Scribing combined tool for pasting strain gage of fuel assembly

A technology for fuel assemblies and strain gauges, applied in manufacturing tools, workshop equipment, etc., can solve the problems of difficult implementation, difficulty in precise marking, and inaccurate marking positions, and achieve convenient installation and positioning, convenient positioning, and accurate marking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

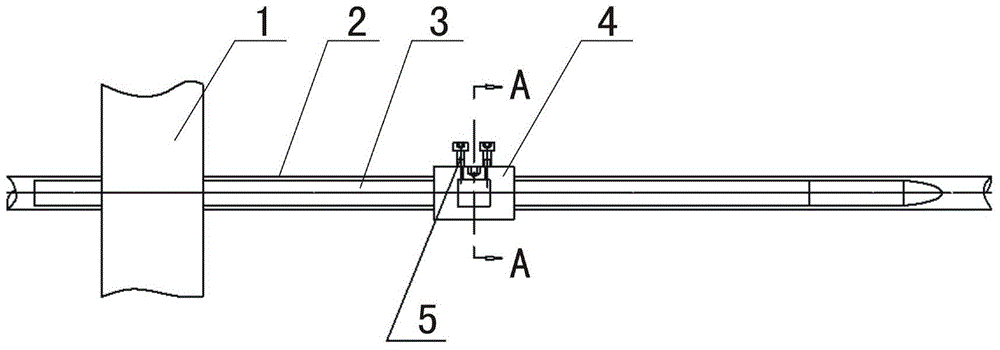

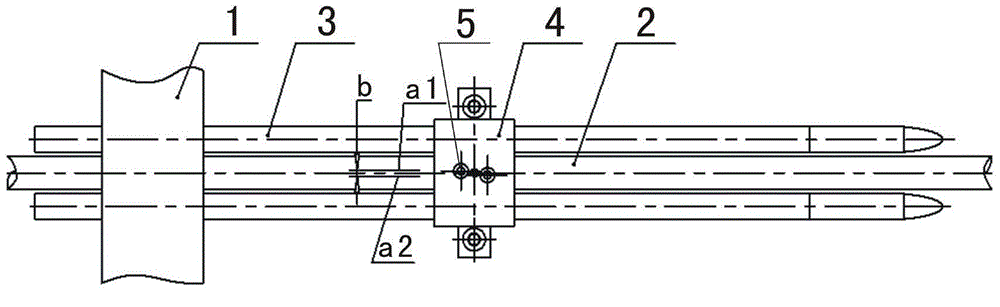

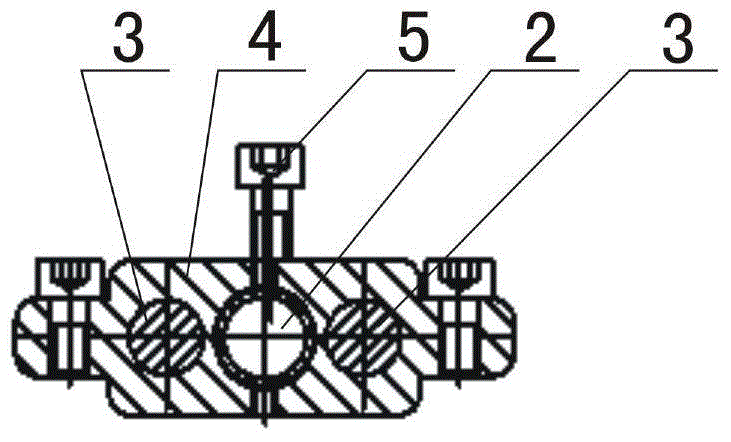

[0036] Such as Figure 1-Figure 10As shown in the present invention, the combined tooling for pasting and scribing of fuel assembly strain gauges according to the present invention is used for scribing on the guide pipe 2 of the fuel assembly, including a guide rod 3, a scribing block 4, a scribing screw 5 and Positioning plate 6, two guide rods 3 are installed on both sides of the guide pipe 2 respectively, the guide rods 3 are used to be installed in the grid 1 of the fuel assembly and the outer diameter of the rod body is the same as the fuel assembly of the fuel assembly. Rods (not shown) are identical; Marking block 4 is provided with the guide rod through hole 46 that is used for guide rod 3 to pass parallel to each other and is used for the guide tube through hole 45 that guide tube 2 passes, and marking block 4 There are two guide rod through-holes 46 and they are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com