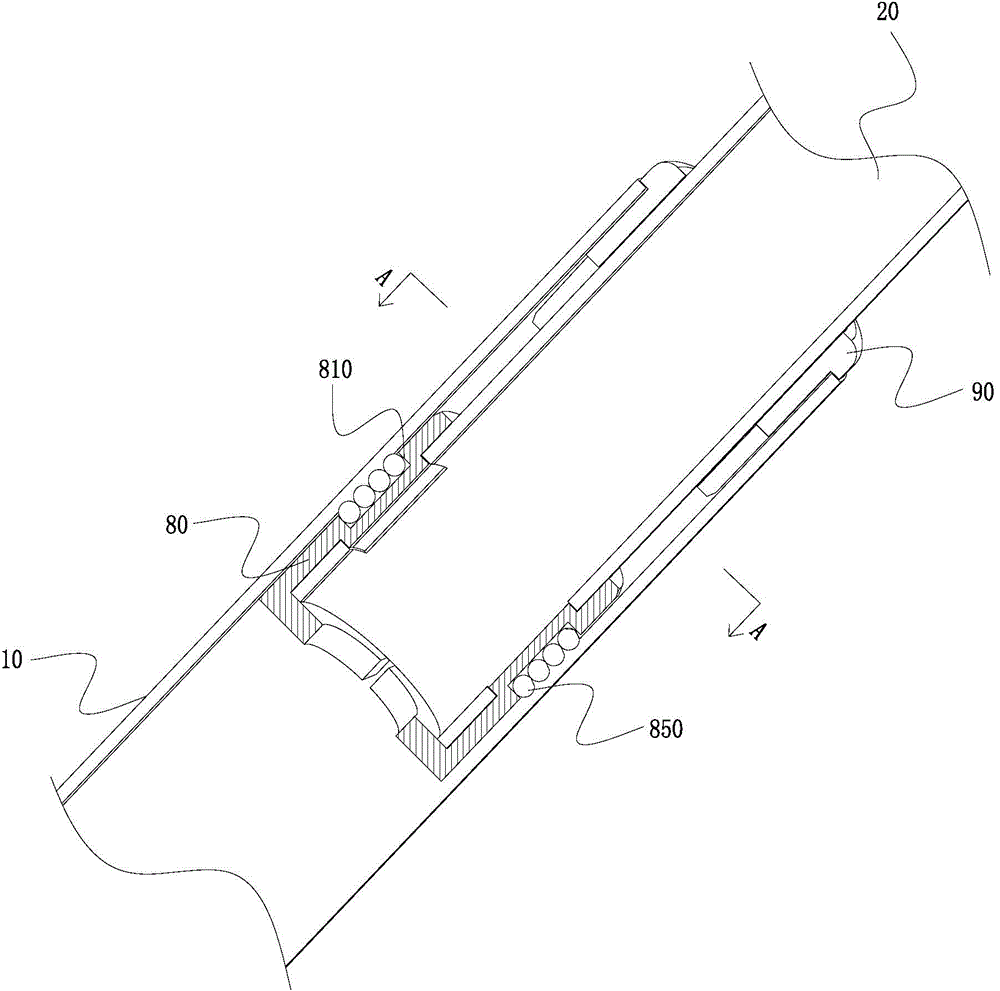

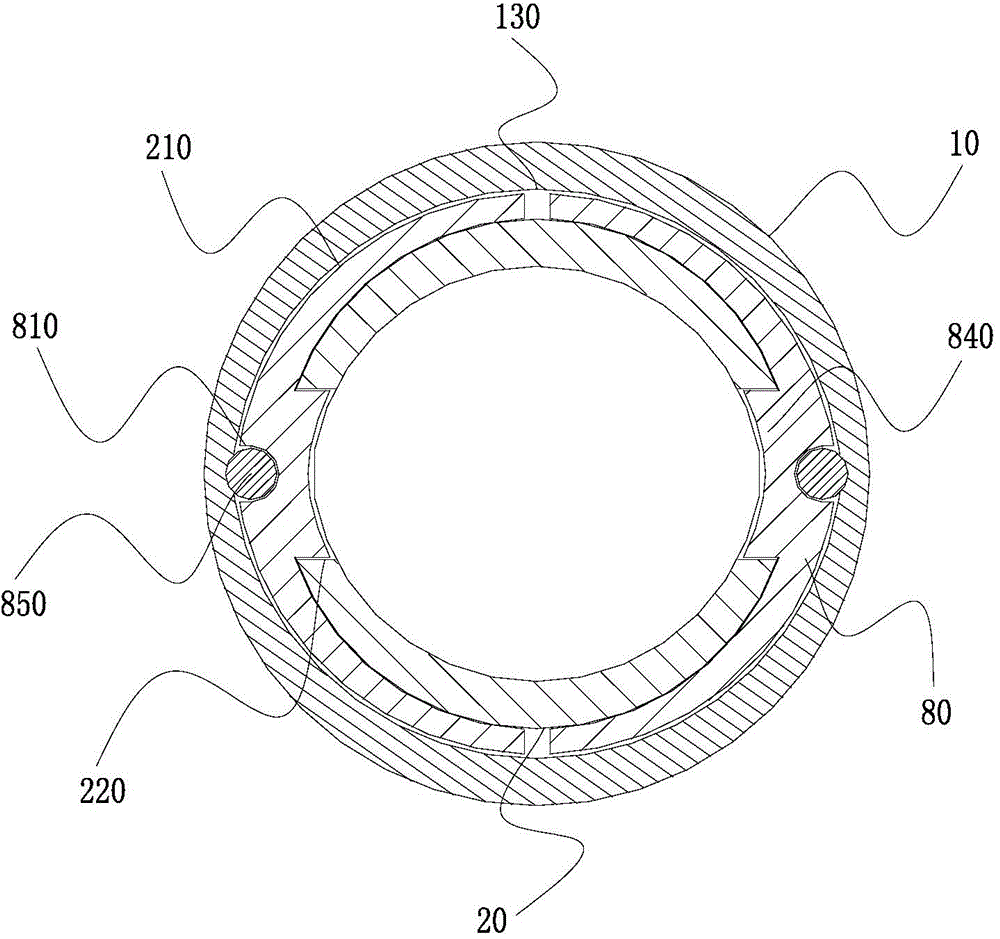

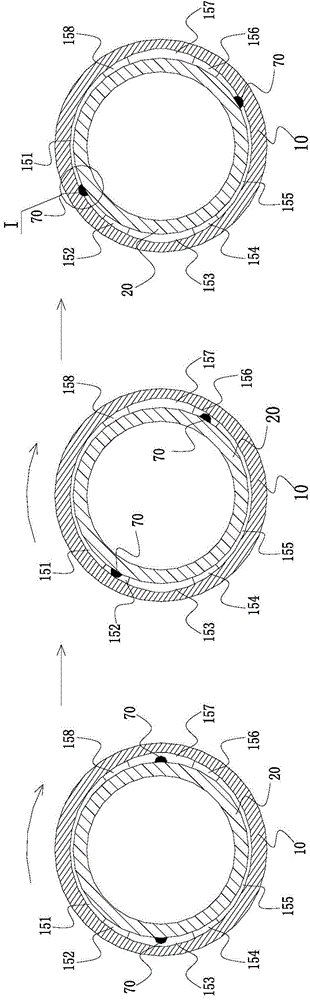

[0037] like Figure 1 to Figure 5As shown, the pipe fitting structure at least includes a first connecting pipe 10 and a second connecting pipe 20 sleeved in the first connecting pipe. The first connecting pipe 10 is provided with a first mating surface 130, and the second connecting pipe 20 is provided with a The second mating portion 210 opposite to the first mating surface 130, the first mating surface 130 is sequentially formed with at least a first interference fit area 151, a first transition fit area 152, a first clearance fit area 153, and a second transition fit area along the circumferential direction. The fit zone 154, the second interference fit zone 155, the third transition fit zone 156, the second clearance fit zone 157 and the fourth transition fit zone 158, the two convex parts 70 on the second fit part 210 and the second A mating surface 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com