Bridge crane conical motor

A technology of conical motors and motor shafts, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of high startup frequency, aggravated bearing wear, and short working cycle, so as to increase the average safe service life and improve safe use The effect of life and maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

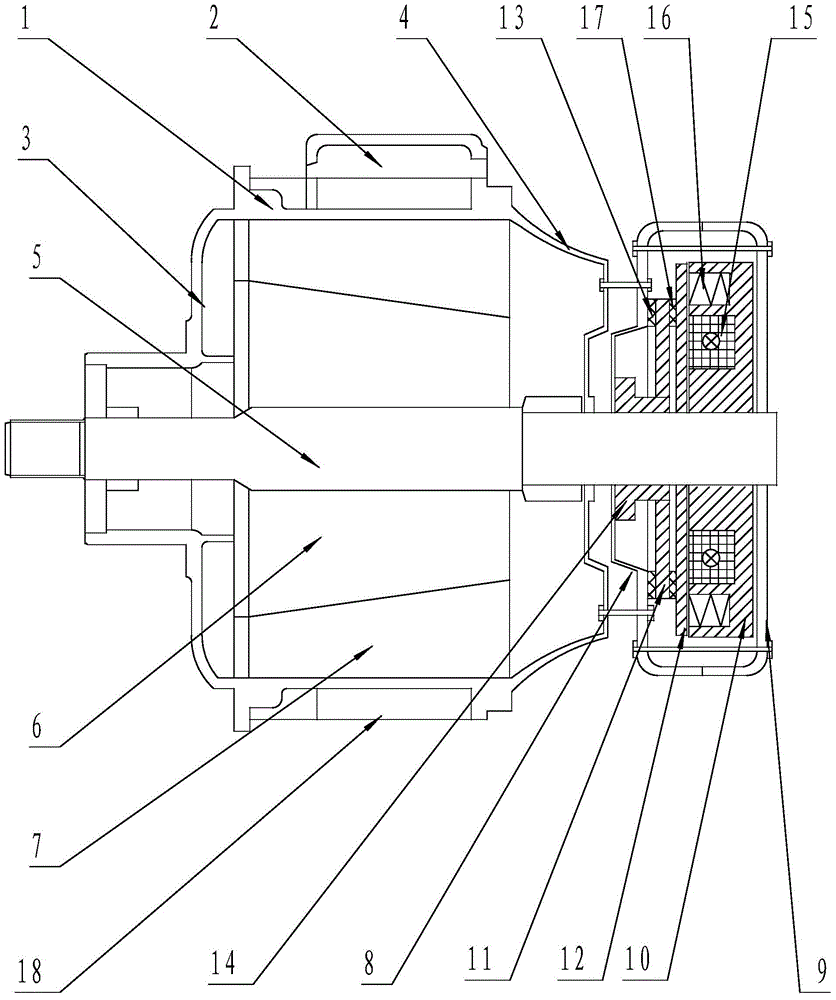

[0015] Such as figure 1 As shown, a driving cone motor includes a housing 1, a front end cover 3, and a rear end cover 4. A junction box 2 is arranged on the outer wall of the housing 1, and the front end cover 3 is arranged on the left end of the housing 1, so that The rear end cover 4 is arranged on the right end of the housing 1, and is characterized in that it also includes a motor shaft 5, on which a conical rotor 6 is arranged, and the outer ring of the conical rotor 6 is provided with a The rotor 6 is matched with the stator 7, and the motor shaft 5 is rotationally connected with the front end cover 3 and the rear end cover 4 using bearings respectively; the motor shaft 5 also has a part extending from the rear end cover 4, and the motor shaft 5 extends The driving cone motor braking device is installed on the part of the rear end cover 4;

[0016] The driving cone motor braking device is a driving cone motor brake, and the driving cone motor brake includes a front bra...

Embodiment 2

[0018] Such as figure 1 As shown, a driving cone motor includes a housing 1, a front end cover 3, and a rear end cover 4. A junction box 2 is arranged on the outer wall of the housing 1, and the front end cover 3 is arranged on the left end of the housing 1, so that The rear end cover 4 is arranged on the right end of the housing 1, and is characterized in that it also includes a motor shaft 5, on which a conical rotor 6 is arranged, and the outer ring of the conical rotor 6 is provided with a The rotor 6 is matched with the stator 7, and the motor shaft 5 is rotationally connected with the front end cover 3 and the rear end cover 4 using bearings respectively; the motor shaft 5 also has a part extending from the rear end cover 4, and the motor shaft 5 extends The driving cone motor braking device is installed on the part of the rear end cover 4;

[0019] The driving cone motor braking device is a driving cone motor brake, and the driving cone motor brake includes a front bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com