Metal steam discharger lamp

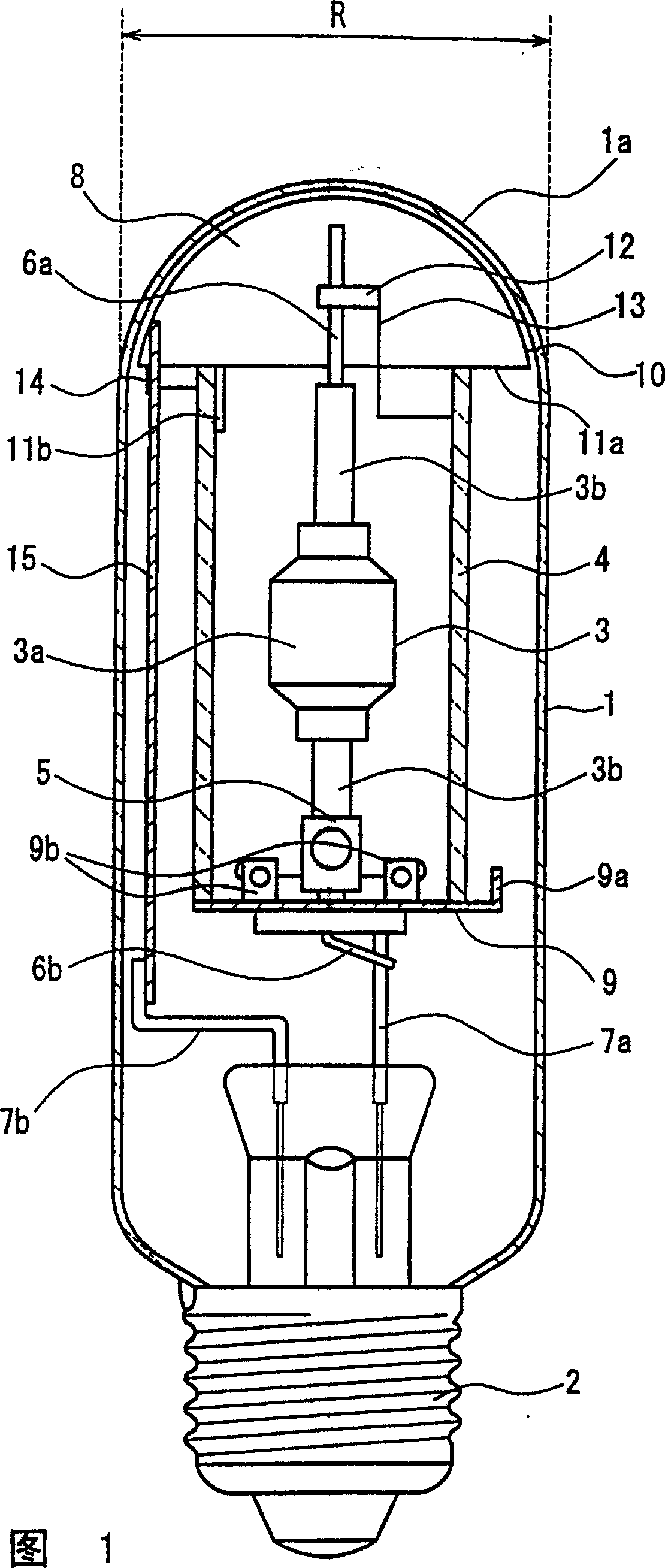

A metal vapor, discharge lamp technology, applied in the direction of gas discharge lamp parts and other directions, can solve the problems of abnormal sound of the outer tube, decreased luminous flux, friction of tongue pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

