A Method for Machining Curved Surface Shafts on a Profile Lathe with a Cutting Compensation Mechanism

A compensation mechanism and a technology for profiling lathes, applied in the field of profiling lathes, can solve the problems of low machining accuracy and short service life, and achieve the effects of reasonable structural design, high degree of automation, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

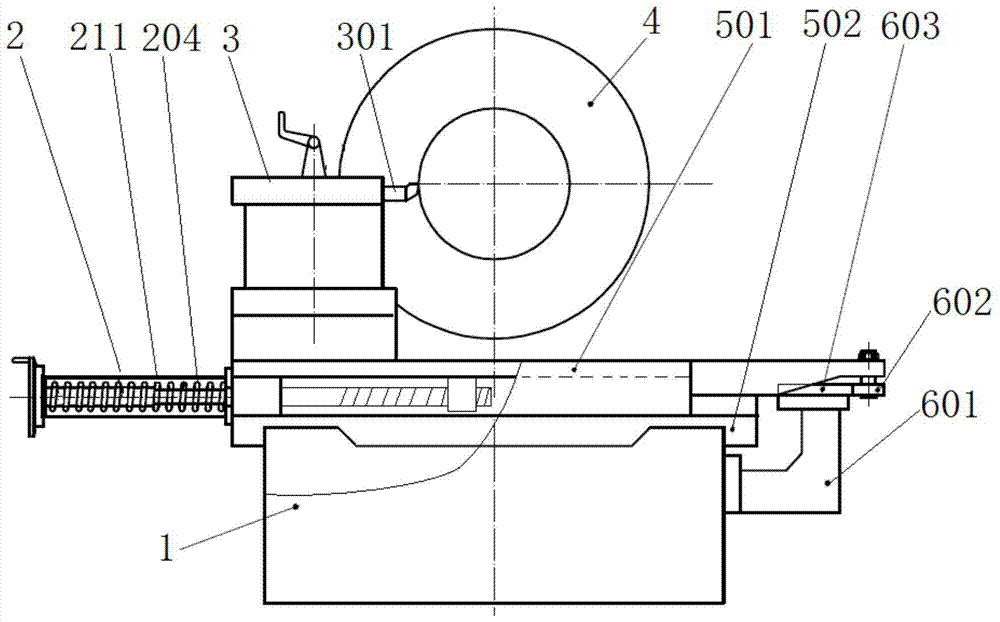

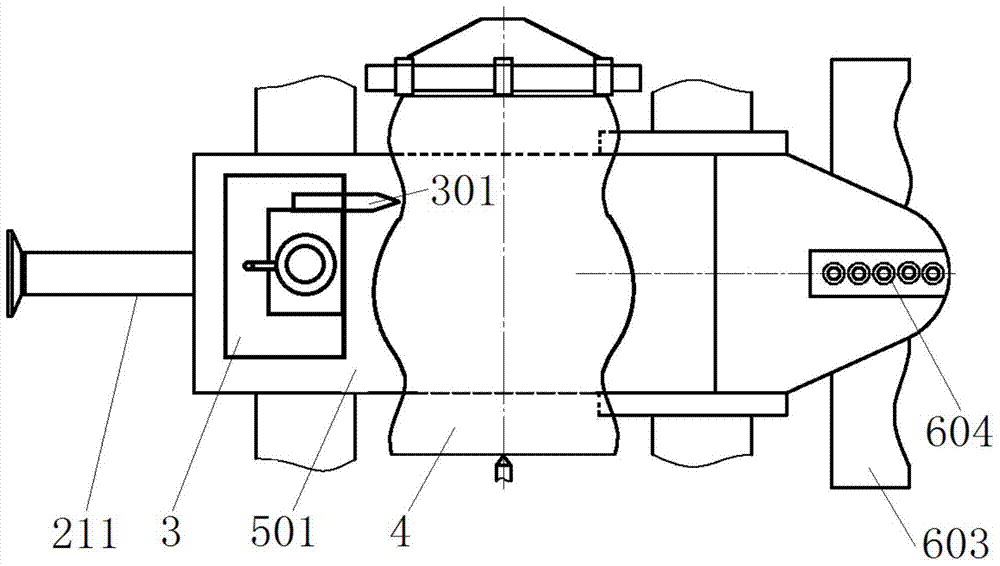

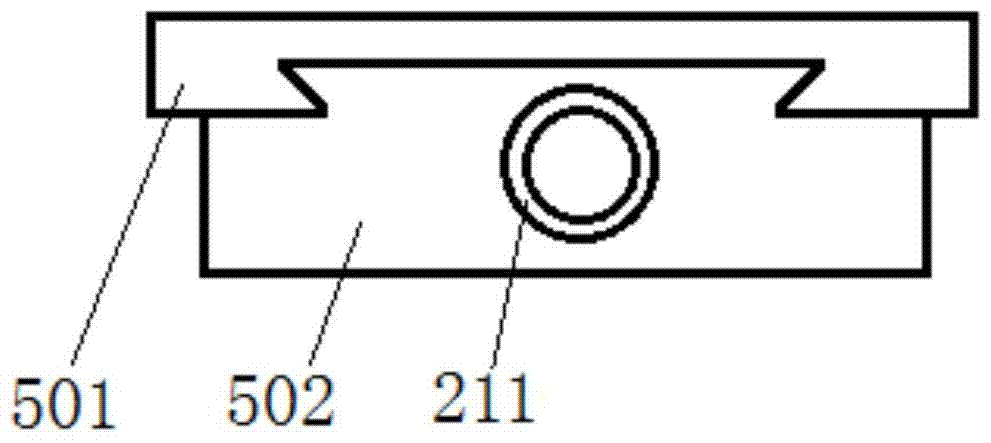

[0043] combine figure 1 and figure 2 , a method for processing a curved surface shaft on a profiling lathe with a cutting compensation mechanism in this embodiment, the profiling lathe used is mainly composed of a lathe body 1, a pull plate 501, a supporting plate 502, a tool holder 3, and a cutting compensation mechanism 2 And profiling mechanism etc. composition. Wherein, the supporting plate 502 and the lathe body 1 are driven by a screw, so that the supporting plate 502 slides longitudinally along the lathe body 1 , that is, moves along the axial direction of the workpiece 4 to be processed. Such as image 3 As shown, a tenon is provided on the supporting plate 502, and the lower part of the pulling plate 501 is a tenon-groove structure. The pulling plate 501 and the supporting plate 502 are slidably connected through the cooperation between the tenon and the tenon, and the pulling plate 501 can slide laterally along the supporting plate 502. . Fixing the knife seat 3...

Embodiment 2

