Electric bicycle braking performance testing machine

A technology of electric bicycles and testing machines, which is applied in the direction of vehicle testing, machine/structural component testing, and measuring devices. It can solve the problem of wheel instability, reduce the functionality of the testing machine, and reduce the convenience of using the electric bicycle braking performance testing machine. Sexuality and other issues, to achieve the effect of improving functionality and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

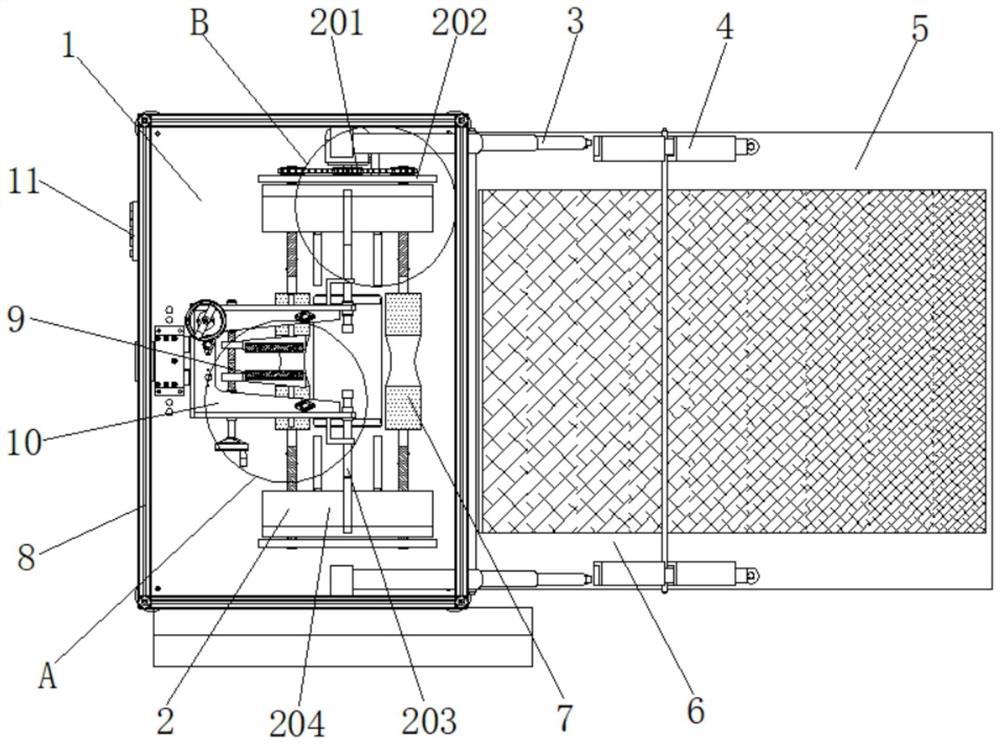

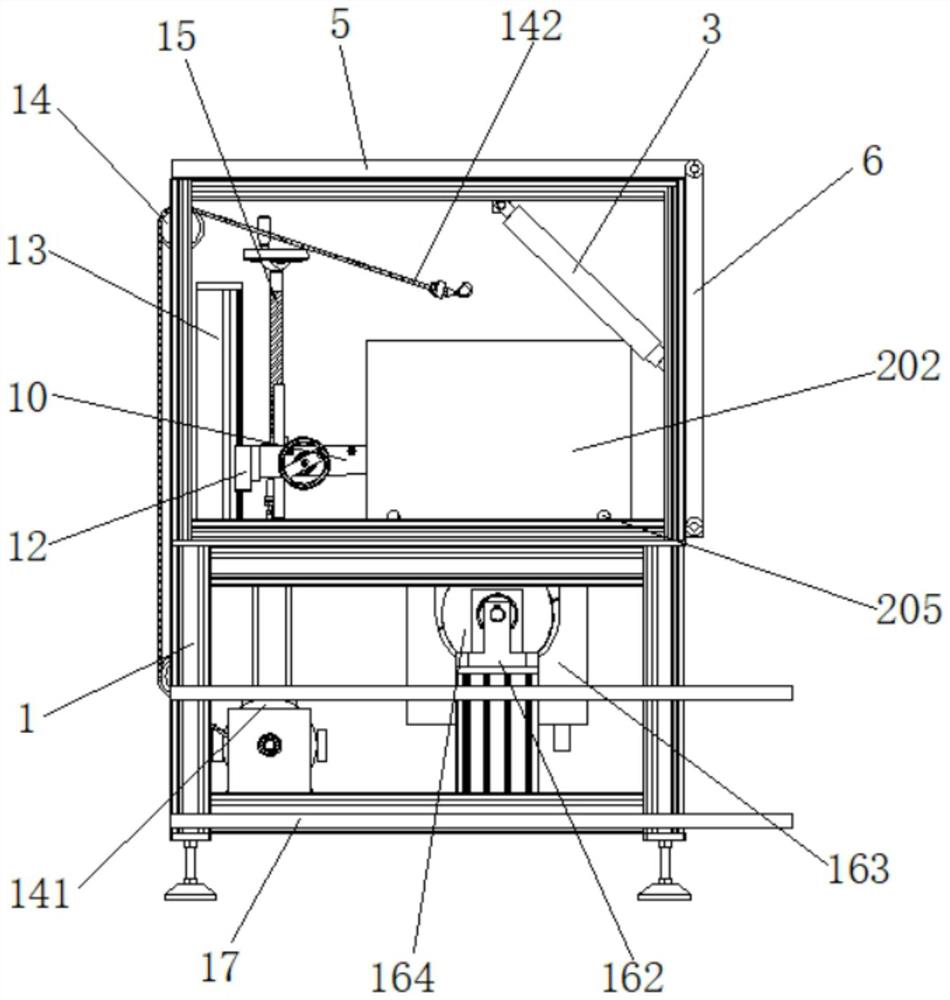

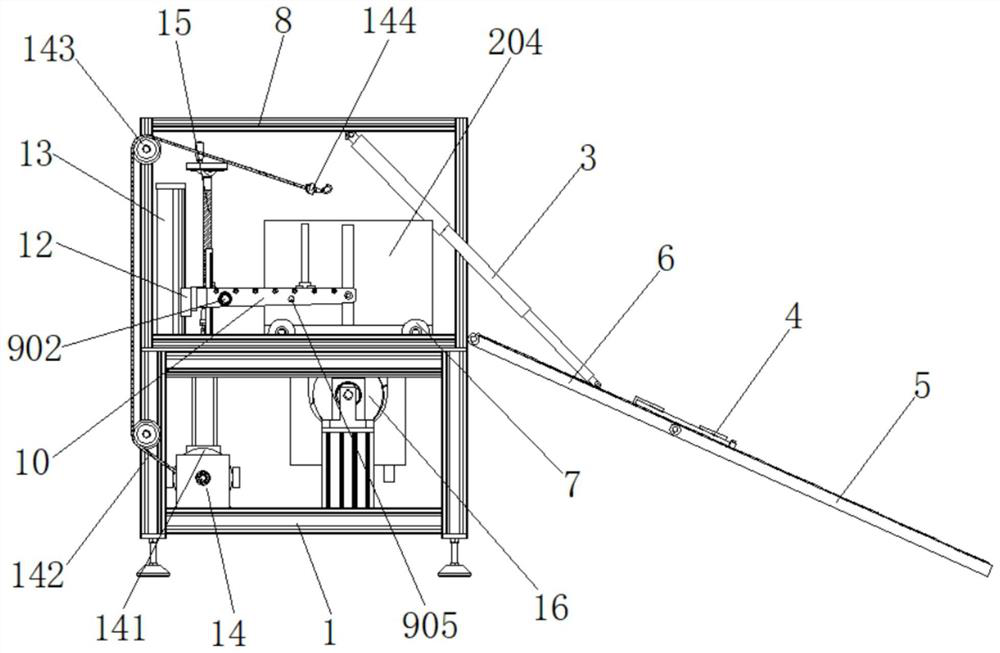

[0039] Example 1, such as Figure 1-8 As shown, dry braking performance test:

[0040] A. For hand-operated brakes, apply a vertical force sufficient to prevent the tires from slipping on the rollers on the bicycle. After accelerating the driving mechanism to the specified speed, apply a series of operating forces with increments of 20N from 40N until 180N or The operating force required to achieve a braking force of at least 700N, whichever is less. However, if the wheels are locked, any possible brake overloading is activated, or the brake levers are in contact with the handlebars, no additional operating force is applied. For each operating force, three tests shall be performed within 1 min. Allow the brakes to cool down for 1 min before applying the next operating force;

[0041] B. For reverse brakes, apply a vertical force sufficient to prevent the tires from slipping on the rollers on the bicycle. After accelerating the driving mechanism to the specified speed, apply...

Embodiment 2

[0044] Example 2, such as Figure 1-8 As shown, when performing the wet braking performance test, in addition, the water spray system should be started in advance to spray the brake system no less than 5 seconds before braking, and the water should be continuously sprayed until the end of the test period. : Fix the bicycle on a special machine and increase the counterweight, drive the bicycle to the specified speed, apply the operating force on the brake handle or pedal until the operating force can make the braking force reach 200N±10%, and maintain this force At least 2.5s and record, repeat this procedure of the above-mentioned measured operating force ± 5% 10 times, or more times if necessary, until the average braking force of any one of the last 3 tests and the average braking force of the 3 tests The deviation does not exceed ±10%.

[0045] Working principle: Connect the device to the power supply before use, firstly control the two sets of electric lifting rods 3 to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com