Fan of asynchronous motor

A technology for asynchronous motors and fans, which is applied to electric components, machines/engines, liquid fuel engines, etc. It can solve the problems of increased manufacturing costs of fan blades, damage to asynchronous motors, waste of materials, etc., to ensure heat dissipation effect, narrow overall structure, The effect of reducing humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

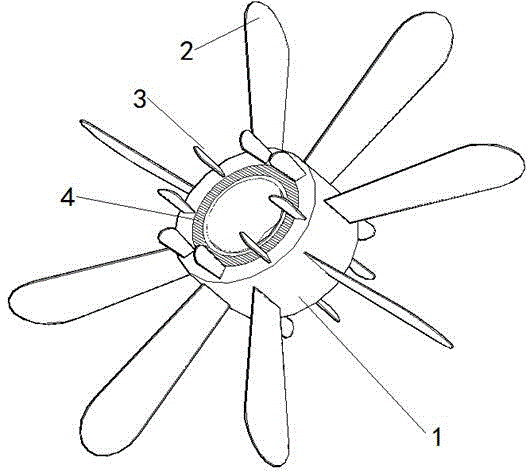

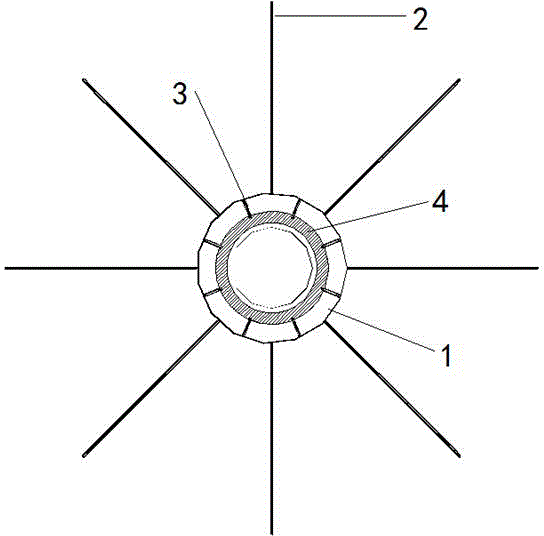

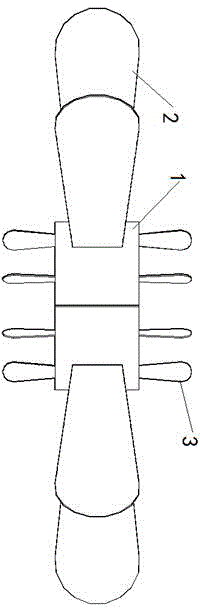

[0019] exist figure 1 , figure 2 with image 3 Among them, a fan of an asynchronous motor is arranged in the windshield of the asynchronous motor, and includes a ring-shaped body 1, and a plurality of A-shaped blades 2 are arranged at equal intervals on the outer arc surface of the body 1, and the A-shaped blades 2 is in the shape of a sheet with an arc-shaped upper end, and several B-shaped blades 3 are arranged at equal intervals on the left and right sides of the body 1. The shape of the B-shaped blades 3 is the same as that of the A-type blades 2. The A-type blades 2 are misplaced, that is, each B-type blade 3 is located between two adjacent A-type blades 2, which enhances the heat dissipation effect. A hollow layer 4 is provided inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com