A fully automatic leveling device and method for a 3D printer tray

A technology of 3D printer and leveling device, which is applied in processing and manufacturing, liquid material additive processing, additive processing, etc. It can solve the problems that the XY axis cannot be kept level, and the tray bearing surface cannot be kept level, so as to ensure the printing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

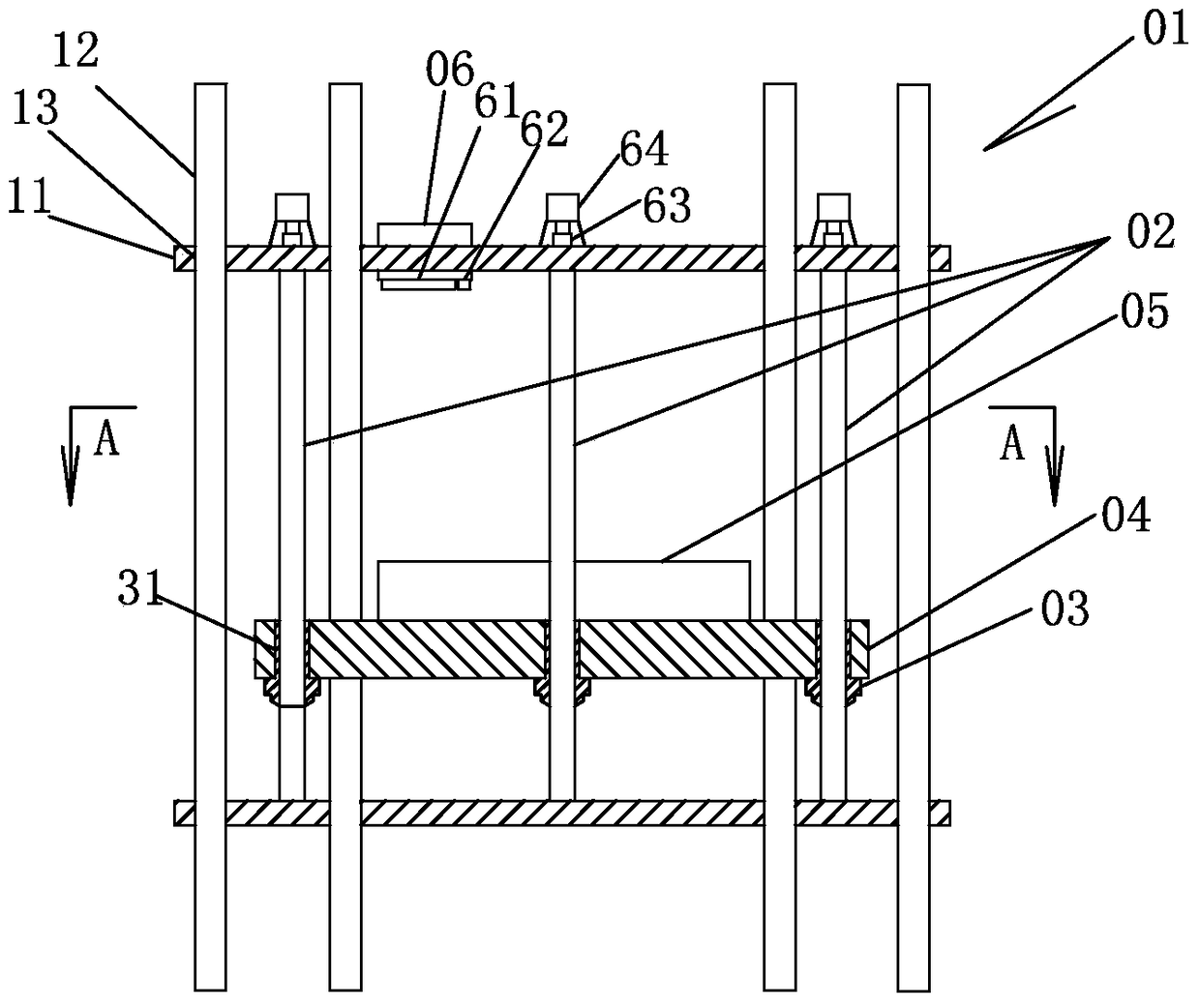

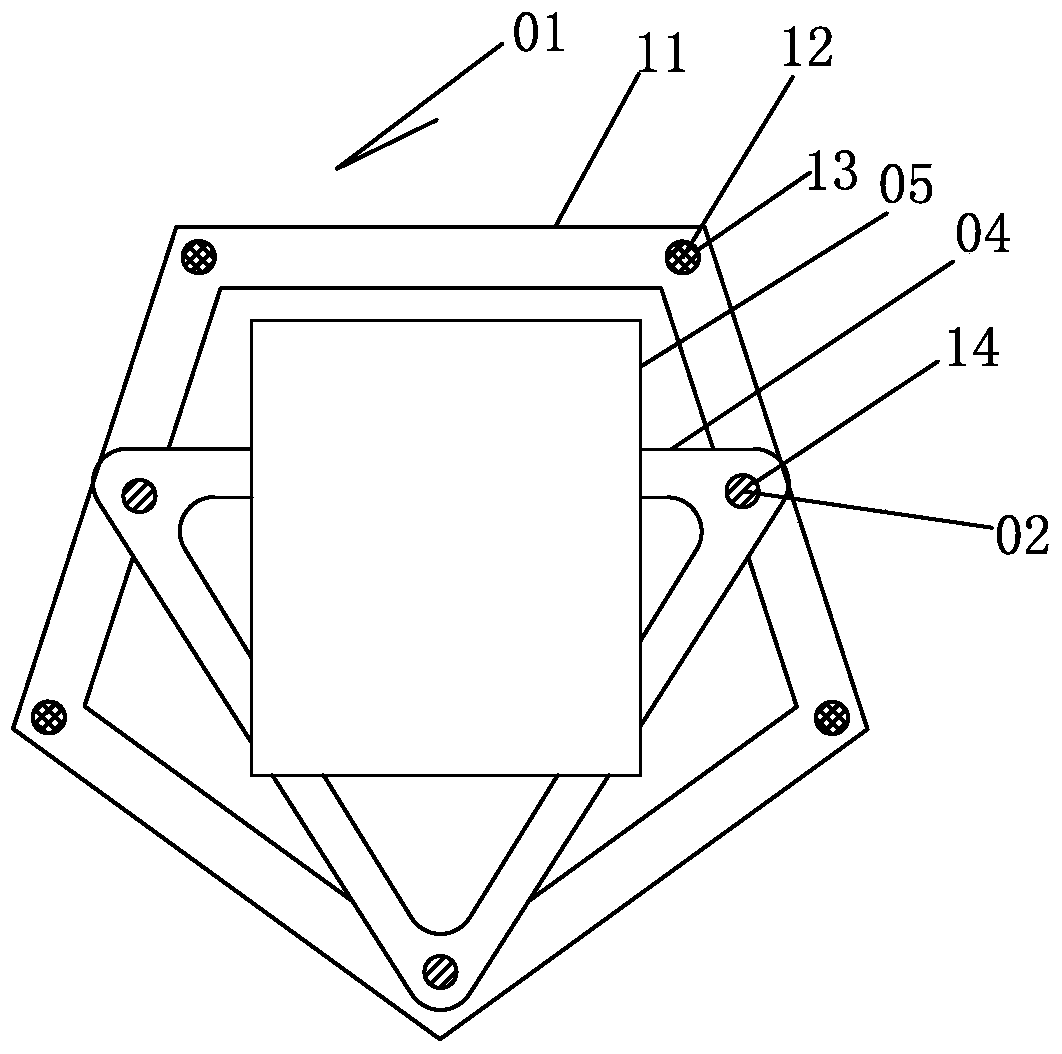

[0026] Such as figure 1 and figure 2 As shown, the fully automatic leveling device for the 3D printer tray in this embodiment includes three lead screws 02 arranged on the fixed frame 01 and parallel to the Z axis. The lead screw nut 03 of each lead screw is embedded in the support frame 04, and the support frame 04 Upper fixed tray 05;

[0027] Fixing frame 01 comprises the parallel horizontal fixing ring 11 of upper floor and lower floor, vertical four columns 12, and horizontal fixing ring 11, and the inner and outer contours of horizontal fixing ring 11 are similar regular pentagons. The second, third, and fourth apex positions are opened with a column through hole 13, and the lead screw through hole 14 is opened at the fifth apex position, the midpoint position of the first and second apexes, and the midpoint position of the third and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com