Permanent magnet embedded rotor for direct current brushless motor

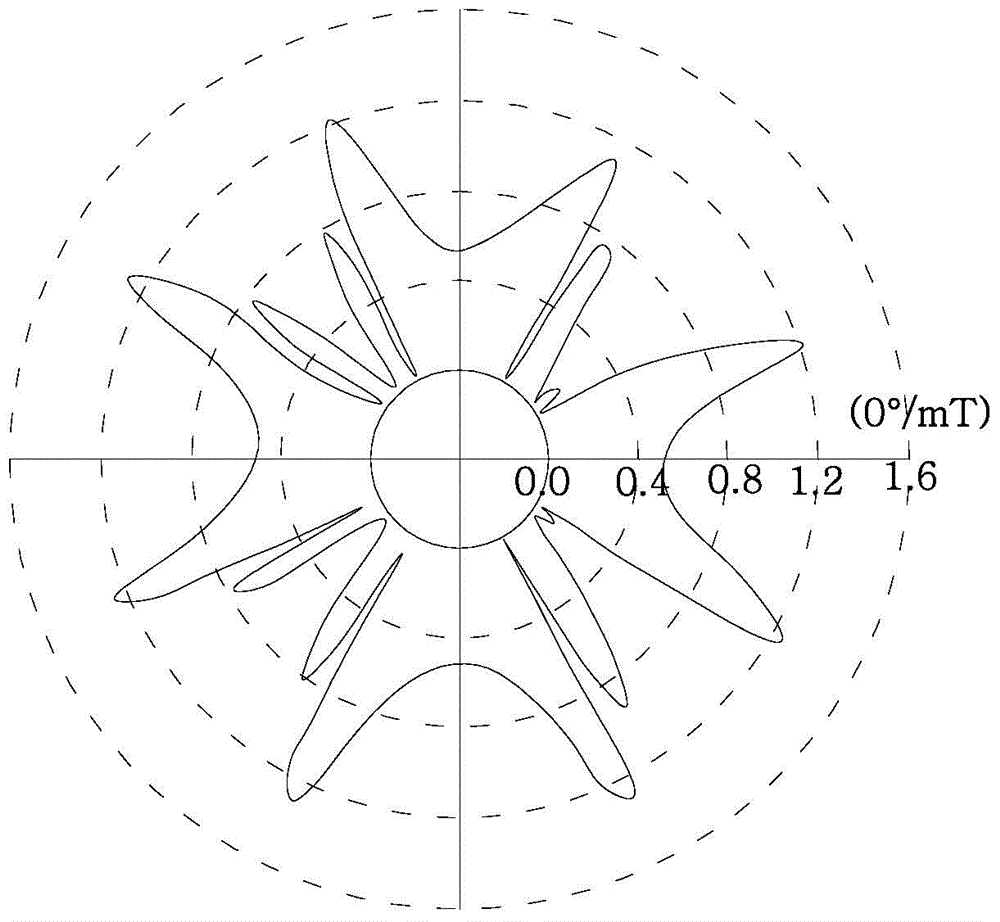

A brushless DC motor and permanent magnet technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the increase in motor output torque fluctuations , Hall signal jitter, drive waveform distortion and other problems, to achieve the effect of reducing output torque fluctuation, increasing power density and avoiding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

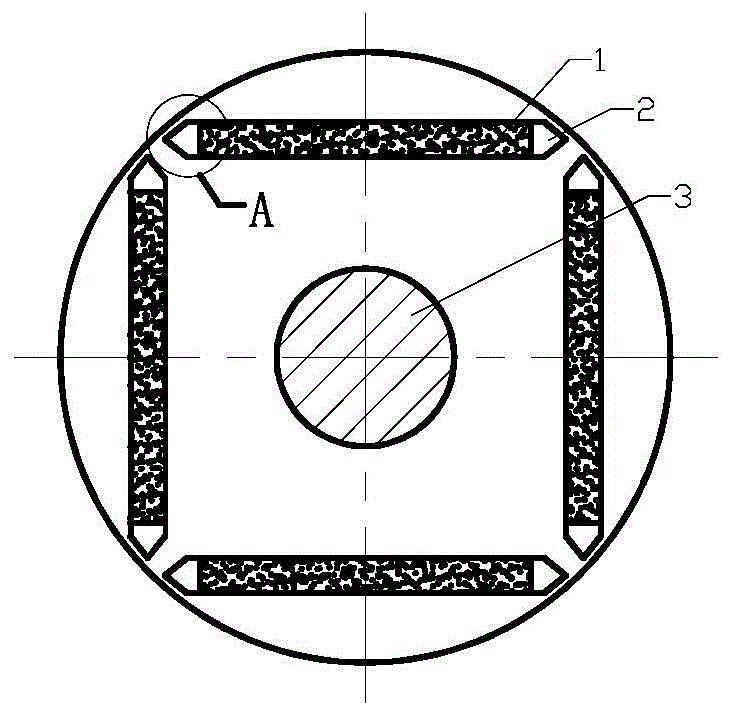

[0046] see Figure 10-11 , a permanent magnet embedded rotor for a brushless DC motor, comprising:

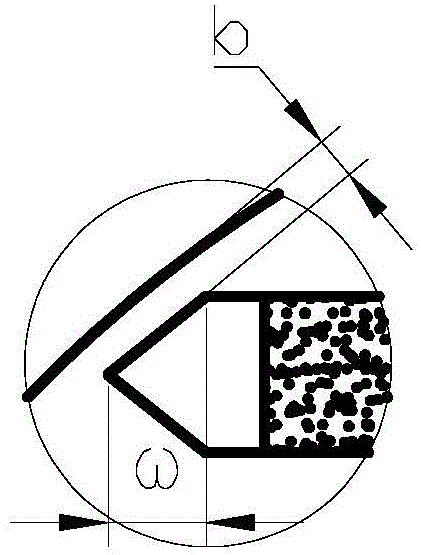

[0047] The cylindrical rotor core A formed by laminating the rotor punches has p pairs of strip-shaped permanent magnet slots C and 2p heat dissipation through holes B; wherein, the p pairs of permanent magnet slots C and the 2p heat dissipation through holes B are arranged inside the rotor core A along the direction of the central axis of the rotor core A, and are evenly spaced around the central axis of the rotor core A; each of the heat dissipation through holes B is located between two permanent magnet slots C, p is an integer greater than or equal to 1; and

[0048] P pairs of strip-shaped permanent magnets D are fixedly arranged in the permanent magnet groove C, wherein the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com