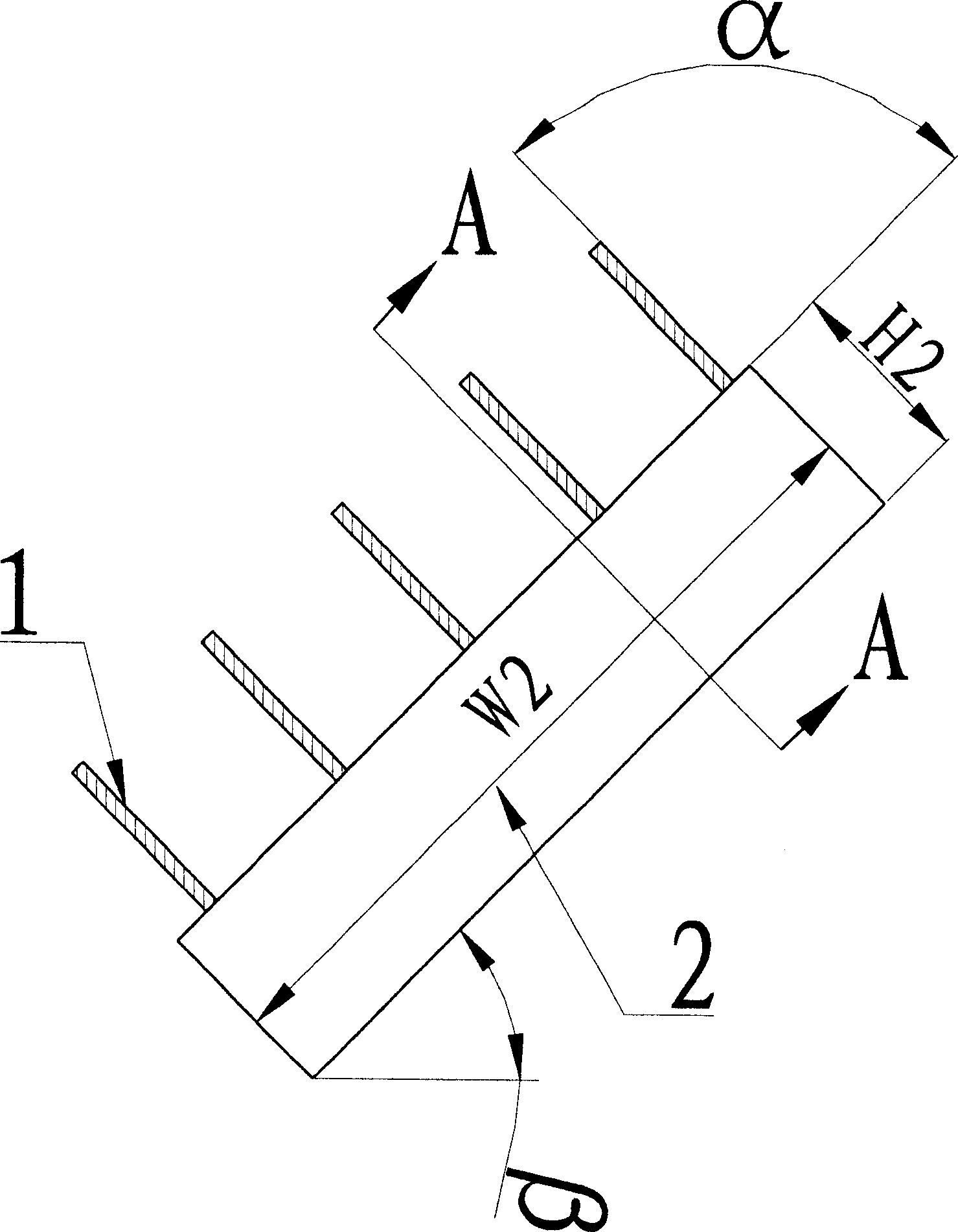

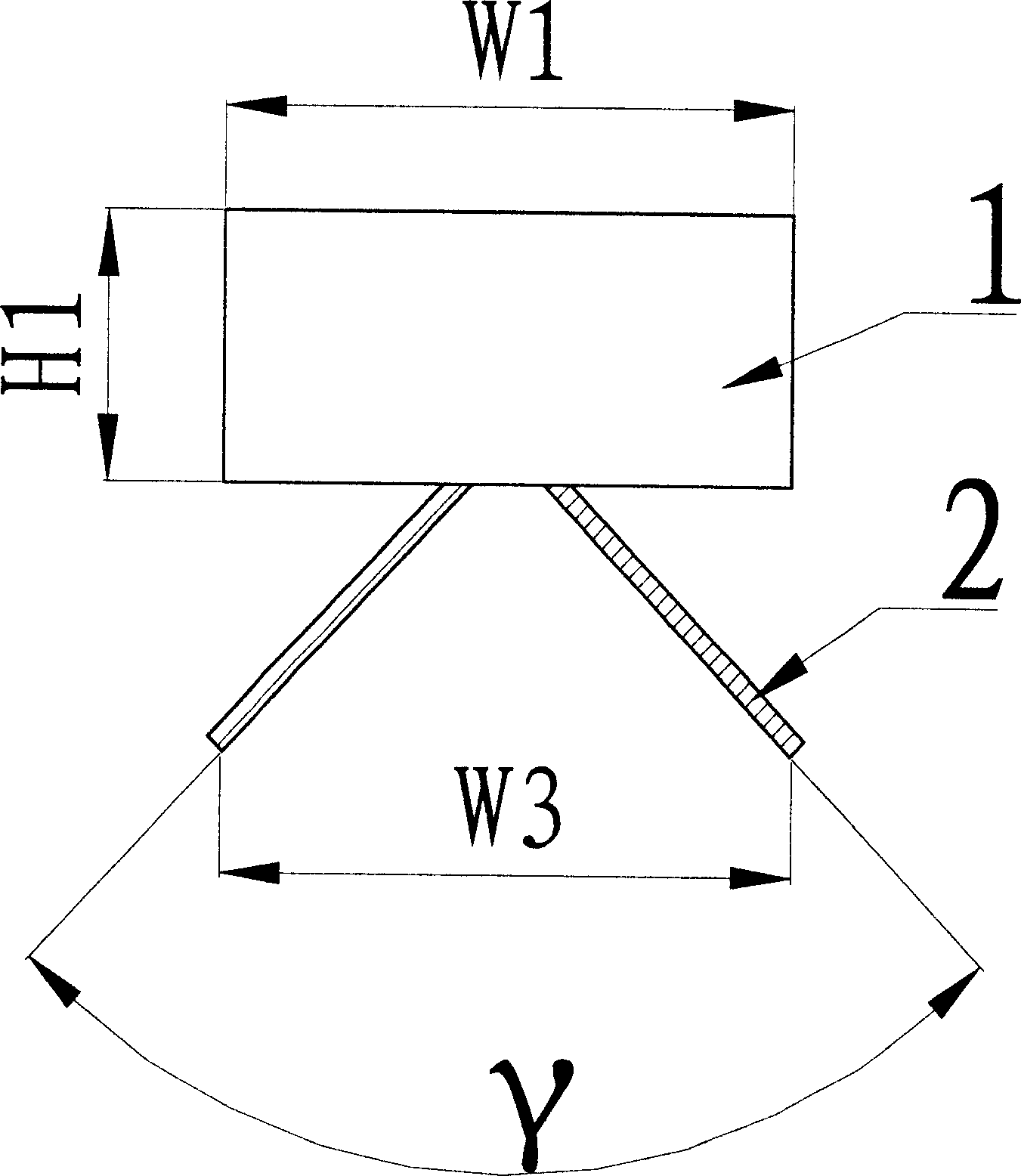

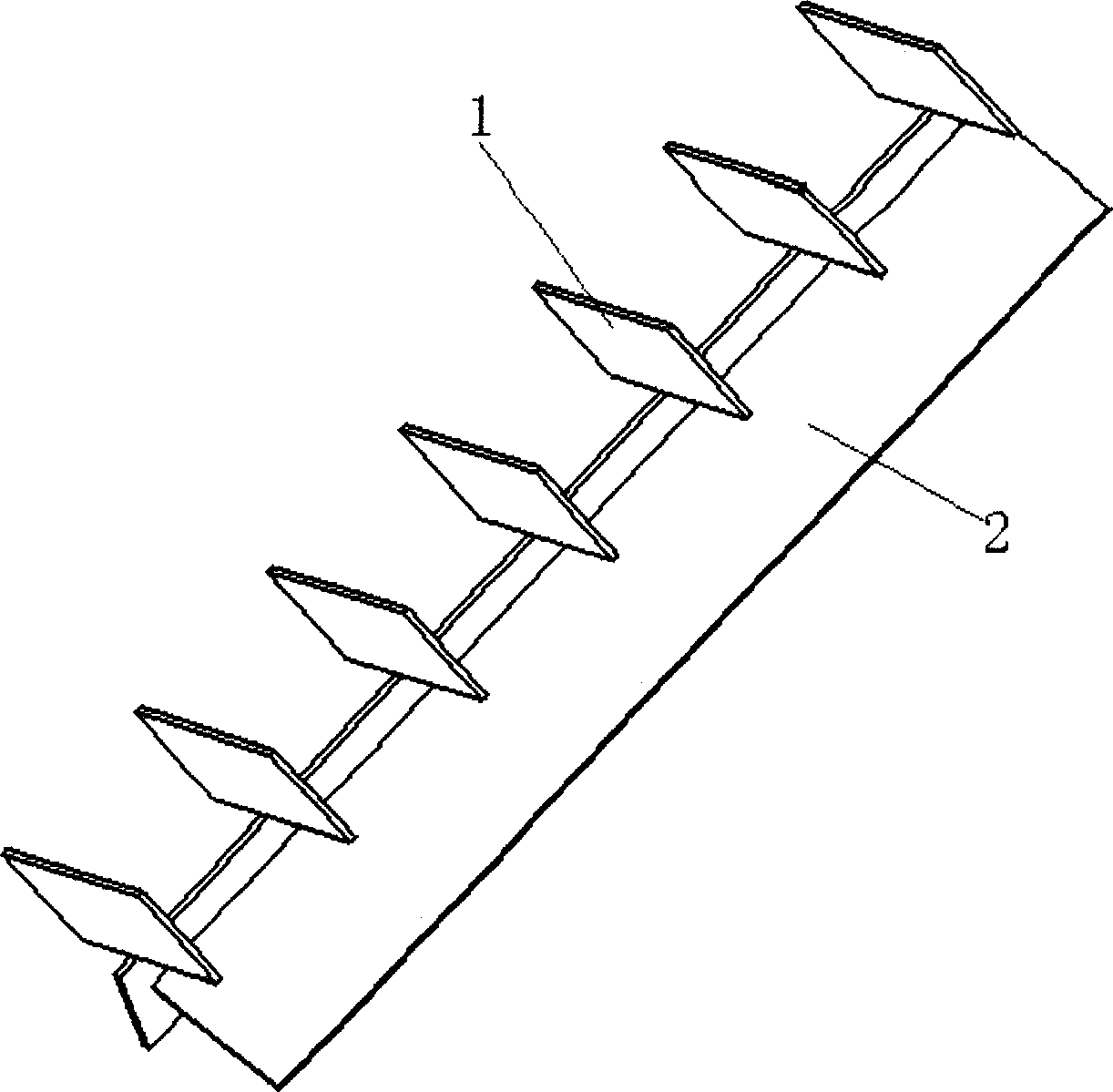

Internal structure of FCC stripper and its arrangement method

A technology for catalytic cracking and internal components, applied in catalytic cracking, chemical instruments and methods, cracking, etc., can solve problems such as oil and gas coking, and achieve the effects of preventing oil and gas coking, large reserves, and increased processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] This embodiment illustrates: the implementation effect of the internal member of the present invention.

[0041] Figure 7 It is a schematic structural diagram of the cold-state experimental device adopted in this embodiment. The device is a circulating fluidized device, as shown in the figure, the catalyst is lifted to the settler 32 in the riser 37, and after the two-stage separation of the swirl head 38 and the cyclone separator 31, it enters the stripping section 33 and is stripped. After completion, it enters the storage bin 34, quantitatively feeds the pre-lifter 36 through the screw feeder 35, and then enters the riser 37 for the next round of circulation. The diameter of the stripping section used in the experiment is 200mm, the total height is 1.5m, the diameter of the riser is 80mm, and the height is 4.5m. In the experiment, carbon dioxide gas was used as the fluidization gas in the stripping section 33, and the air entrained by the catalyst particles flowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com