Novel steamed corn bread production machine

A technology of wobow head and production machine, applied in the field of new wow head production machine, can solve the problems of low production efficiency, waste of manpower and material resources, easy pollution of wow head, and achieve the effect of improving production efficiency and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

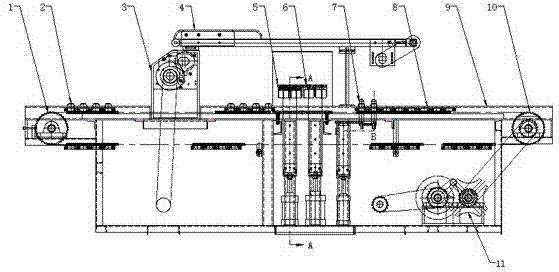

[0009] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it consists of a driven sprocket 1, a molding die 2, a pressure roller assembly 3, an inlet conveying assembly 4, a pre-press forming assembly 5, a cutter assembly 6, an ejection assembly 7, and a crawler belt The plate assembly 8, the frame 9 and the driving sprocket 10 are composed, the driving sprocket 10 is arranged under the front end of the frame 9, the driven sprocket 1 is arranged under the rear end, and the top of the frame 9 is sequentially arranged from the rear end to the front end A molding die 2, a pressure roller assembly 3, a pre-press molding assembly 5, a cutter assembly 6, an ejection assembly 7, and a track shoe assembly 8 are provided, and the surface feeding assembly 4 is connected above the molding die 2, and the drive sprocket 10 and The sheave assembly 11 is connected.

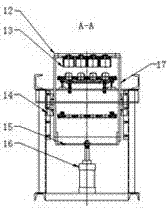

[0010] The pre-compression molding assembly is made up of cutter connecting plate 12, d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap