Dispensing screw

A screw and glue dispensing technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of inconsistent bite force, unreachable, unsatisfactory glue dispensing methods, etc., to achieve strong bite force and satisfy the effect of super vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

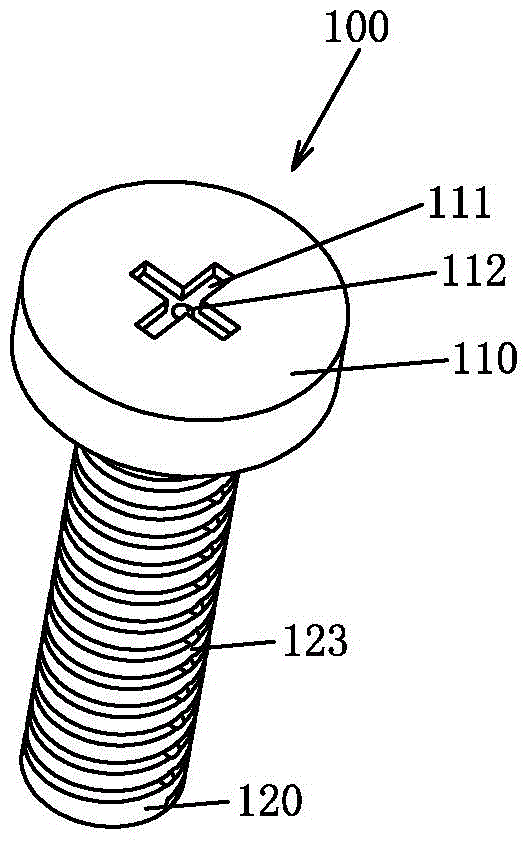

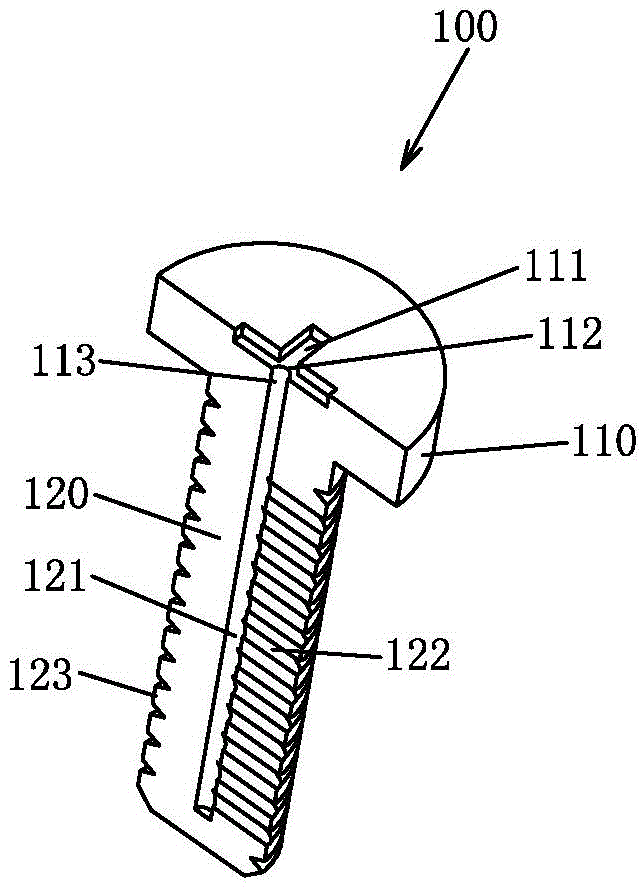

[0018] For this purpose, please refer to the figure 1 and figure 2 It is shown that the dispensing screw 100 provided by the present invention is applied to a nut locked in an implanted electronic product, and the dispensing screw 100 includes:

[0019] Screw cap 110, its upper end surface is provided with a concave groove 111, the interior of described concave groove 111 is provided with a little glue port 112, and described screw cap 110 is provided with a little glue flow channel 113 downwards along described glue dispensing port 112, and described concave Groove 111 is used for twisting this dispensing screw 100;

[0020] Screw body 120, the main body of which is cylindrical, the upper end of the screw body 120 is connected to the lower end surface of the screw cap 110, a vertical flow channel 121 is arranged insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com