A Comprehensive Judgment Method for Shafting Faults of Space Moving Parts

A technology for moving parts and faults, applied in the field of comprehensive evaluation of shafting faults of space moving parts, can solve the problems of slow response to current faults, low sensitivity, difficult monitoring, etc., to avoid missed fault judgments, improve durability, and improve reliability. Effects of Sexuality and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

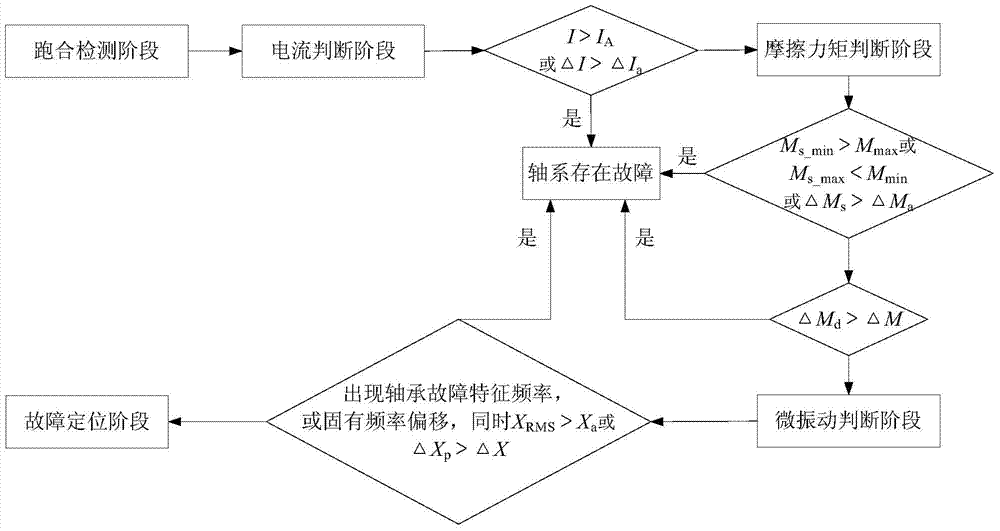

[0047] The basic idea of the present invention is to provide a comprehensive evaluation method for the shafting fault of the space movable part. For the shafting fault of the space movable part, after the shafting completes the run-in detection stage, the current judgment stage, the friction torque judgment stage, the Micro-vibration Judgment Stage Three judgment stages evaluate the state of the shafting system. Finally, through the fault location stage, the fault location of the shafting system can be realized without dismantling the shafting system.

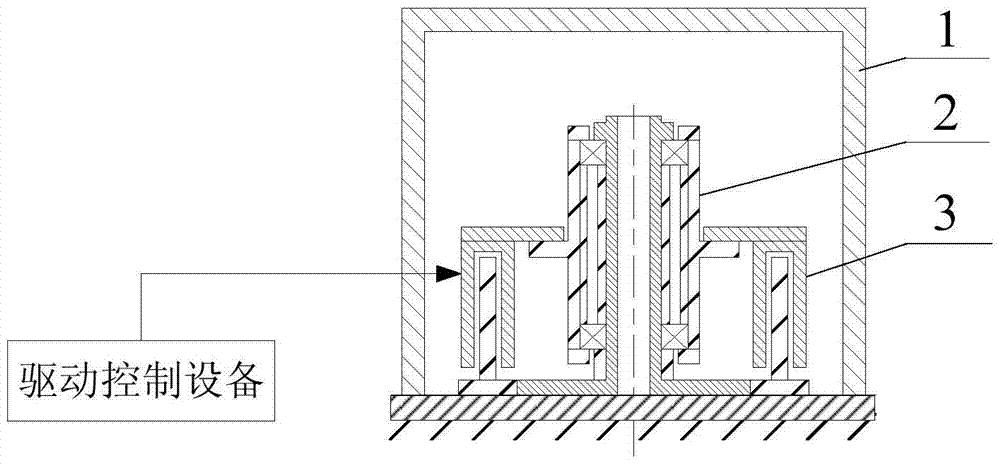

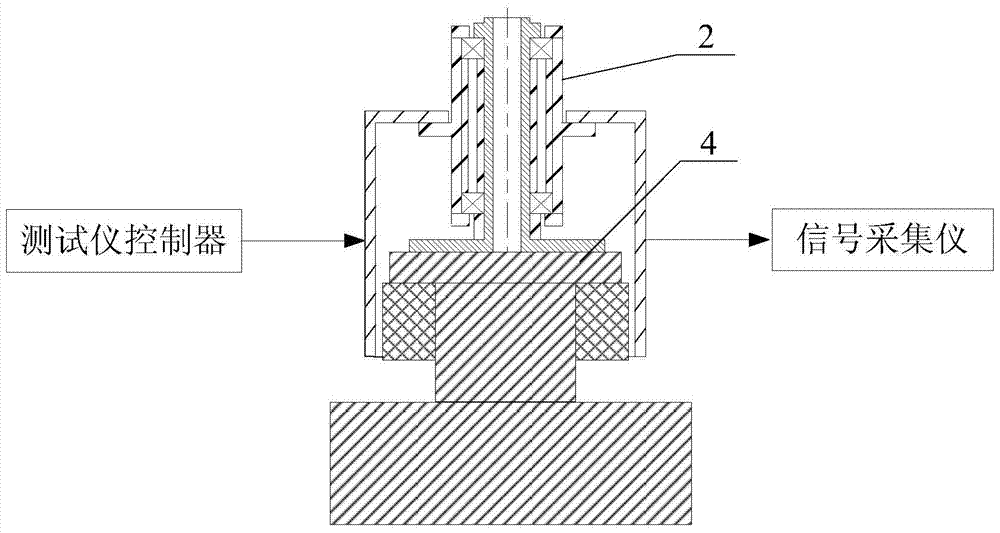

[0048] Such as Figure 10 As shown, the shaft system to be tested includes a pair of angular contact ball bearings 7, a main shaft 8, a housing 10, an outer loading sleeve 11, an inner loading sleeve 12, an upper clamping nut 9, a lower clamping nut 13 and a base . The base is perpendicular to the main shaft and is integrally processed with the main shaft; a pair of angular contact ball bearings 7 is installed between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com