A Hybrid Drive Reconfigurable Five-bar Mechanism Experiment Bench

A five-bar mechanism and hybrid drive technology, applied in the field of machines and mechanisms, can solve problems such as small movement space, inability to quickly reconfigure, poor rigidity, etc., and achieve stable movement performance and a wide range of working planes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

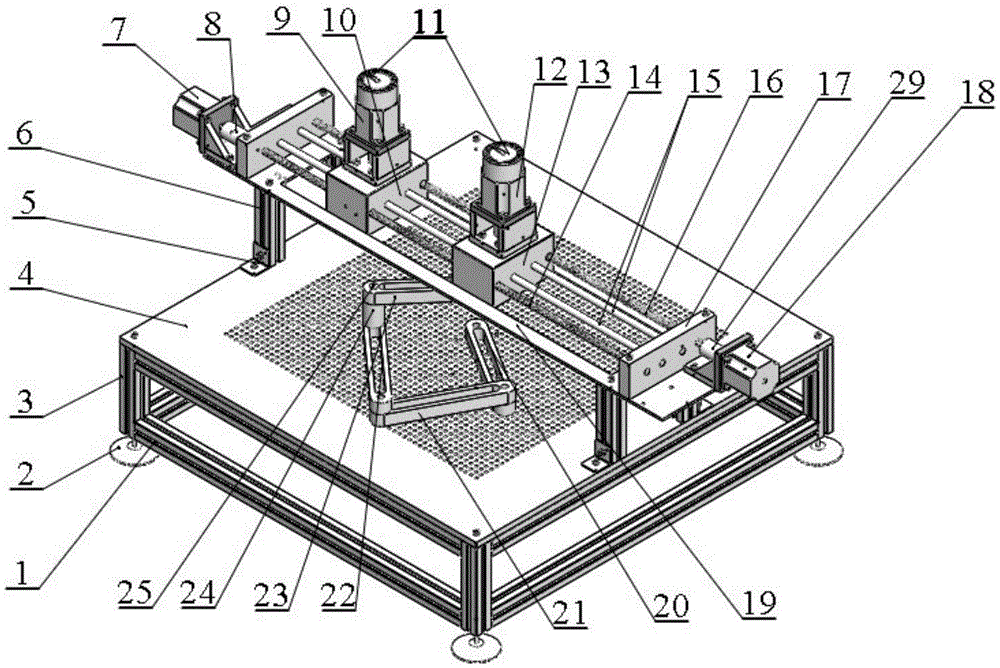

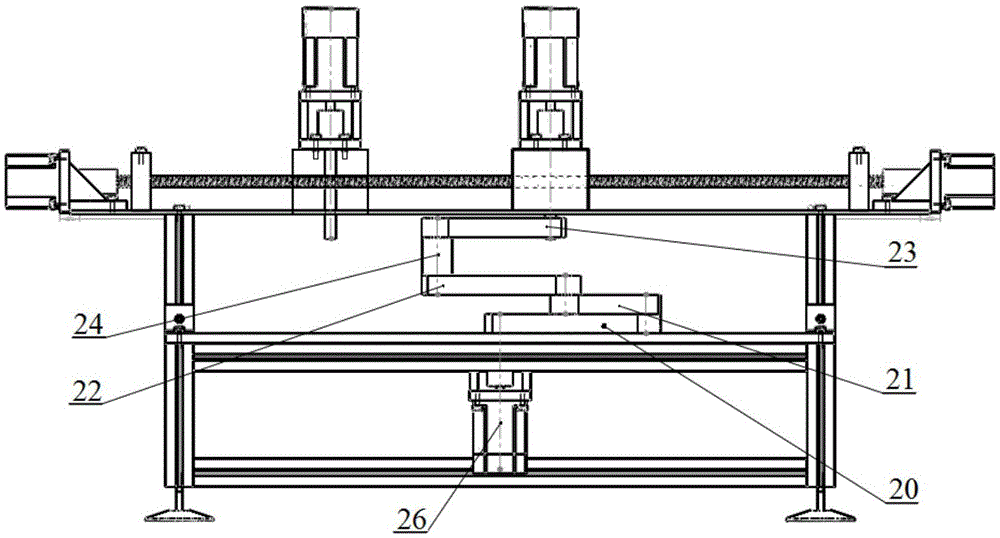

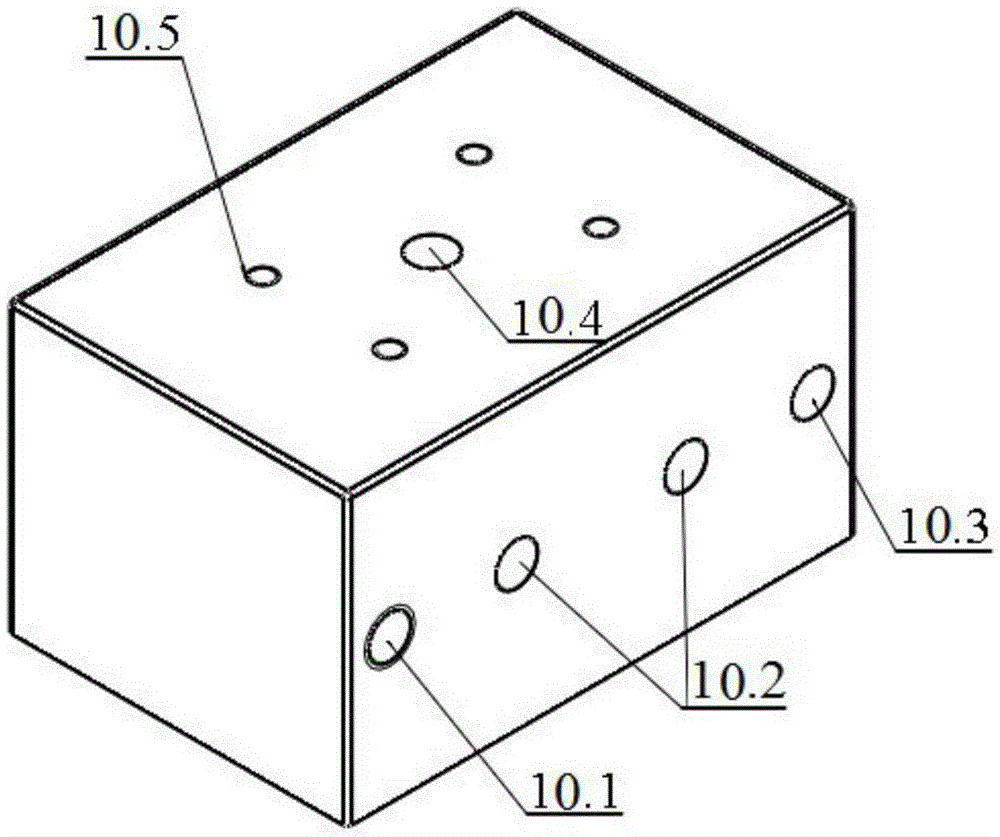

[0028] Such as figure 1 , figure 2 As shown, a hybrid drive reconfigurable five-bar mechanism test bench includes a working platform, a reconfigurable five-bar mechanism and a frame length adjustment device. The working platform includes eight A-shaped grooved profiles 1 and four B-shaped belts Groove profile 3, anchor bolt 2, coordinate table 4 and No. II servo motor 26, eight A-shaped grooved profiles 1 form two equilateral rectangular frames, and the two equilateral rectangular frames are distributed in two layers up and down, and two up and down The equilateral rectangular frame is connected with the B-shaped grooved profile 3 through bolts, the coordinate table 4 is set on the upper equilateral rectangular frame to form a working platform, and the anchor bolts 2 are set on the lower end surface of the B-shaped grooved profile 3 as a working platform. The supporting feet of the table top, the motor support of No. II servo motor 26 is arranged on the lower surface of the ...

Embodiment 2

[0035] Hybrid drive reconfigurable five-bar mechanism test bench with different axis reconfiguration modes of the original moving parts:

