A spiral nozzle that can be used in automatic fire extinguishers

A fire extinguisher and spiral technology, which is applied in the field of fire fighting equipment, can solve the problems of short injection time, rapid injection, and unsatisfactory fire extinguishing effect, and achieve the effect of wide range and long injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

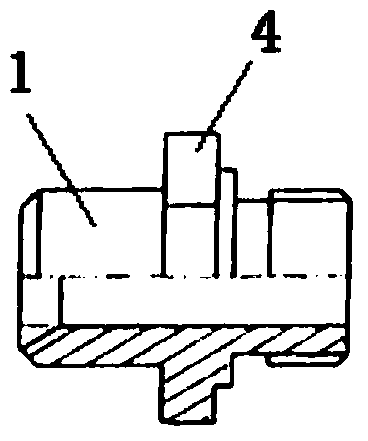

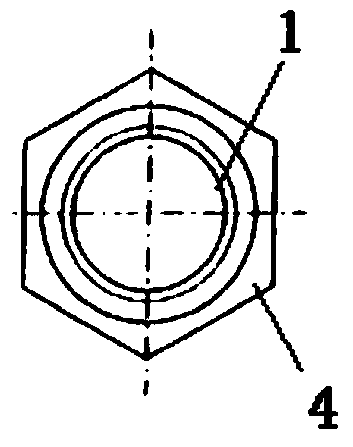

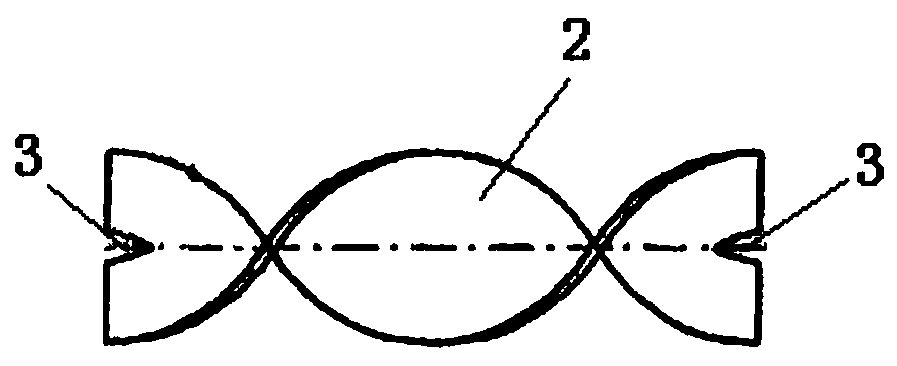

[0020] Such as figure 1 The shown spiral nozzle that can be used in automatic fire extinguishers includes a nozzle 1 and a spiral body 2 disposed inside the nozzle 1. The spiral body 2 is formed by rotating a rectangular sheet with a cutout 3 at each end. The nozzle system of the automatic fire extinguishing system is based on the principle of aerodynamics. When the automatic fire extinguishing system is started, the agent inside the fire extinguishing system will generate a resistance and a tangential force when it passes through the spiral body in the nozzle under the action of pressure. The resistance can prolong the life of the agent. The tangential force can expand the fire extinguishing range of the automatic fire extinguishing system. Finally, the fire extinguishing effect of the automatic fire extinguishing system is increased.

[0021] Such as figure 2 As shown, the nozzle 1 is cylindrical, and a hexagonal snap ring 4 is fixed in the middle of the outside.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com