A low-temperature phase-change memory alloy tissue stapler

A technology of memory alloy and low-temperature phase change, which is applied in the fields of surgical instruments, medical science, and pharmaceutical formulations. It can solve the problems of skin tissue contusion, affecting suturing effect, and affecting wound healing time, etc., and achieves high production efficiency, smooth operation process, The effect of meeting the needs of clinical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

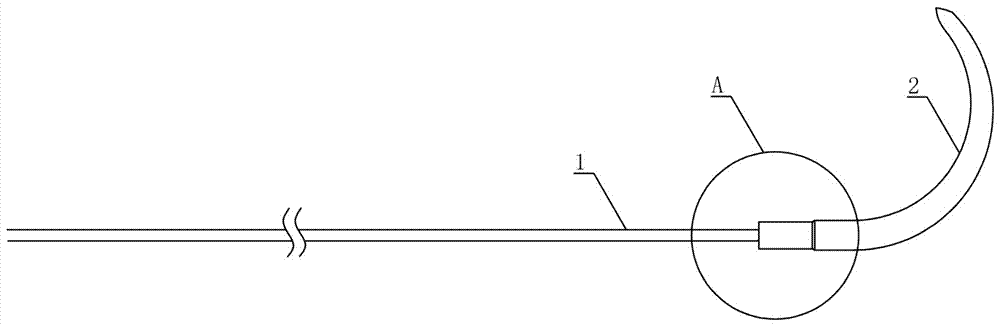

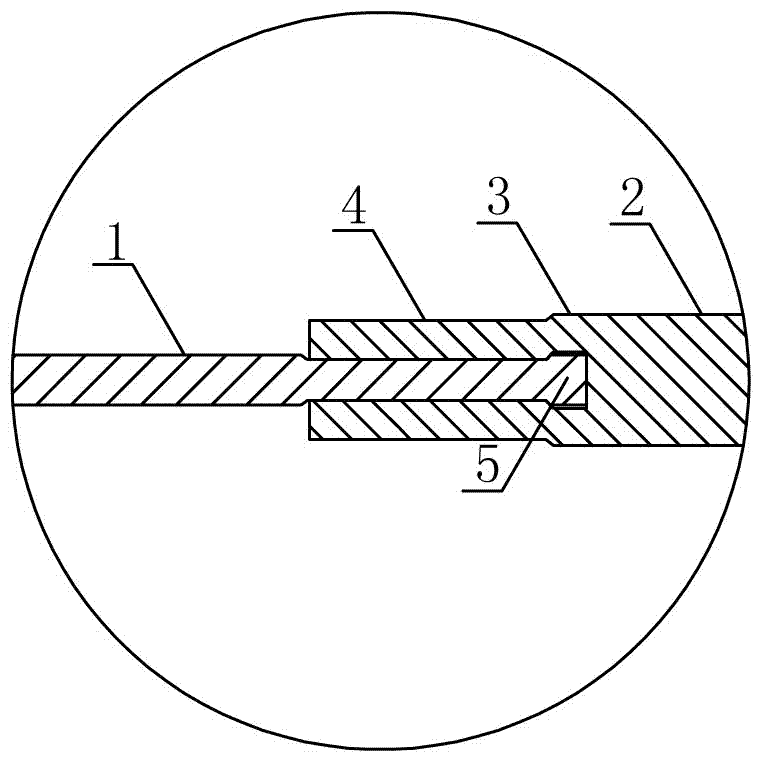

[0025] A low-temperature phase-change memory alloy tissue stapler, including a medical suture 1 made of titanium-nickel memory alloy and a layer of silver ion plating material with a thickness of 0.1-1 μm deposited on the surface, and one end of the suture 1 is connected to a 3 / 8-arc non-injury medical suture needle 2, the needle type is a round needle, the non-puncture end of non-injury medical suture needle 2 adopts 3 laser drilling methods to form blind holes, the hole depth is 1.5mm, and different suture needles are connected to meet Surgical suturing needs of different parts. The phase transition temperature of the suture was set at 24°C, and the memorized shape was a straight line.

Embodiment 2

[0027] A low-temperature phase-change memory alloy tissue stapler, including a medical suture 1 made of a titanium-nickel memory alloy and a silver ion plating layer with a thickness of 0.1 to 1 μm deposited on the surface of the alloy. One end of the suture 1 is connected to a 3 made of stainless steel. / 8 degree arc non-invasive medical suture needle 2, the needle type is triangular needle, the non-puncture end of non-invasive medical suture needle 2 adopts 3 laser drilling methods to form a blind hole, the hole depth is 1.8mm, by connecting different suture needles, To meet the suturing needs of different parts. The phase transition temperature of the suture was set at 25°C, and the memorized shape was a straight line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com