Tailing removal method of cold shear machine

A cold shearing machine and tail sweeping technology, which is applied in the field of steel processing to prevent the overturn from being blocked, support the overturning smoothly, and facilitate the hinged installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

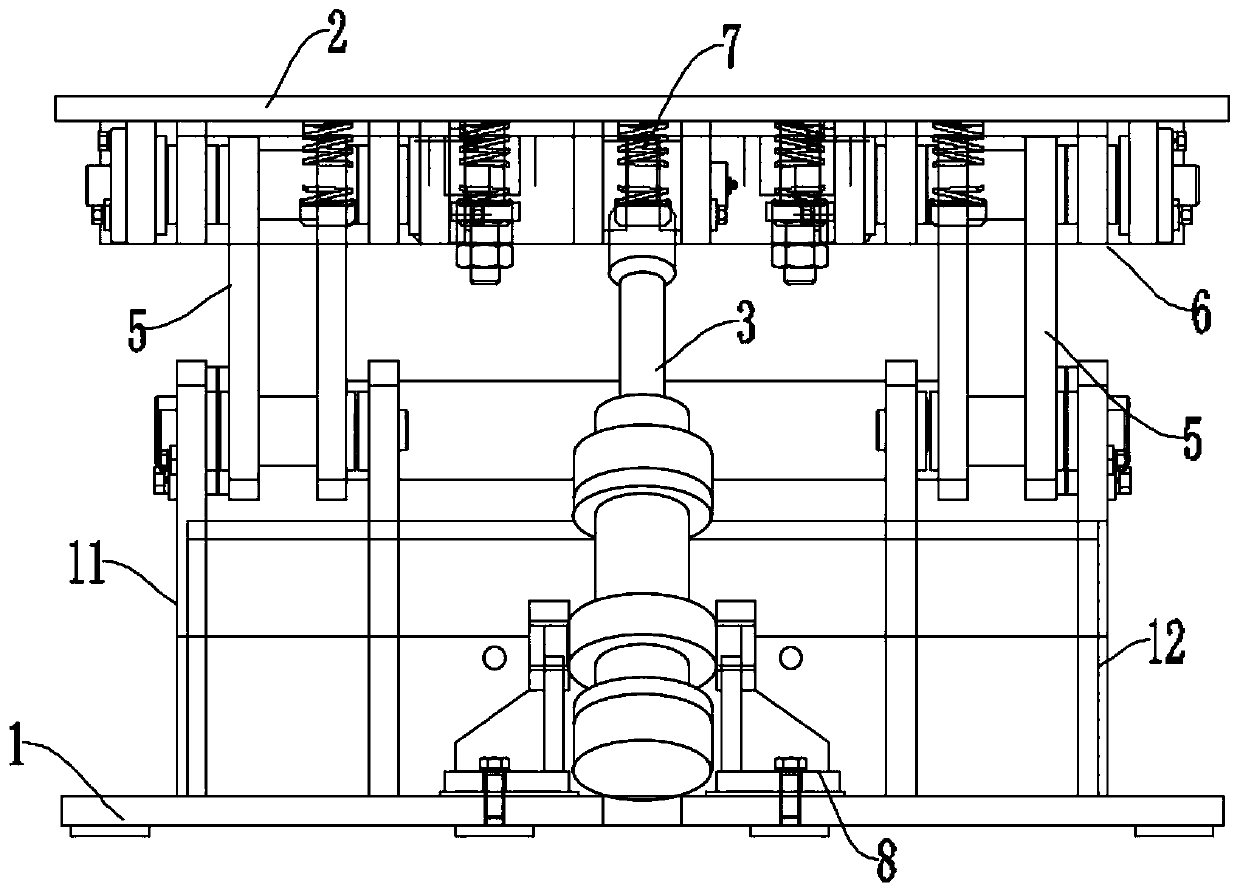

[0039] A new type of tailing device for cold shears is used in the cold shearing production line of steel. It is arranged before the upper and lower cutting edges of the cold shears. After the steel is cut, the remaining steel tails on the platen are removed by turning the platen. The specific structure and working principle are described in detail below.

