A device for cleaning and collecting iron filings

A technology for collecting device and iron filings, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of clogging of iron filings, collection of iron filings, etc., and achieve the effect of easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

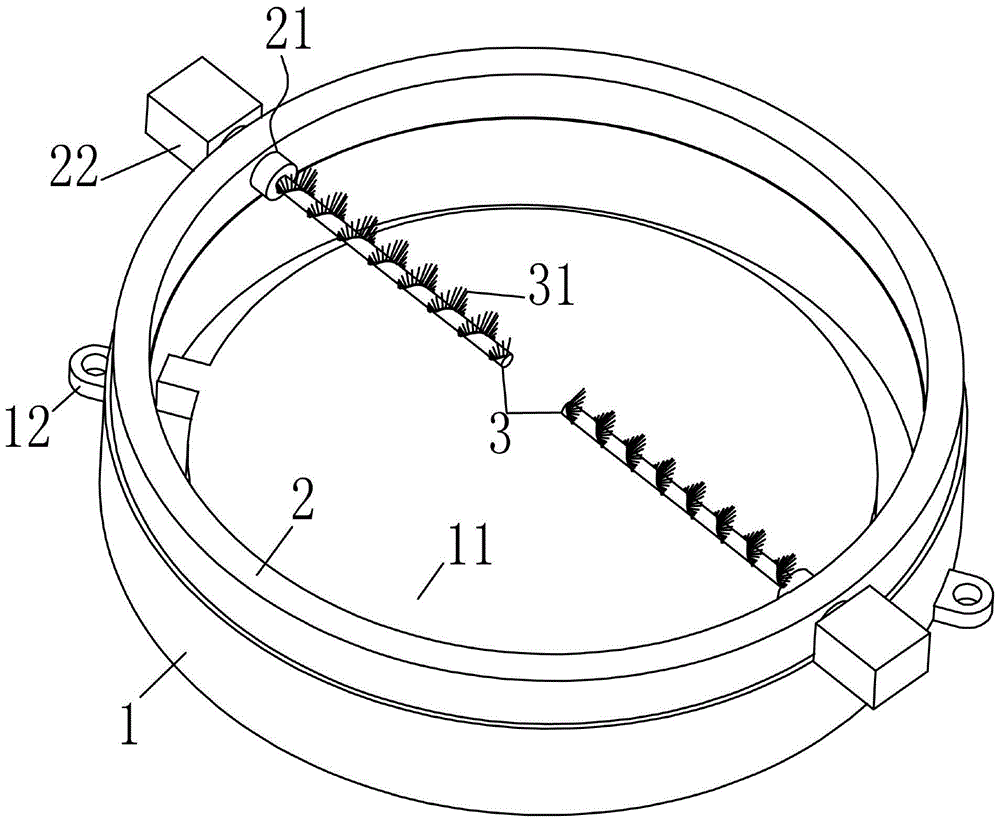

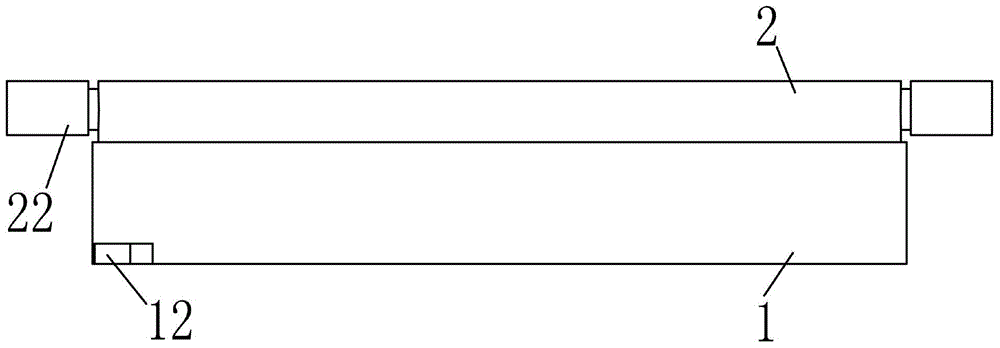

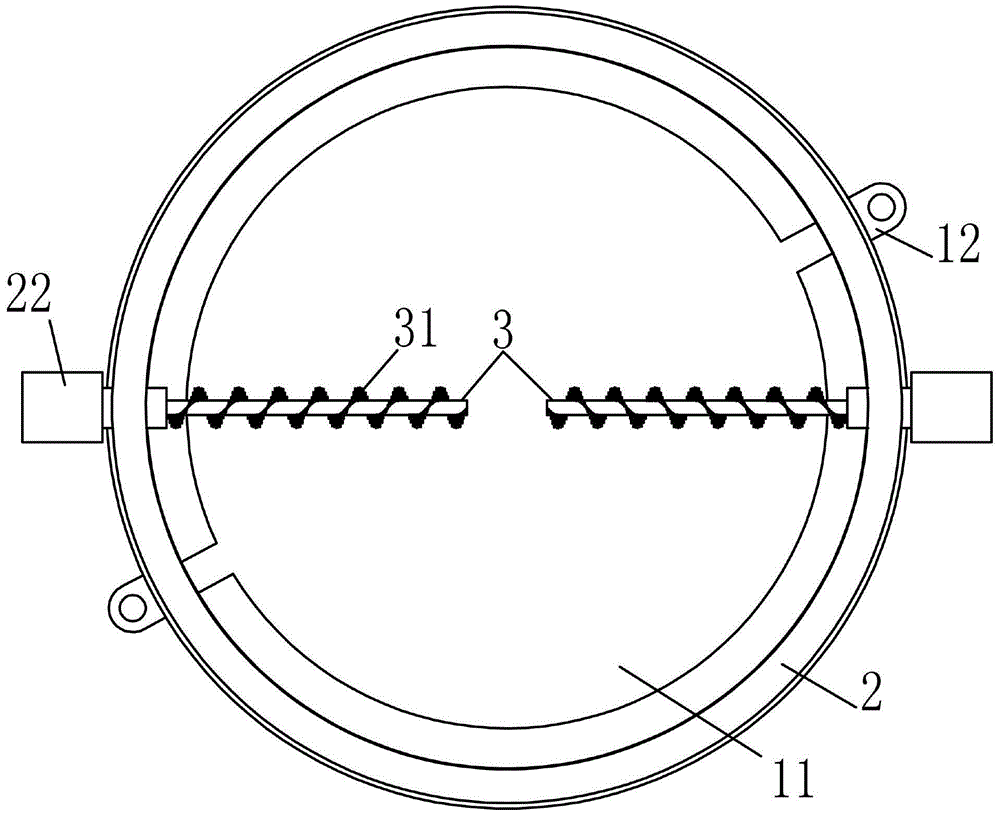

[0015] Such as figure 1 , figure 2 , image 3 As shown, a chip cleaning and collecting device in this embodiment includes a base plate 1, a rotating plate 2 and a chip brush 3, the base plate 1 is located below the rotating plate 2, and the base plate 1 and the rotating plate 2 Through the bearing connection, the axis of the base plate 1 is aligned with the axis of the rotary plate 2, so that the rotary plate 2 can rotate around the base plate 1. The base plate 1 is in the shape of a ring, and a disc 11 is arranged at the middle and lower part of the base plate 1. And there is a gap between the disc 11 and the base disc 1 for accommodating iron filings, and connecting ears 12 are provided on both sides of the bottom of the base disc 1; Symmetrical through holes 21; the number of the chip brushes 3 is two, one end of the chip brushes 3 is connected to the motor 22 through the through holes 21, and the other end is suspended above the disc 11, and the chip brushes 3 are provi...

Embodiment 2

[0017] The iron filings cleaning and collecting device of this embodiment has the same basic structure as that of the first embodiment, except that the distance between the two iron filings brushes 3 is twice the diameter of the drill bit.

[0018] When the iron filings cleaning and collecting device of Embodiment 1-2 is in use, driven by the motor, the rotating disk 2 rotates relative to the base plate 1, and at the same time the iron filings brush 3 rotates clockwise, and the iron filings generated by the drilling machine fall to the On the disc 11, under the rotation of the iron filings brush 3, it is swept into the gap between the disc 11 and the base plate 1, so that the iron filings are stored in the gap, which can prevent the iron filings from flying everywhere, and also It can collect and utilize iron filings in a concentrated manner.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap