Steam mist device and its flow control method for artificial pollution laboratory of high voltage equipment

A technology of high-voltage equipment and artificial pollution, applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve problems such as high temperature, remote control, and large dispersion of pollution flashover voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

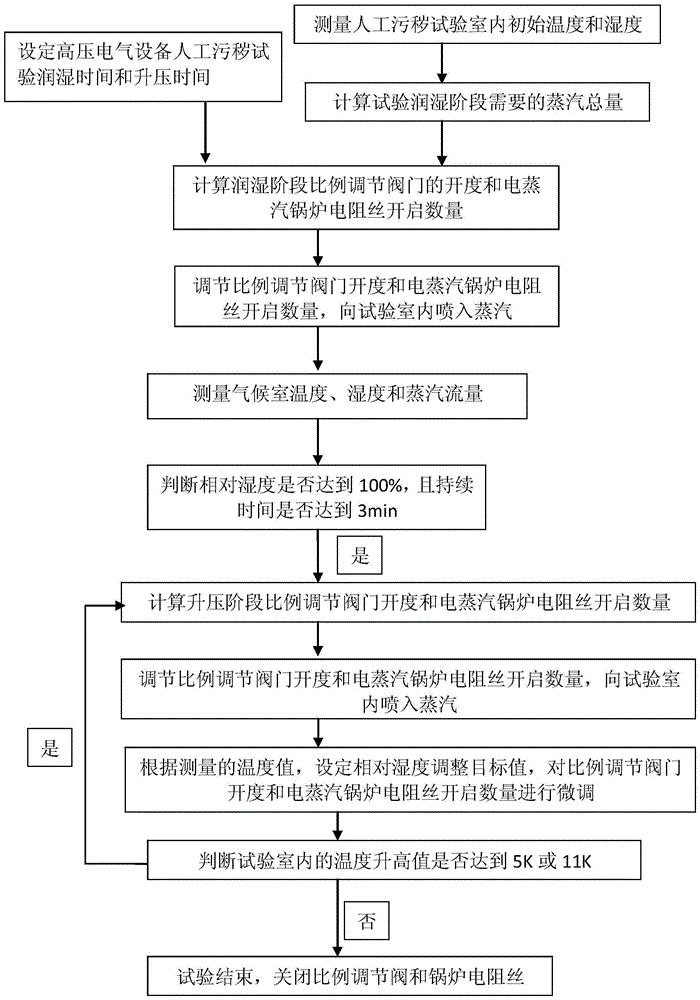

Method used

Image

Examples

Embodiment 1

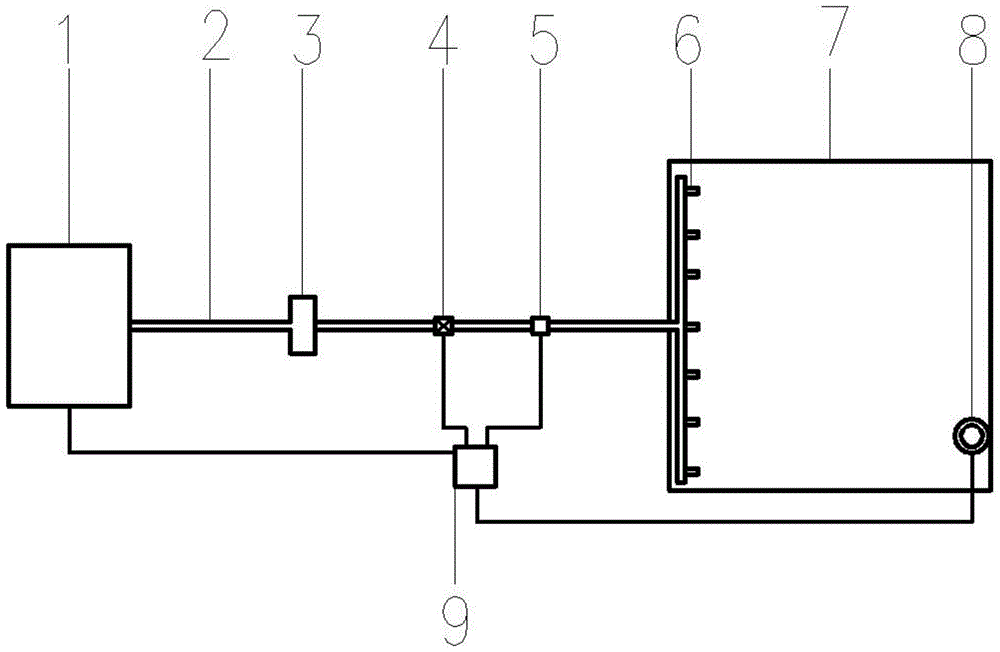

[0089] The electric steam boiler 1 is produced by Shanghai Yannuo Boiler Manufacturing Co., Ltd., the model is WDR2.3-1.3, and the evaporation capacity is 2.3t / h; the steam pipe 2 is made of commercially available ordinary seamless steel pipes, and the pipe diameter is Φ100mm; Cylinder 3 is produced by Yancheng Gongchuang Electric Heating Equipment Co., Ltd., the model is SUB-C25, and the maximum working pressure is 2.5MPa; the proportional control valve 4 is Q941F-16C electric intelligent proportional control valve produced by Shanghai Jiangsen Valve Manufacturing Co., Ltd. , the maximum working pressure is 4MPa; the steam flowmeter 5 adopts the LUGB-24 vortex flowmeter produced by Guangzhou Nanyi Flowmeter Co., Ltd., which can automatically compensate for pressure and temperature; the steam outlet 6 adopts commercially available ordinary seamless steel pipes Processed, the pipe diameter is Φ10mm; the high-voltage electrical equipment artificial pollution laboratory 7 adopts s...

Embodiment 2

[0102] (1) Use a thermo-hygrometer to measure the initial temperature of the artificial pollution laboratory at 12°C; set the wetting time for the artificial pollution test of high-voltage electrical equipment to 10 minutes and the boosting time to 60 minutes for the automatic steam flow controller;

[0103] (2) The steam flow automatic controller is based on the temperature tested in step (1) and the volume of the artificial climate chamber is 6037m 3 , the total amount of steam required by preliminary calculation is 200.37kg;

[0104] (3) The steam flow automatic controller calculates the steam flow in the steam wetting stage as 1202.2kg / h according to the total amount of steam initially calculated in step (2) and the wetting time and boosting time set in step (1). Adjust the opening of the valve to 80%, and put in 43 groups of electric steam boiler resistance wires;

[0105] Step (4) According to the steam flow calculated in step (3), the steam flow automatic controller au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com