Roller blind system for a sliding roof

A technology of roller blinds and rollers, which is applied in the field of roller blind systems and can solve problems such as increased space requirements and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

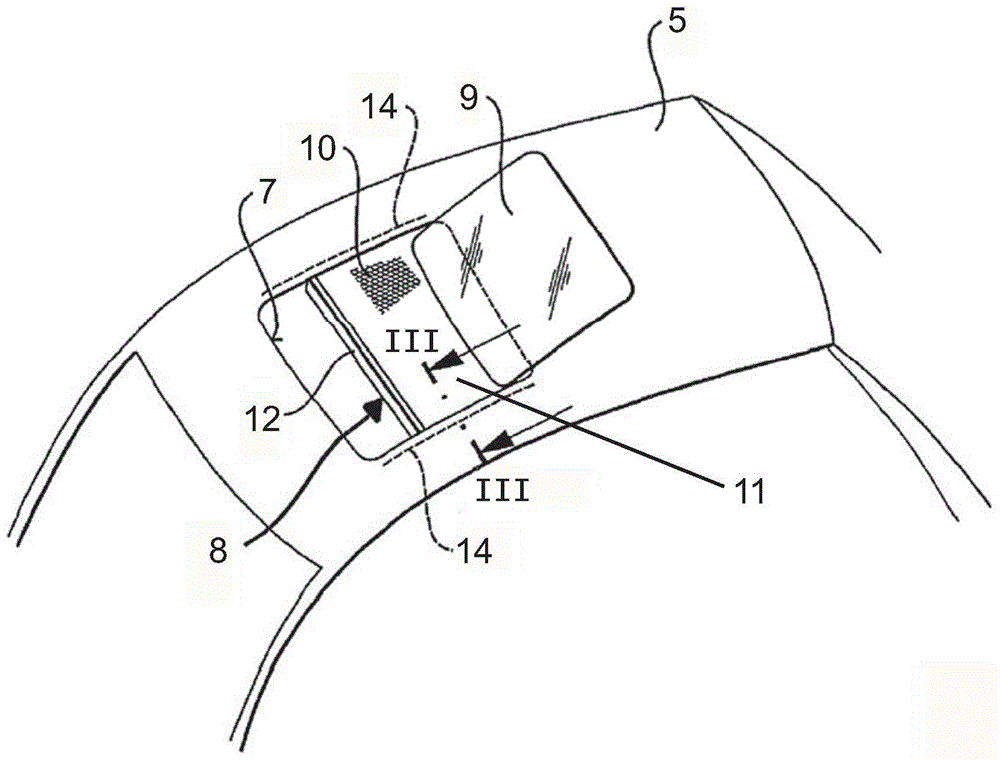

[0041] figure 1Shown is a roof 5 provided with an opening 7 and a roller blind system. The cover 9 of the sliding roof system is joined to the opening 7 . The cover 9 can be in its shaded position closing the opening 7 and is shown in figure 1 Move between the light-transmitting positions in . Below the cover 9 and below the opening 7 there is a roller blind 10 which is part of a roller blind system 8 . The roller blind 10 can move forward and backward based on the vehicle. When the roller blind 10 is fully pushed back, the opening 7 is fully exposed. Fresh air and sunlight can freely enter the car interior space. The opening 7 is covered by the roller blind 10 when the roller blind 10 is fully advanced. Fresh air and sunlight can thus only enter the vehicle interior to a limited extent.

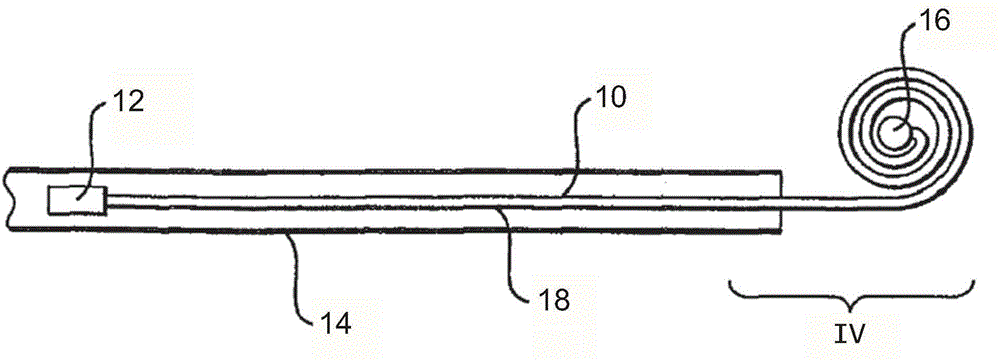

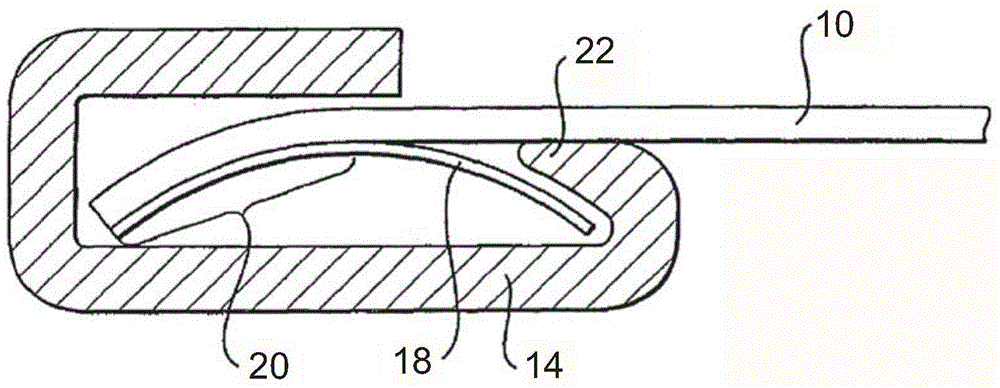

[0042] The roller blind 10 comprises a roller blind fabric 11 of flexible material such as cloth or plastic film. The front end of the roller shade fabric is provided with a transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com