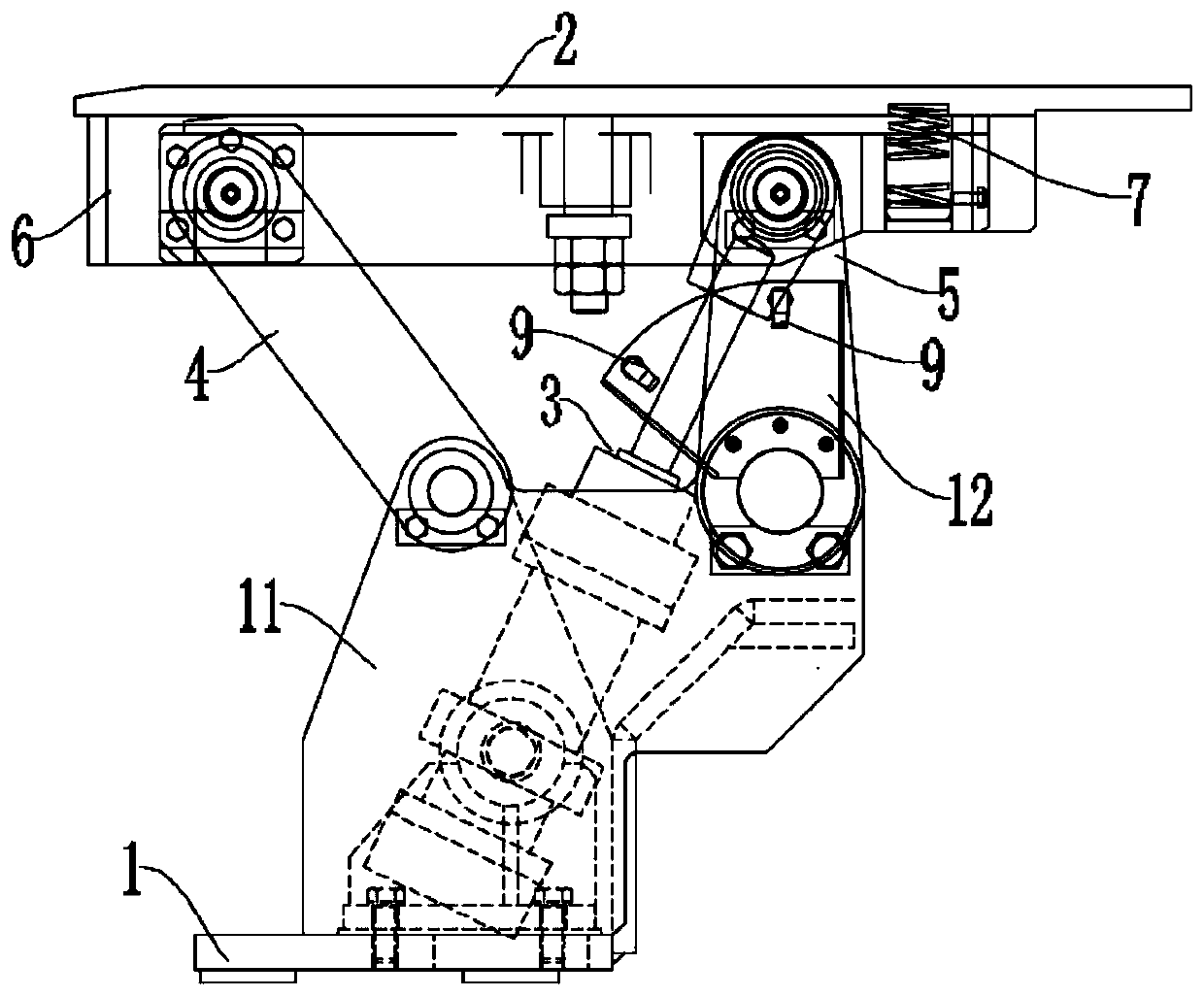

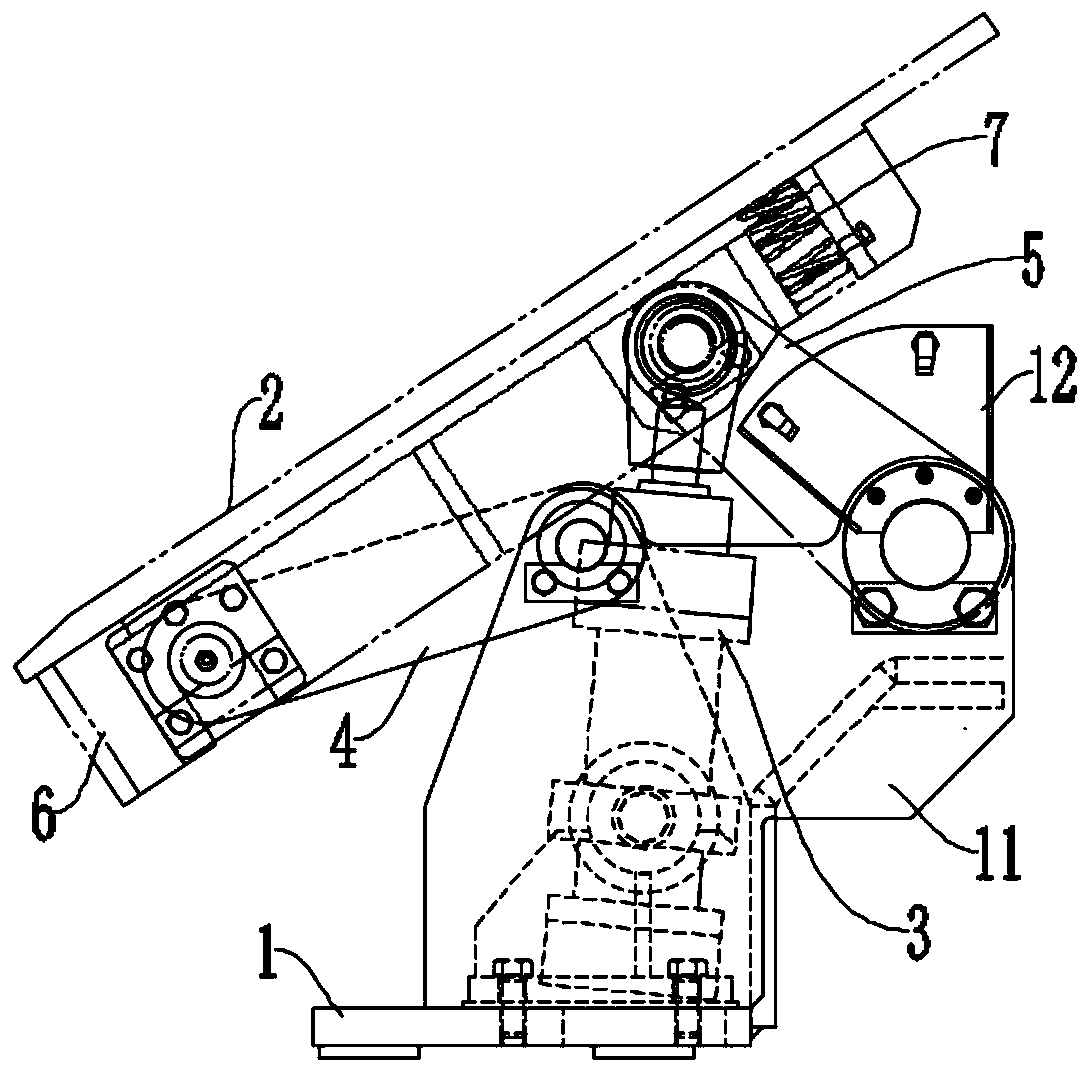

[0040] Such as Figure 1 to Figure 3 As shown, the tailing device of the cold shear mainly includes a base 1 as an installation base, a platen 2 for receiving steel, a drive cylinder 3 for turning over the console plate 2, a front rocker 4 and a rear rocker 5 . Wherein, one end of the driving cylinder 3 , the front rocker 4 and the rear rocker 5 are all hingedly connected to the platen 2 , and the other end is hingedly connected to the base 1 .

[0041] Specifically, in order to provide more convenient installation space for the drive cylinder 3, the front rocker 4 and the rear rocker 5, a pair of supports 11 are symmetric...

Embodiment 2

[0049] Such as Figure 4 As shown, it is a cold shearing production line with a relatively compact layout space. When the cold shearing machine shears steel, the platen is close to the side wall of the lower shearing edge a, and the upper shearing edge b and the steel pressing mechanism c are cold. The other parts of the shearing machine are all located above the lower cutting edge a and the platen, and there are devices such as guide rollers at the other end of the platen, which are not shown in the figure. In this case, it is difficult to arrange independent process equipment on the side and above the platen, and remove the tailings by pushing the material above the roller table of the platen. Even if independent process equipment can be arranged, due to Removal is done by pushing the tail off the rear end, so it is difficult to divide the longer tail.

[0050] Therefore, the inventor considers that an oil cylinder is arranged below the platen, and the console plate is flip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com