Point Vector Enveloping Method for Determining Tool Profile in Helical Surface Forming

A technology for helical surface and forming processing, applied in the design and manufacture of helical surface forming and machining tools, and the field of helical surface manufacturing, can solve problems such as difficult to establish a general computer method, tedious formula derivation mathematical calculation, etc., which is conducive to the realization of programming , high robustness, good effect of optimization of motion trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

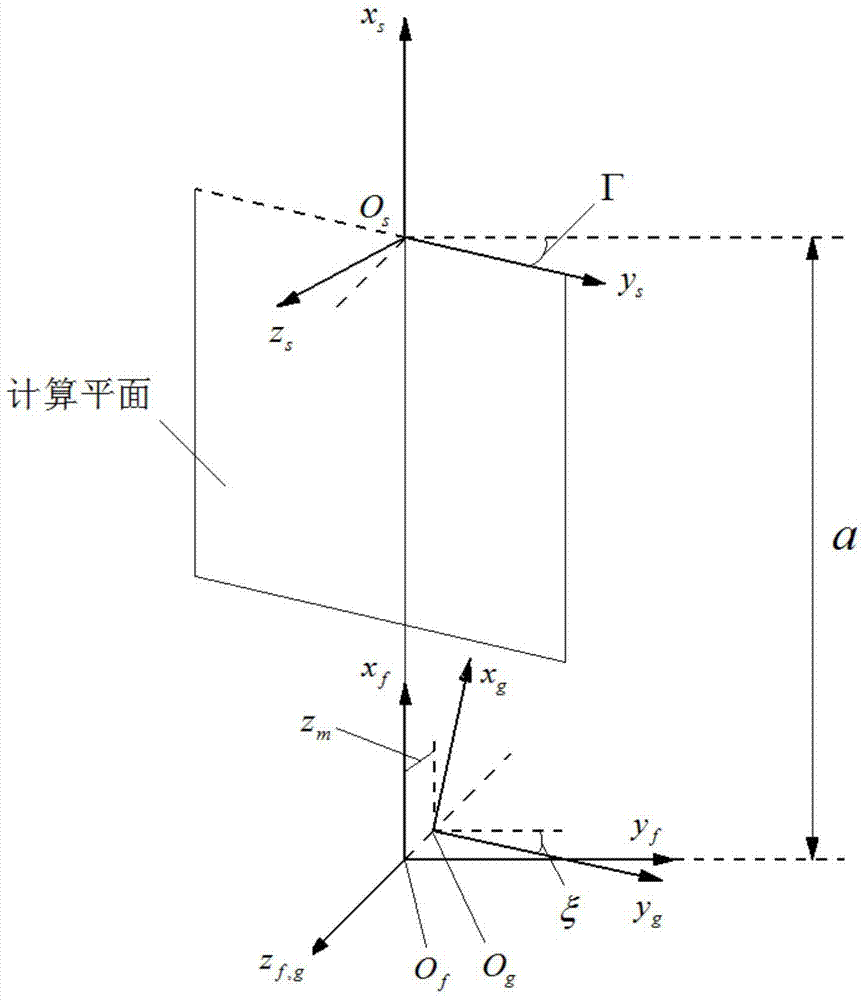

[0021] Taking the grinding of a standard involute helical gear with a profiled grinding wheel as an example, the point-vector envelope method for determining the profile of a tool in forming a helical surface includes the following steps:

[0022] 1) Point discretization is carried out on the profile line of the end face of the helical gear, and the profile line of the gear end face is discretized according to the equiangular discretization criterion, and a series of plane points evenly distributed on the profile line are obtained.

