Liquid temperature processing system and method

A liquid temperature and processing system technology, applied in signal transmission systems, radiation pyrometry, measuring devices, etc., can solve the problems of breastfeeding, single function, too cold milk, etc., and achieve the effect of clean, hygienic and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

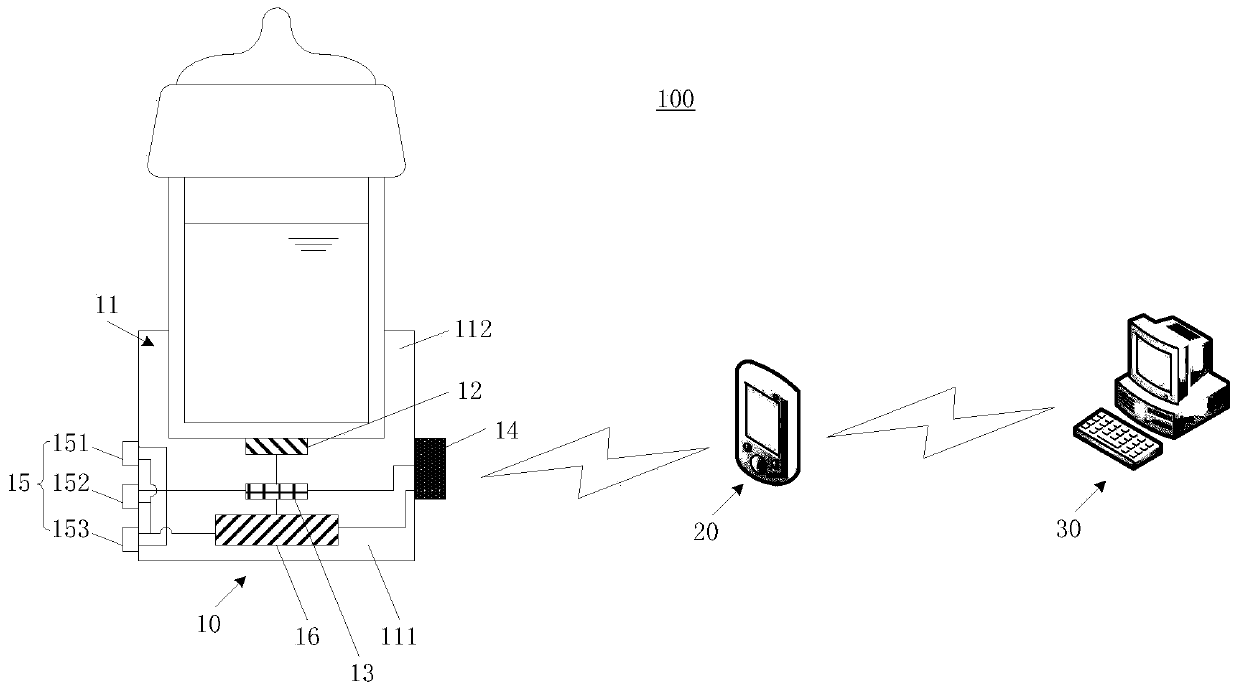

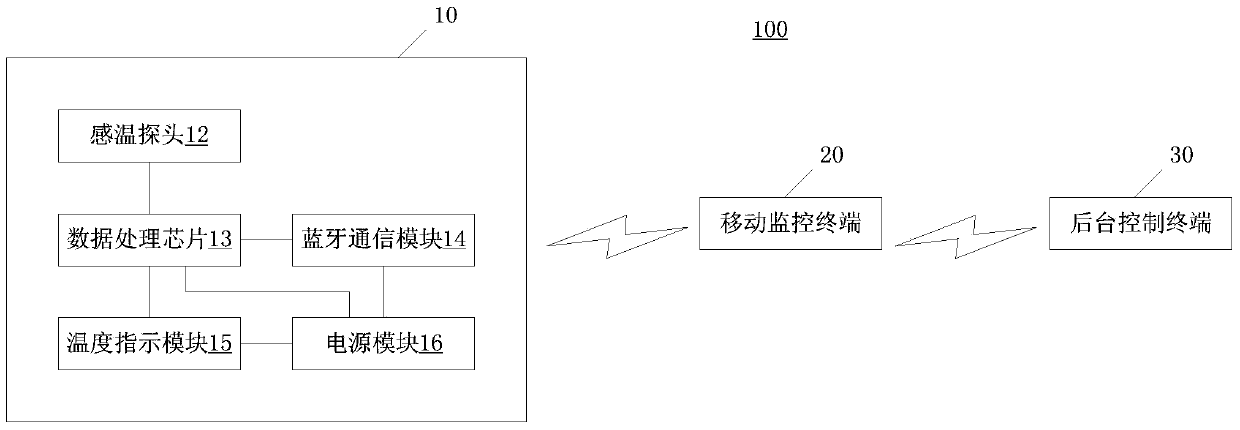

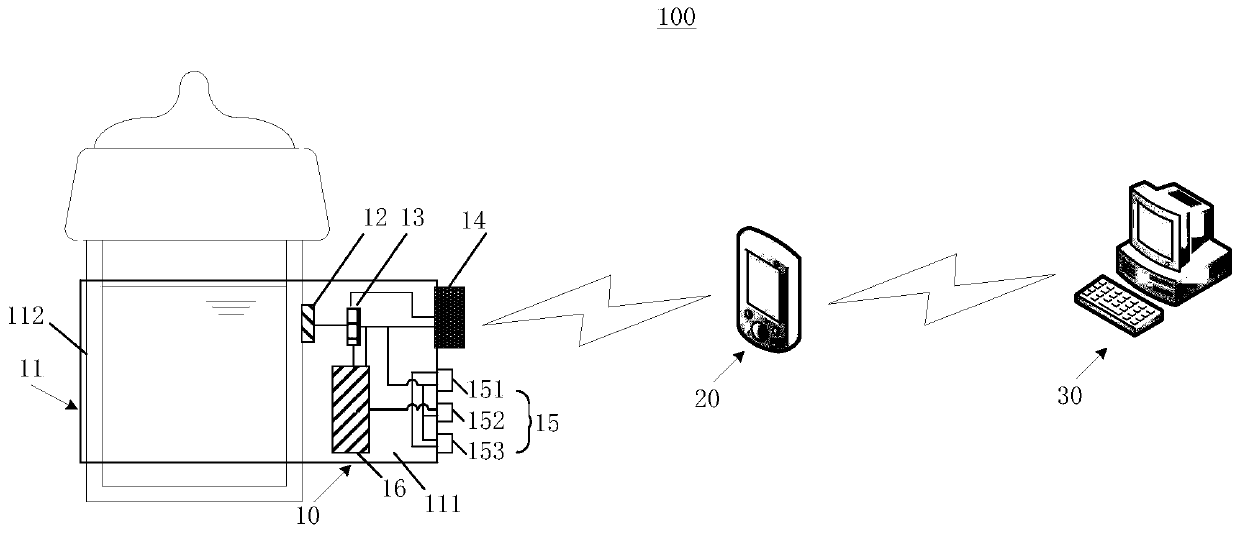

[0037] see figure 1 and figure 2 , a preferred embodiment of the present invention provides a liquid temperature processing system 100, the liquid temperature processing system 100 can be used to sense the temperature of the liquid in the food container, in this embodiment to sense the temperature of the milk in the bottle is Specific examples to introduce its structure and function in detail.

[0038] The liquid temperature processing system 100 includes a temperature sensing terminal 10 , a mobile monitoring terminal 20 and a background control terminal 30 . The temperature sensing terminal 10 is used to sense existing feeding bottles (such as figure 1The temperature of the milk in the shown feeding bottle), and the sensed temperature data is sent to the mobile monitoring terminal 20 by means of short-range wireless communication (such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com