An oil cylinder lifting type lifting brake test bench

A braking test and braking platform technology, which is used in vehicle testing, machine/structural component testing, measuring devices, etc., to achieve the effects of simple device structure, accurate detection, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

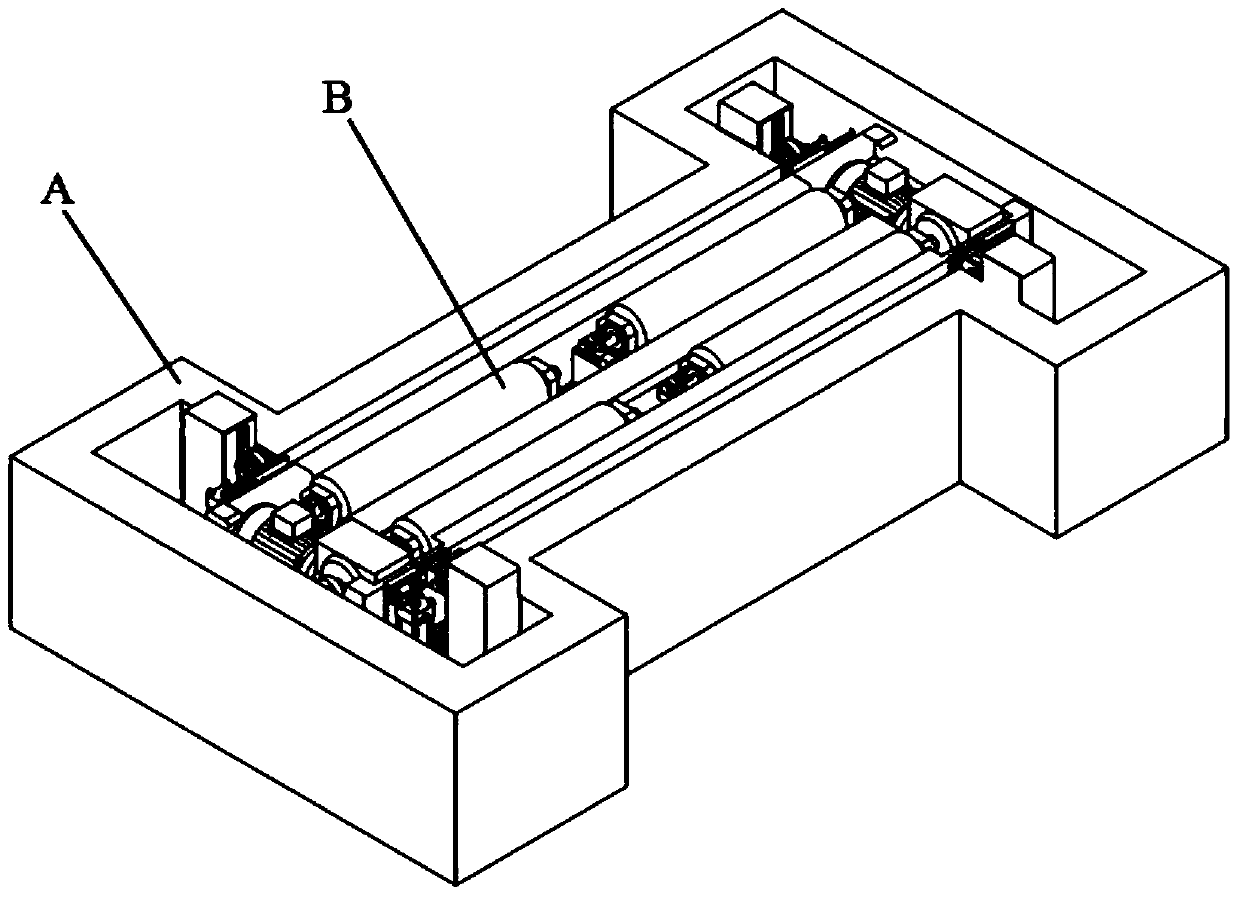

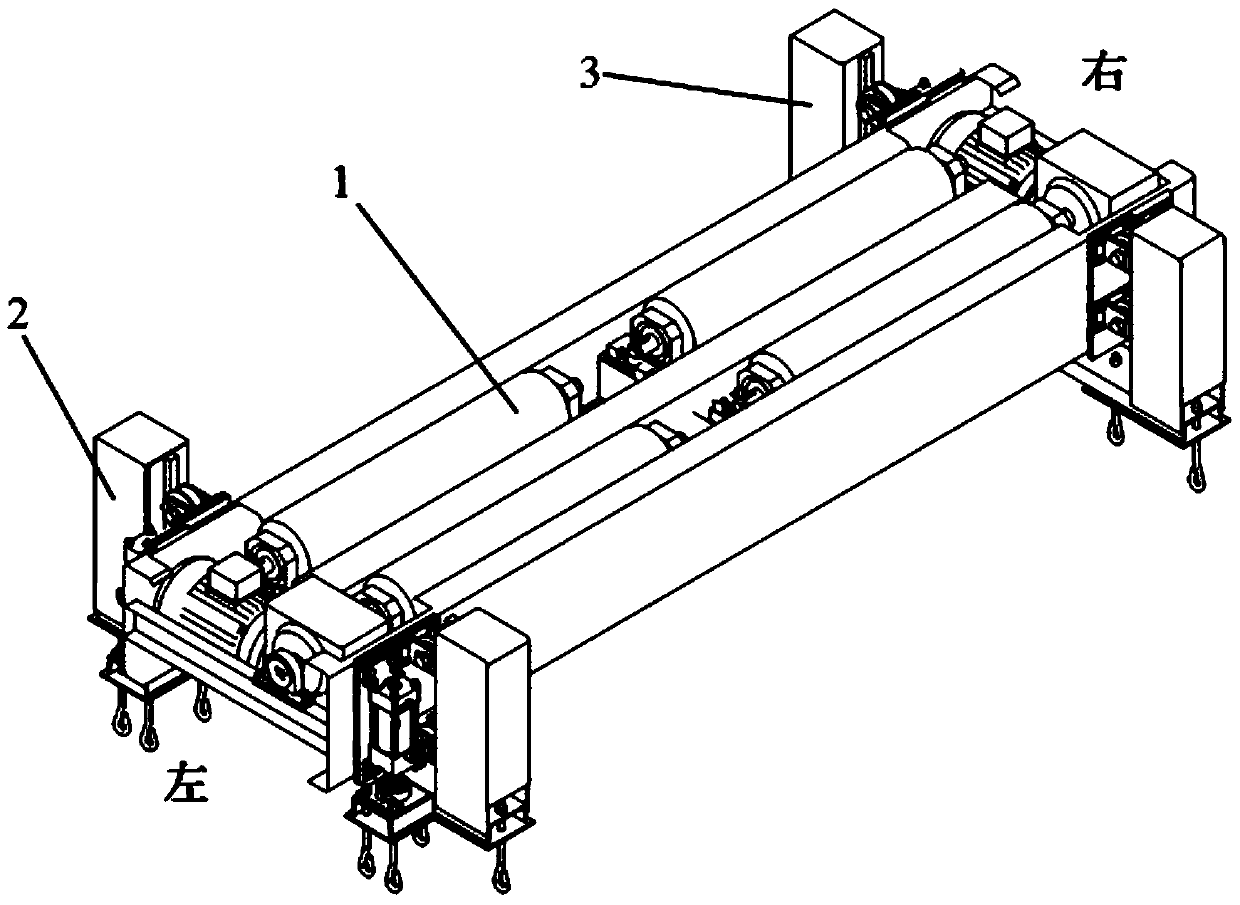

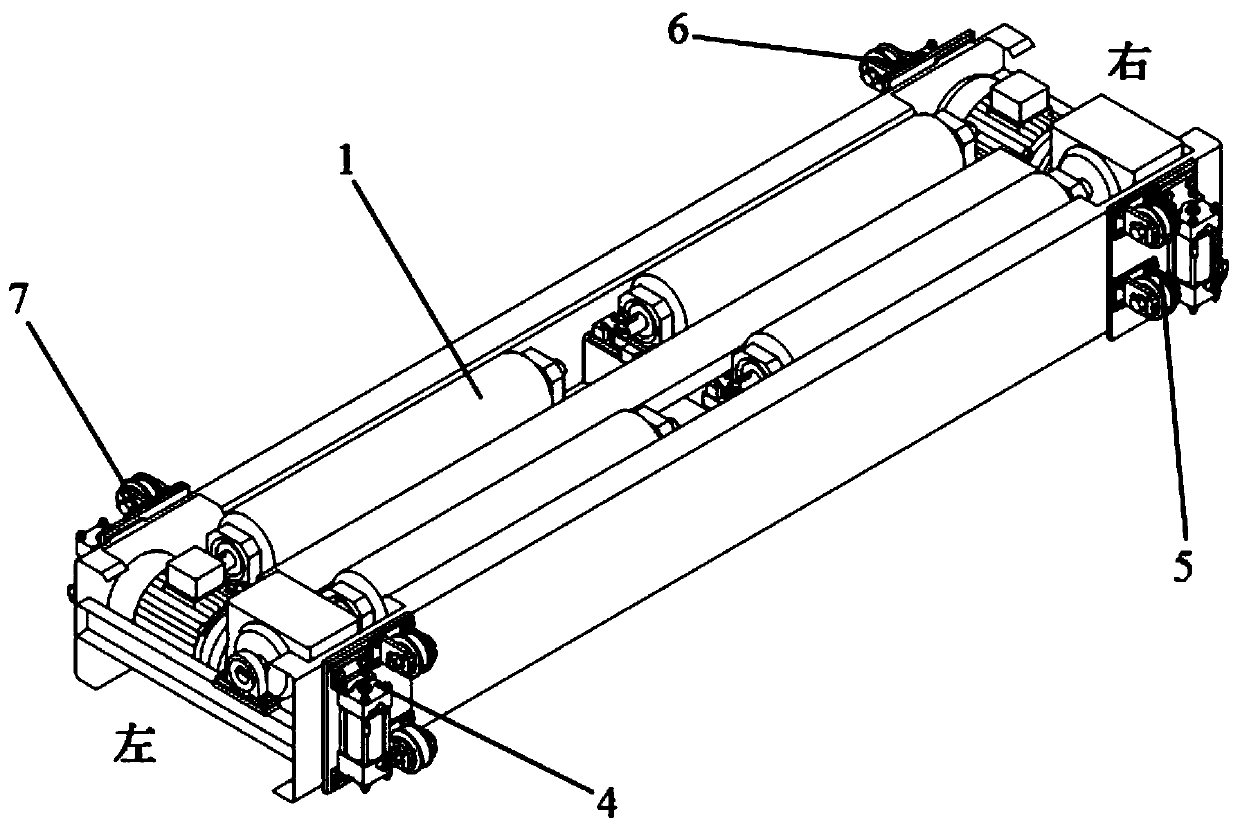

[0030] refer to Figure 1 to Figure 3 As shown, the oil cylinder lifting type lifting brake test bench B of the present invention is horizontally installed in the foundation A; Support frame assembly 2, No. 2 sensor and guide rail support frame assembly 3, No. 1 oil cylinder guide wheel assembly 4, No. 2 oil cylinder guide wheel assembly 5, No. 3 oil cylinder guide wheel assembly 6 and No. 4 oil cylinder guide wheel assembly body 7 composition.

[0031] refer to Figure 4 As shown, the No. 1 oil cylinder guide wheel assembly 4 of the present invention consists of an oil cylinder installation welding plate 8, No. 1 oil cylinder support 9, No. 2 oil cylinder support 10, oil cylinder main body assembly 11, No. 1 guide wheel support 12 , No. one guide wheel 13, No. two guide wheel support 14 and No. two guide wheel 15 form. The No. 1 oil cylinder support 9 and the No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com