Dual-layer oil tank made of glass fiber, manufacturing method thereof and special mold

A glass fiber, double-layer oil tank technology, applied in the direction of glass/slag layered products, household appliances, chemical instruments and methods, etc., can solve the problems of pollution, oil loss environment, erosion and electrolytic corrosion, etc., to reduce manufacturing Cost, prevention of water vapor attack and electrolytic corrosion, effect of reducing the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

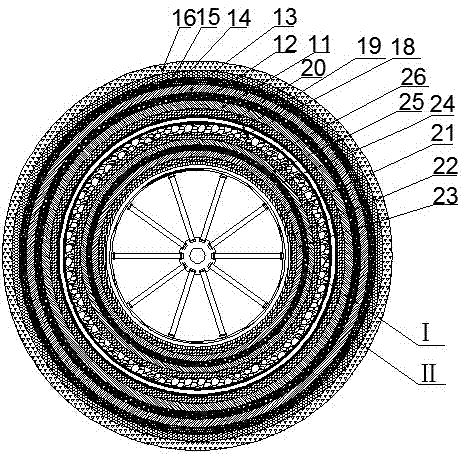

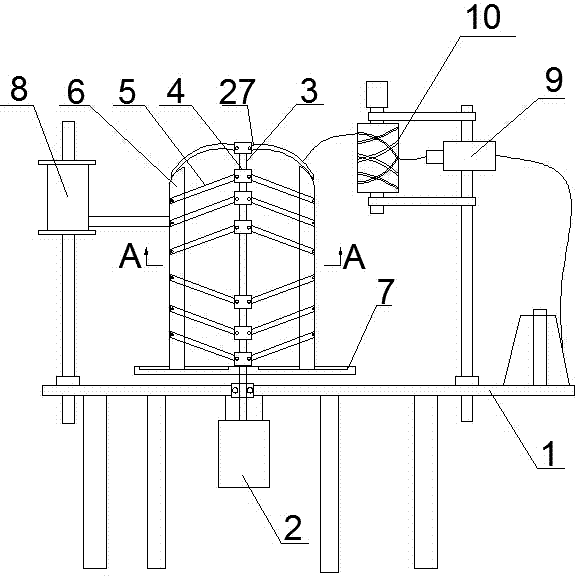

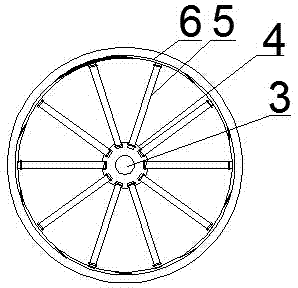

[0027] according to Figures 1 to 3 As shown, the present invention relates to a double-layer oil tank made of glass fiber, which includes a storage inner tank I made of glass fiber and a reinforced tank II bonded to the outer surface of the inner tank made of glass fiber. Between the inner tank I and the reinforced tank II, there is also a glass fiber sleeve 19 that doubles as a reinforcing rib, and several optical fibers are arranged in the through pipe of the glass fiber sleeve 19 at intervals and are respectively arranged in the tubes of the glass fiber sleeves. The sensor at the bottom of the glass fiber sleeve 19 is connected, and the glass fiber sleeve 19 is filled with unsaturated polyester resin; The first glass fiber spun yarn cloth 22, the first S-twisted yarn layer 23, the first glass fiber staple fiber layer 24, the first Z-twisted yarn layer 25, the first glass fiber ply roving 26 and anti-corrosion The solidified layer 18 is bonded sequentially; the reinforced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com