A brake valve with non-decompression direct supply capability

A technology of pressure reducing valve and brake valve, which is applied to vehicle components, control valves, air release valves, brake components, etc., can solve problems such as potential safety hazards, achieve easy use and maintenance, simplify braking systems, and improve reliability and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

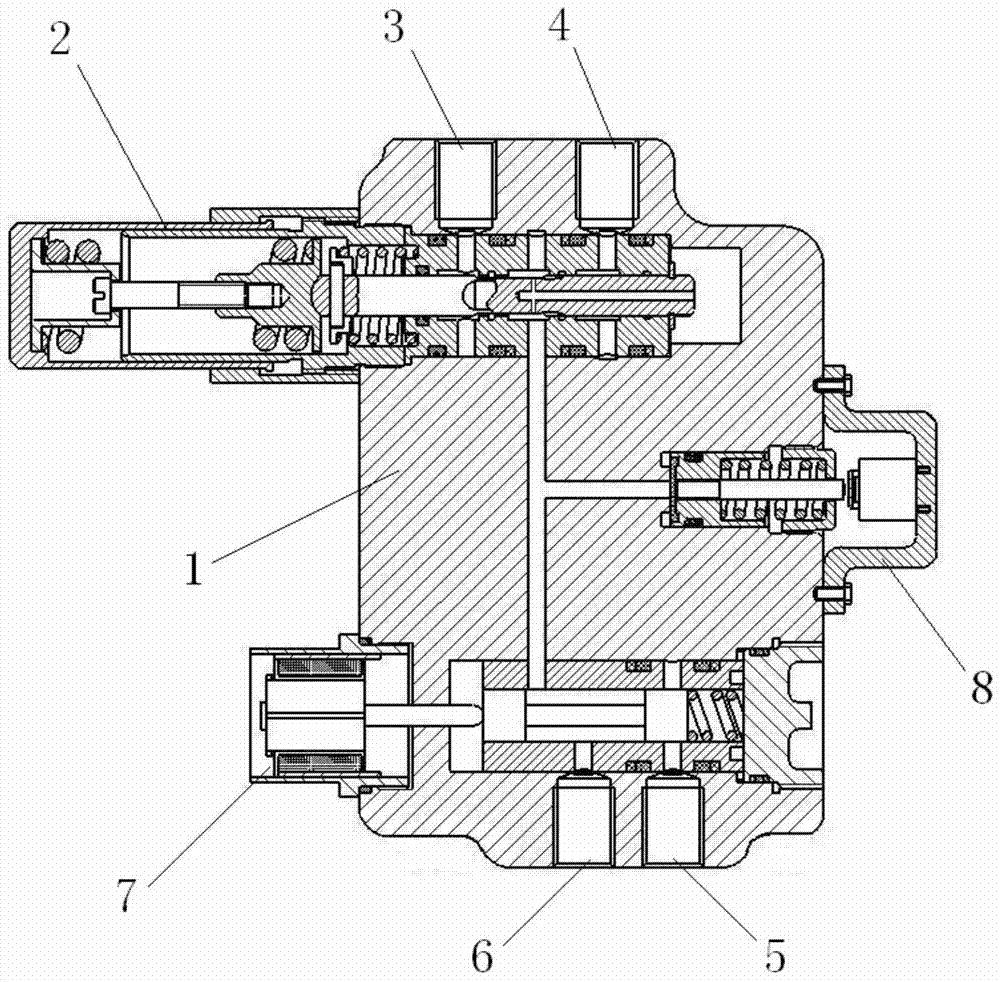

[0018] This embodiment is a brake valve with non-decompression direct supply capability, which includes a housing 1, a brake decompression valve 2, electric valves 7 and 8 hydraulic switches.

[0019] The brake pressure relief valve 2, the electric valve 7 and the hydraulic switch 8 share a housing 1, which are respectively installed in three inner cavities of the housing 1, and the housing 1 is an assembly frame, It is also an integral part of the brake pressure reducing valve 2, the electric valve 7 and the hydraulic switch 8.

[0020] There are three chambers in the housing 1, which are respectively the brake pressure reducing valve chamber, the electric valve chamber and the hydraulic switch chamber, and the brake pressure relief valve 2, the electric valve 7 and the hydraulic switch 8 are respectively installed in the in each chamber. The chambers communicate with each other through oil passages.

[0021] There are two oil passages communicating with each chamber in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com