Lens barrel

A lens and lens barrel technology, applied in the direction of instruments, installation, optics, etc., can solve the problems of not considering the advance and retreat of moving frame parts, not much consideration of abnormal sound, noise, etc., to achieve noise realization, suppression of abnormal sound, and high-precision action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

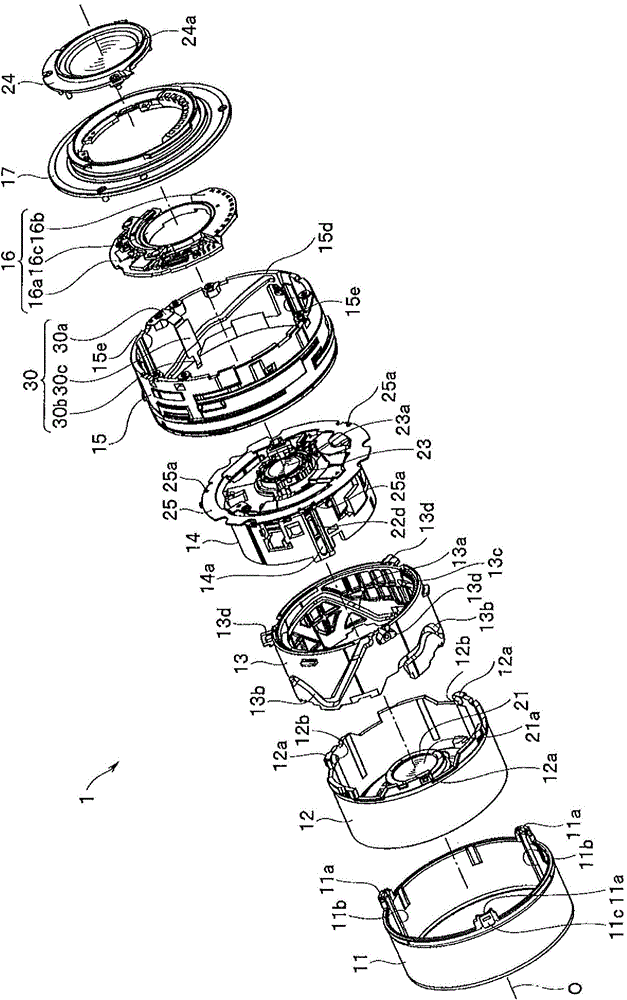

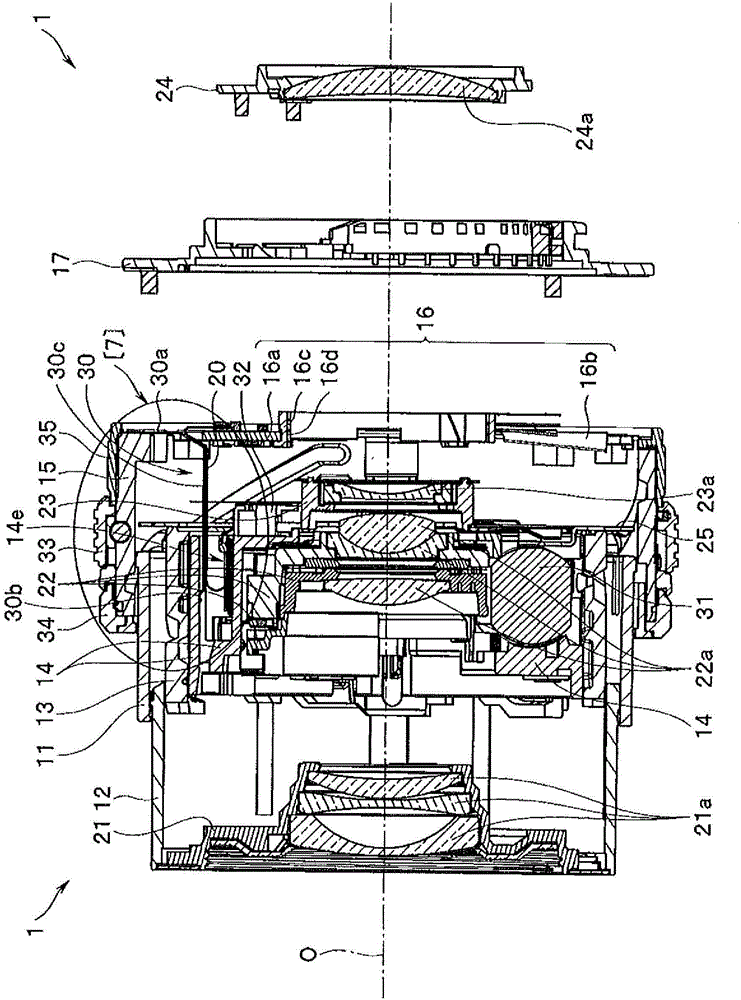

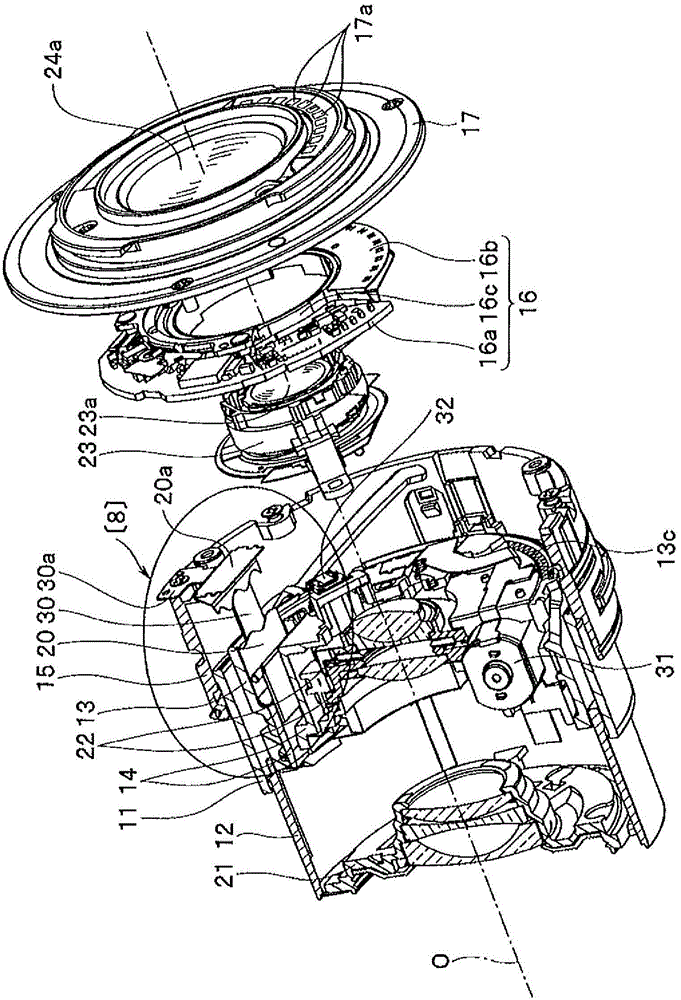

[0021] Hereinafter, the present invention will be described with reference to the illustrated embodiments. One embodiment of the present invention illustrates, for example, a lens barrel applied to an imaging device such as a digital camera or a video camera (hereinafter simply referred to as a camera). It is an imaging optical system that forms a subject image, and can move a part of the optical lens groups among the plurality of optical lens groups constituting the imaging optical system in a direction along the optical axis.

[0022] In addition, in the present embodiment, the optical axis of the photographing optical system in the lens barrel is denoted by a symbol O. In the direction along the optical axis O, the side where the subject is located opposite to the front surface of the camera (not shown) equipped with the lens barrel is referred to as the front. The side where the head is located is called the rear.

[0023] In addition, in each drawing used in the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com