Rolling device for continuous differential thickness plate

A differential plate and roll technology, applied in the field of continuous differential plate rolling devices, can solve the problems of not having a rolling differential plate production line, affecting the surface quality of stamping parts, and having welds in the transition area, and achieving production organization. Flexible, simple structure, and achieve the effect of profiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

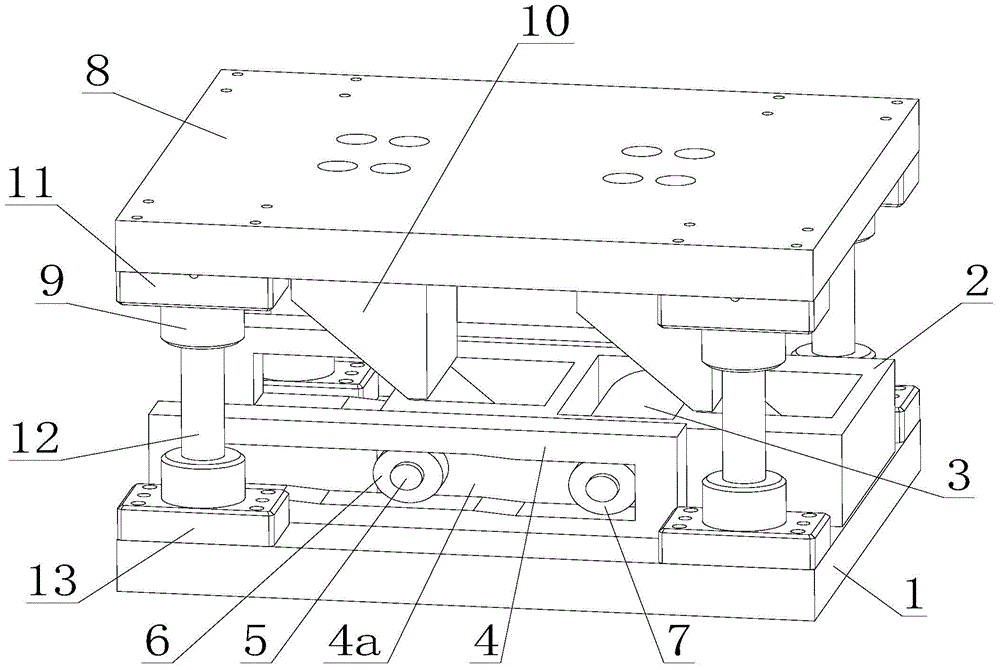

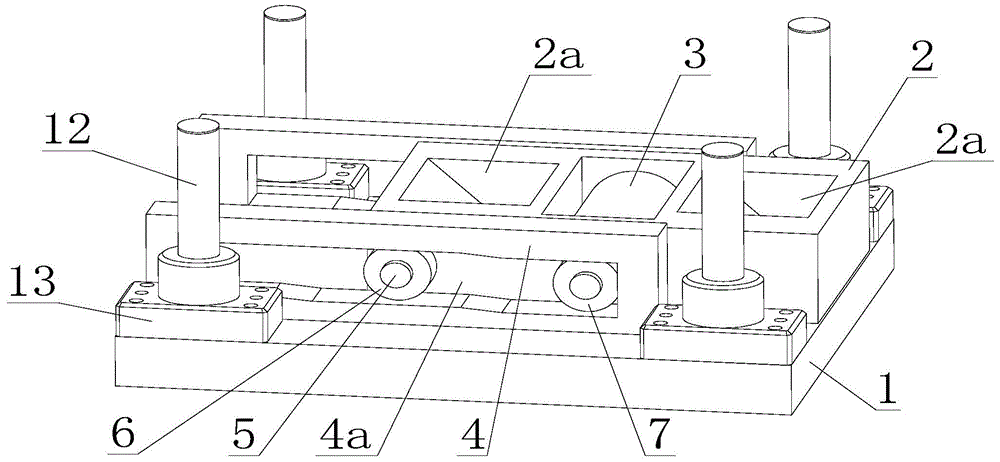

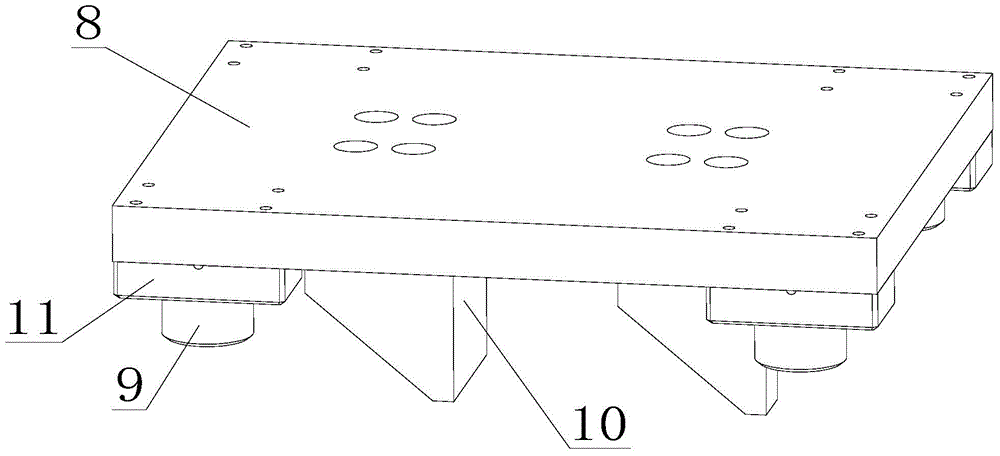

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the connecting structure of the base and the rolling mechanism of the present invention, image 3 It is a schematic diagram of the structure of the upper die as the driving mechanism of the present invention, as shown in the figure: the rolling device of the continuous differential thickness plate in this embodiment includes a base 1, a rolling mechanism slidably arranged on the base 1, for A driving mechanism that drives the rolling mechanism, wherein the base 1 is used to support and place the sheet to be processed, the rolling mechanism is used to roll the sheet, and the driving mechanism is used to drive the rolling mechanism to move laterally along the base 1 . The rolling mechanism includes a slide block 2, a roll 3 and a guide plate 4, the roll 3 is rotatably arranged in the slide block 2, the guide plate 4 is located outside the slide block 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com