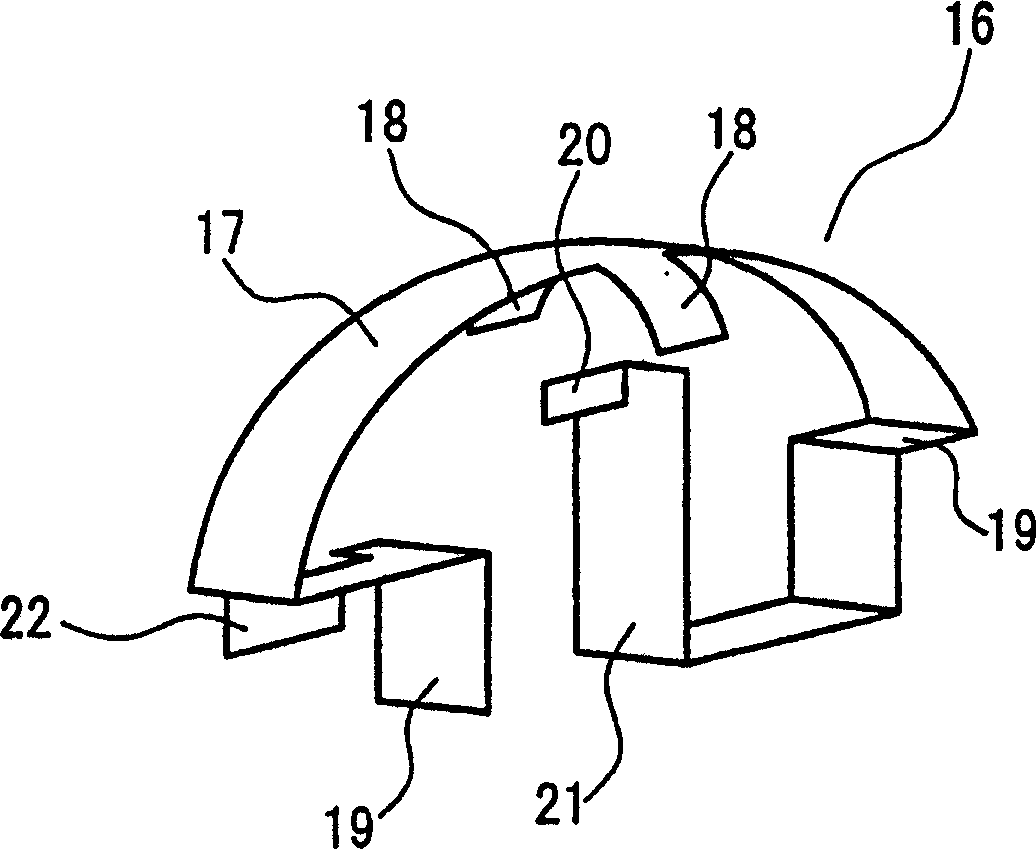

[0076] Next, the metal halide lamp with rated electric power of 150W according to the second embodiment of the present invention, such as image 3 As shown, except that the supporting body 16 is provided with the protruding part 18 that is close to the closed part 1a of the outer tube 1 and protrudes from the pillar part 17, it has the same features as the metal halide lamp with a rated electric power of 150W in the first embodiment of the present invention. structure.

[0077] The protruding portion 18 has a plate shape with a length of 10 mm and a width of 5 mm, is provided at the center of the pillar portion 17 , and protrudes substantially perpendicular to the pillar portion 17 . That is, the pillar portion 17 and the protruding portion 18 form a cross shape. The pillar portion 17 and the protruding portion 18 are formed of one plate.

[0078] image 3 Among them, 19 denotes a sleeve holding portion, 20 denotes a power supply body connection portion, 21 denotes an elast...

Embodiment 3

[0081] Next, the metal halide lamp with a rated electric power of 150W according to the third embodiment of the present invention is as follows: Figure 4 As shown, in the supporting body 23, except that the elastic body part 26 composed of a stretchable coil spring is interposed between the sleeve holding part 24a and the power supply body connecting part 25, the rest has the same characteristics as the first embodiment of the present invention. The same structure as a metal halide lamp with a rated electric power of 150W.

[0082] The elastic body portion 26 is composed of molybdenum and has a length of 5 mm and a diameter of 5 mm.

[0083] Figure 4 Among them, 24 denotes another sleeve holding portion, 27 denotes a support portion, and 28 denotes an electric power supply line connection portion.

[0084] According to the structure of the third embodiment of the present invention as above, it is possible to firmly support the sleeve 4 while also suppressing the occurrence...

Embodiment 4

[0087] The halogen lamp with a rated electric power of 150W in the fourth embodiment of the present invention is as Figure 5 As shown, in the support body 29, except that the sleeve holders 31a, 31b are arranged with the outer tube 1 shown in FIG. 1 ( Figure 5 Not shown) of the blocking portion 1a ( Figure 5 not shown) side bushing 4 ( Figure 5 (not shown) except for the recessed grooves 30a, 30b with a width of 1.3mm and a depth of 2mm, which are fitted at the ends of the lamp, the remaining structure is the same as that of the halogen lamp rated at 150W in the first embodiment of the present invention.

[0088] Figure 5 Among them, 32 denotes a support portion, 33 denotes a power supply body connection portion, 34 denotes an elastic body portion, and 35 denotes a power supply line connection portion.

[0089] According to the structure of the fourth embodiment of the present invention as described above, the bushing 4 can be firmly supported, and the occurrence of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com