[0036] Such as Image 6 , Figure 7 As shown, one end of No. I driving part 20 is synchronously connected with the motor shaft of No. II servo motor 26, and the lower end surface of No. I driving part 20 is parallel to the coordinate table 4, and the other end of No. I driving part 20 is connected to I One end of No. connecting rod 21 is connected, the other end of No. I connecting rod 21 is connected with one end of No. II connecting rod 22, and the other end of No. II connecting rod 22 is connected to No. II driving member 23 through No. I connecting mandrel 25 One end of No. 1 mating sleeve 24 is sleeved on the outside of No. 1 connecting mandrel 25, and the other end of No. 2 prime mover 23 is synchronously connected with the motor shaft of No. 2 stepping motor 12. The No. III stepping motor drives the second ball screw to rotate so a...

Embodiment 3

[0037] Example 3 Experimental bench for hybrid drive reconfigurable five-bar mechanism in coaxial center reconfiguration mode of primary moving parts:

[0038] Such as Figure 8 , Figure 9 As shown, one end of No. I driving part 20 is synchronously connected with the motor shaft of No. II servo motor 26, and the lower end surface of No. I driving part 20 is parallel to the coordinate table 4, and the other end of No. I driving part 20 is connected to I One end of No. connecting rod 21 is connected, the other end of No. I connecting rod 21 is connected with one end of No. II connecting rod 22, and the other end of No. II connecting rod 22 is connected to No. II driving member 23 through No. I connecting mandrel 25 One end of No. 1 mating sleeve 24 is sleeved on the outside of No. 1 connecting mandrel 25, and the other end of No. 2 prime mover 23 is synchronously connected with the motor shaft of No. 2 stepping motor 12. The No. III stepping motor drives the second ball screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com