A fully automatic frying pan

A fully automatic frying pan technology, applied in heating devices, cooking utensils, household utensils, etc., can solve the problems of difficult to ensure the quality of frying, incomplete color and aroma of materials, and difficult temperature control, etc., to shorten the frying time and maintain The effect of color, fragrance and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

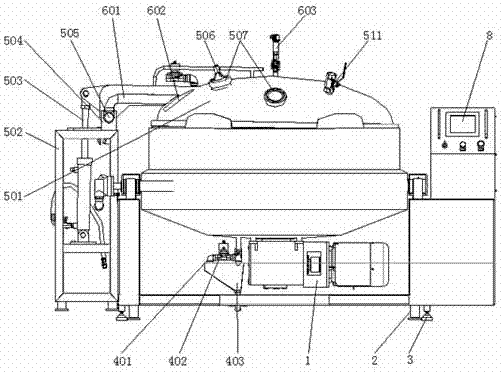

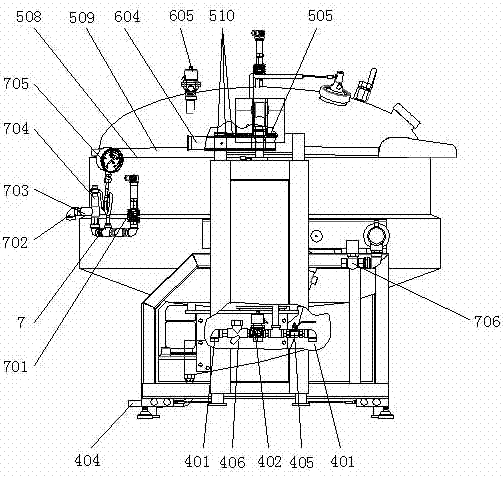

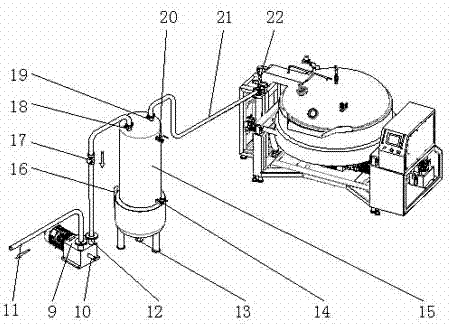

[0032] Such as Figure 1~3 As shown, a fully automatic wok includes a reversible wok main body, a geared motor 1 and a fixed support foot 2 at the bottom of the wok, a stirring device is installed inside the wok main body, and a heating device is installed on the wok main body. The main body of the wok is equipped with an automatic flip cover device 5, a condensed water collection device 4 is arranged under the main body of the wok, a vacuum control device 6 and an auxiliary material feed valve 511 are arranged on the cover device 5, and the fryer One side of the main body of the wok is provided with a pressure control device 7, the pressure control device communicates with the internal jacket of the wok main body through a pipeline, an automatic control center 8 is arranged next to the main body of the wok, and the bottom of the main body of the wok is provided with The weighing sensor 3 for material weight measurement, the pot cover device 5 , the vacuum control device 6 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com