Joint injector

A joint oil injection and oil injection rod technology, which is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problem of affecting the sealing performance of the cleanliness of the vehicle's oil circuit system, reducing the service life of the automotive power system, and oil mixing in the sealing ring Uneven problems, to achieve the effect of improving fuel injection efficiency and quality, uniform fuel injection effect, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

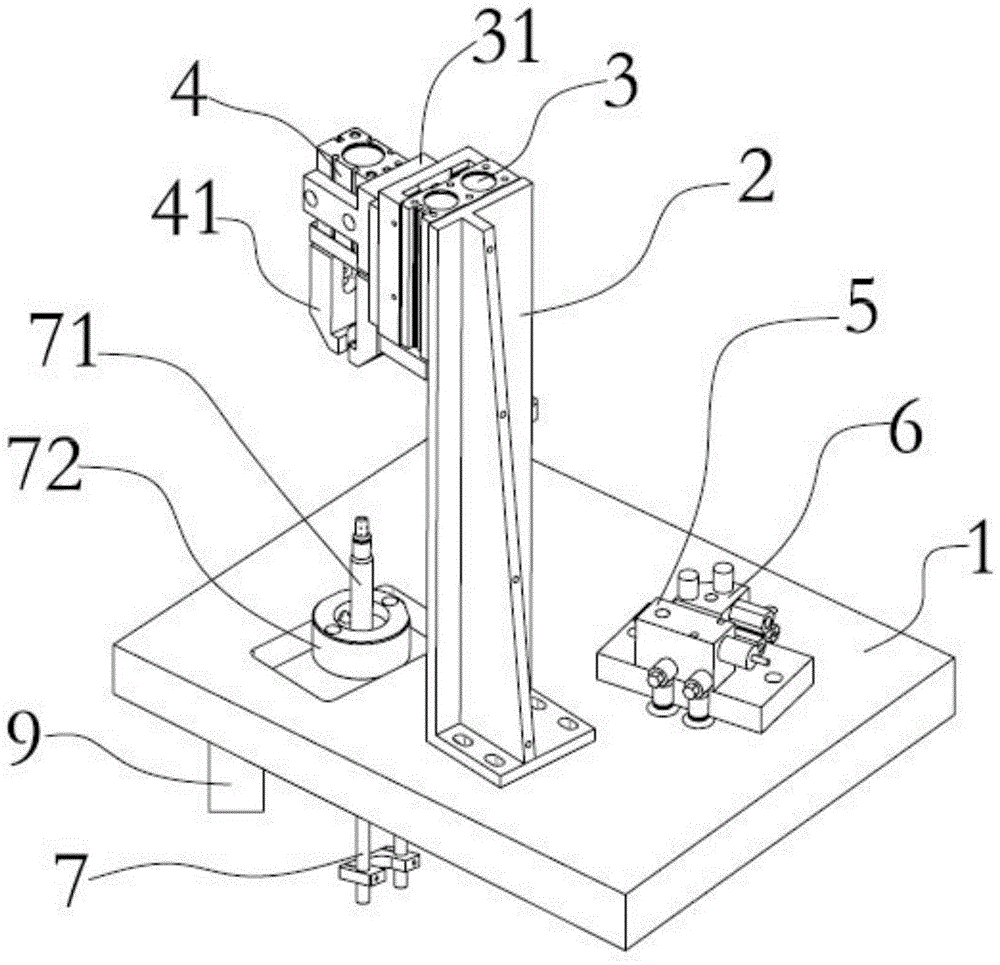

[0015] Such as figure 1 As shown, the present invention is made up of base plate 1 etc., is provided with support base 2 vertically on the upper surface of described base plate 1, is provided with cylinder 3 on one side of described support base 2, is provided with on described cylinder 3 A fixed block 31, the fixed block 31 is provided with a jaw cylinder 4, the lower end of the jaw cylinder 4 is provided with a jaw 41, and a through hole is provided on the bottom plate 1 at the corresponding position directly below the jaw 41 .

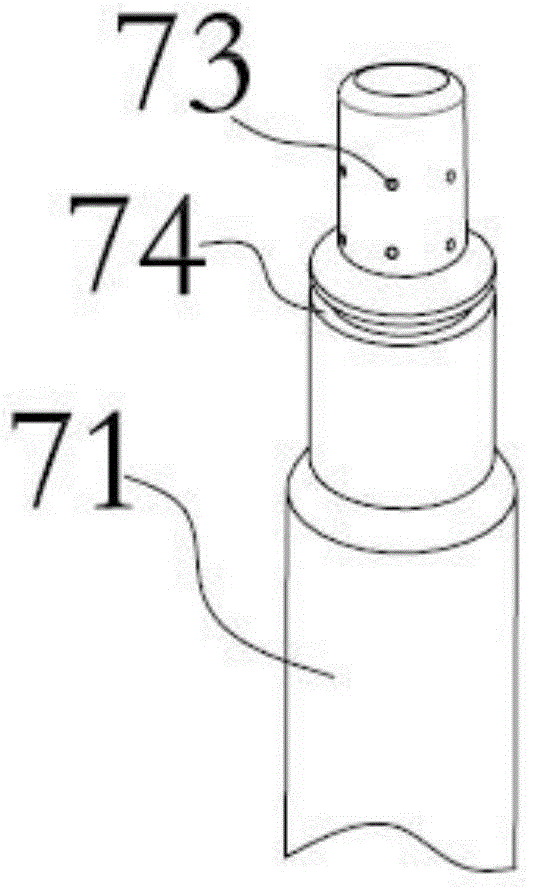

[0016] Such as figure 1 and figure 2 As shown, the position of the lower plate of the base plate 1 facing the through hole is fixed with a double-rod cylinder 7, and the output end of the double-rod cylinder 7 is provided with an upwardly protruding oil spray rod 71, and the oil spray rod 71 Pass through the through hole upwards; between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com