A multi-scale finite element modeling method for welded box-section steel joints

A modeling method and multi-scale technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of insufficient monitoring, inability to monitor local key parts of the structure, and limited number of sensors installed, so as to ensure structural safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing:

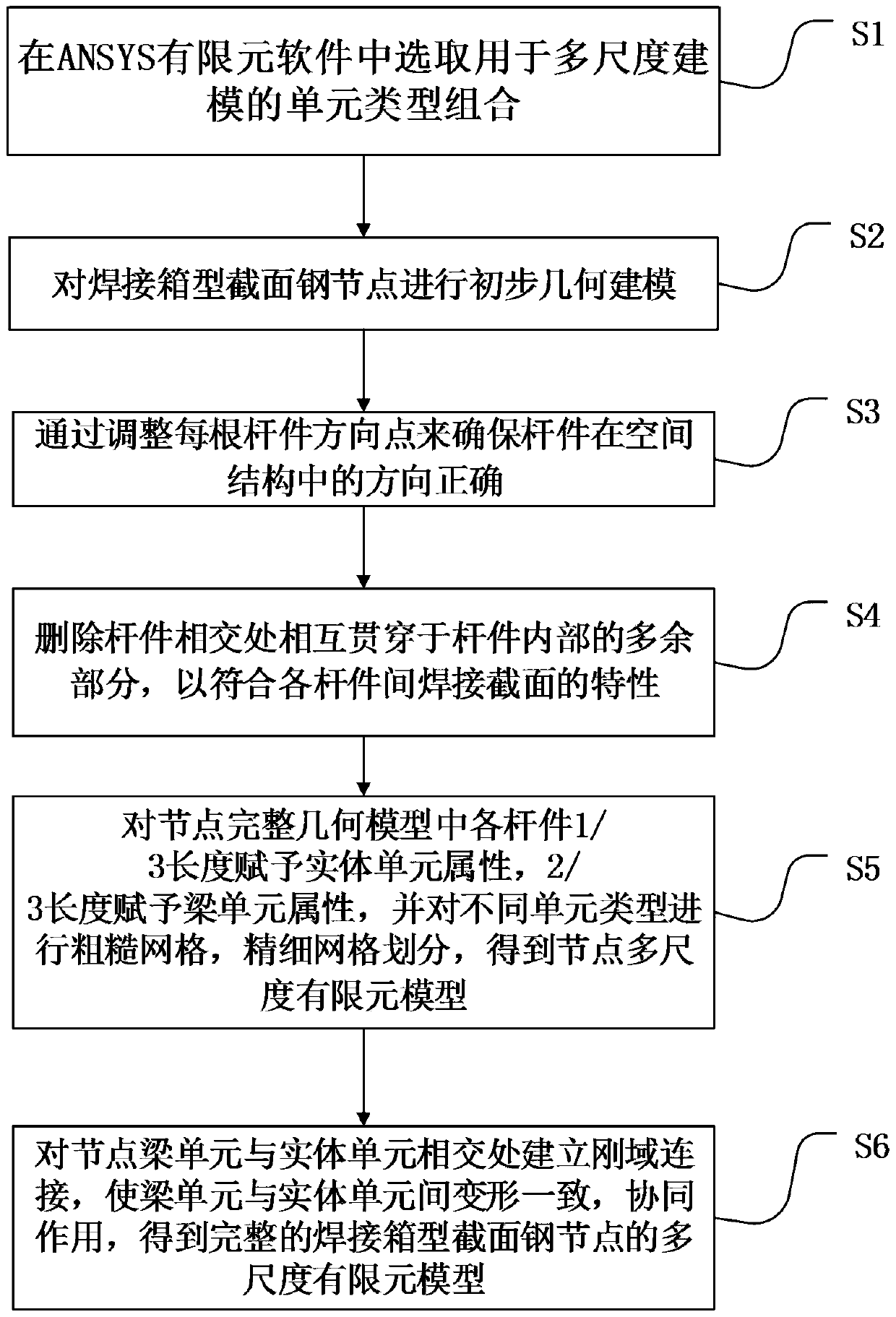

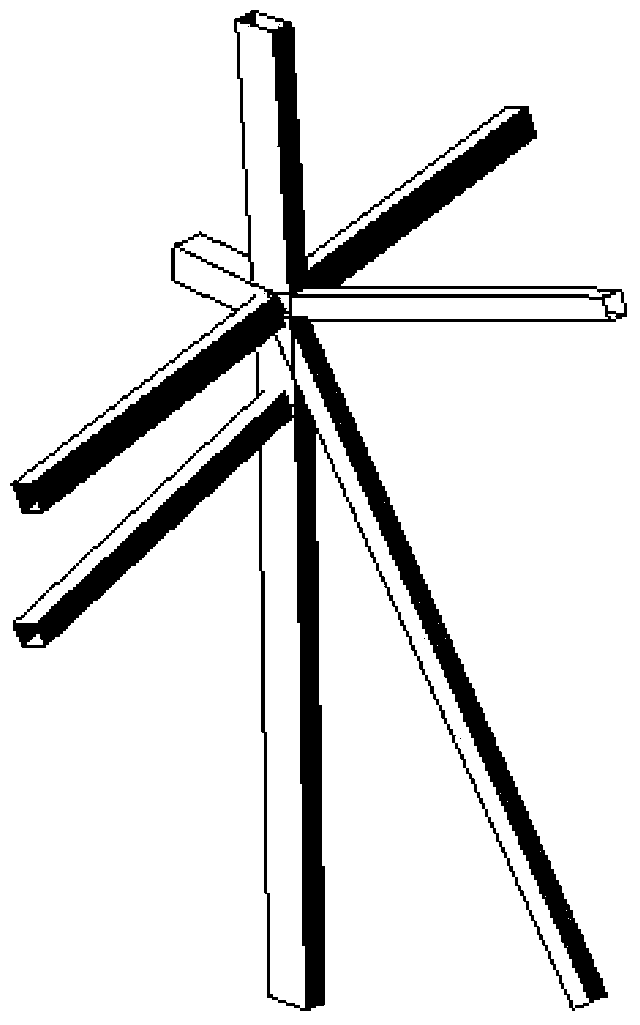

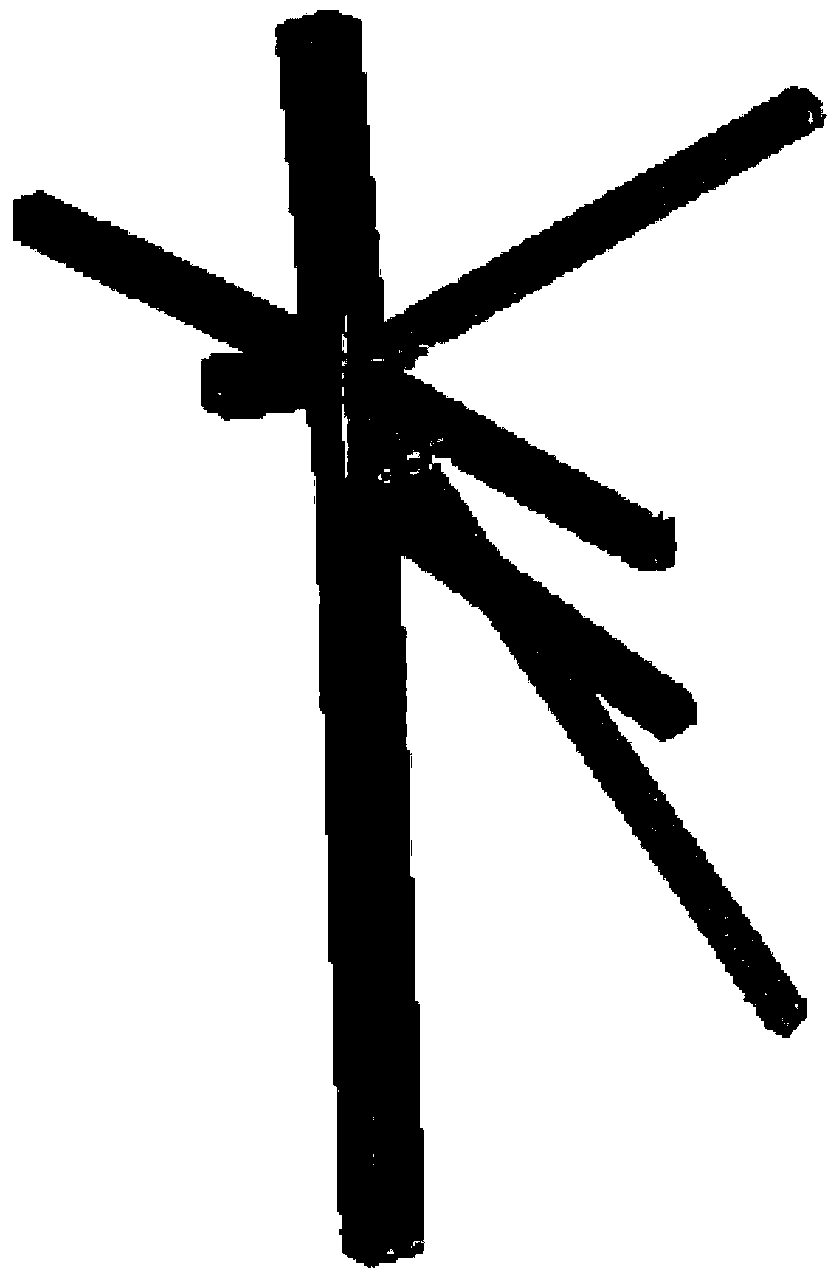

[0047] The joint type of the welded box-section steel joints in the present invention is different from that of various commonly used spherical joints. The construction technology requirements of the welded box-section bars are relatively high, and the joint types are novel. Combining with the above multi-scale finite element model, a multi-scale finite element model of welded box-section steel joints is established to obtain local detail information of the joints. Due to the novel form of welded box-section steel nodes, it is increasingly used in large-scale grid structures, which play an important role in supporting the grid structure, connecting the members in the structure, and transmitting and distributing moment. Therefore, if figure 1 As shown, the present invention provides a multi-scale finite element modeling method for welded box-section steel nodes, especially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com