[0054] A method for machining a curved surface shaft with a profiling lathe with a cutting compensation mechanism in this embodiment has the same basic structure as that of Embodiment 1, the difference being that in the outer sleeve groove 205 and the inner sleeve groove 207, the limit The width of the position bar 206 protruding to the linear sliding section is 0.25 times of the diameter of the stop bar 206, the outer groove inclined section 2051 and the inner groove inclined section 2071 are composed of a first inclined section and a second inclined section, the first inclined section and the second inclined section The straight-line sliding section is connected, and the included angle between the first inclined section and the direction of the straight-line sliding section is smaller than the included angle between the second inclined section and the direction of the straight-line sliding section. The purpose of switching the limit rod 206 can also be achieved through the tw...

Embodiment 3

[0056] A method for processing a curved shaft on a profiling lathe with a cutting compensation mechanism in this embodiment has the same basic structure as that of Embodiment 1, except that a dust cover 211 is placed on the outer circumference of the external compression spring 204 to prevent Dust enters between the outer sleeve 203 and the inner sleeve 208 to affect its slidability. A sliding sleeve 210 is arranged on the supporting plate 502, and the sliding sleeve 210 can prevent wear on the shaft rod 202 and ensure its slidability. Since the movement deformation of the external compression spring 204 exceeds 2D / 3, it will be difficult to provide the force required for the concave arc of the profiling surface, so the distance between the engaging section in the outer sleeve groove 205 and the engaging section in the inner sleeve groove 207 It can be set to 2D / 3, and the resistance compensated by the internal compression spring 209 does not exceed the maximum resistance exer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com