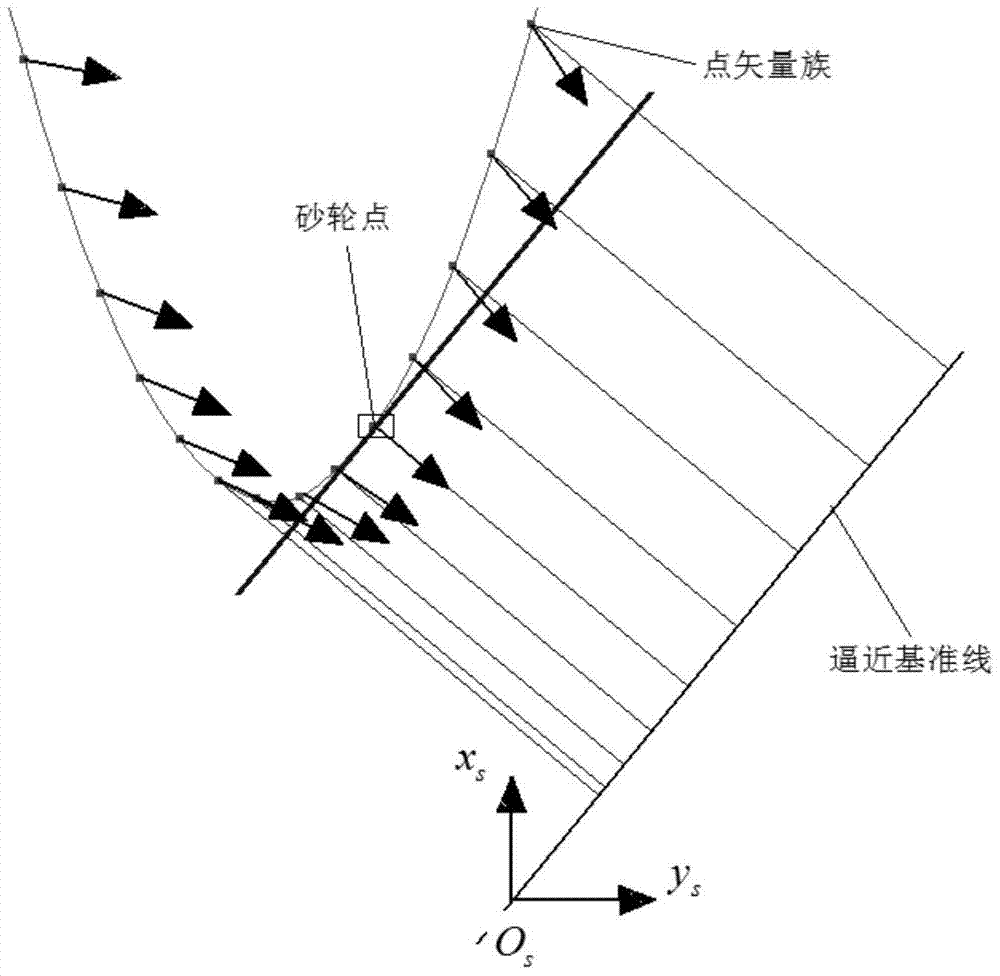

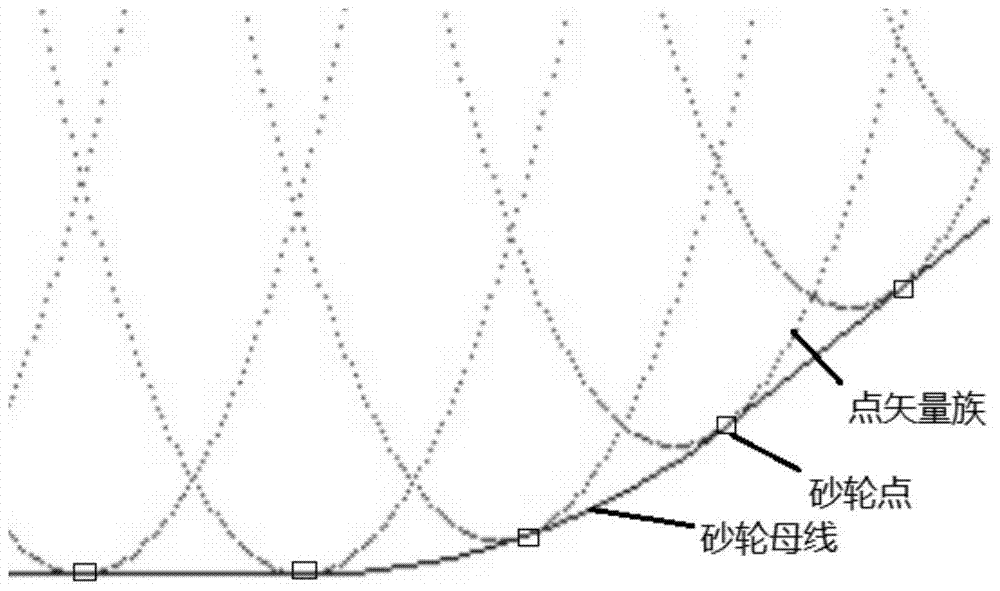

[0023] 2) Add its space vector characteristics to all discrete points on the profiled line, first determine the direction of the plane vector at each discrete point on the profiled line; then according to the self-enveloping characteristics of the helical surface, the point is represented by the plane norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com