Corrugated paper based kitchen water purification machine cushion-packaging structure and production method thereof

A technology of buffer packaging and buffer structure, applied in packaging and other directions, can solve the problems of difficult natural degradation of foam plastic materials, high storage and transportation costs, and expensive foam production molds, achieving good adaptability and saving logistics costs. , Solve the effect of high packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

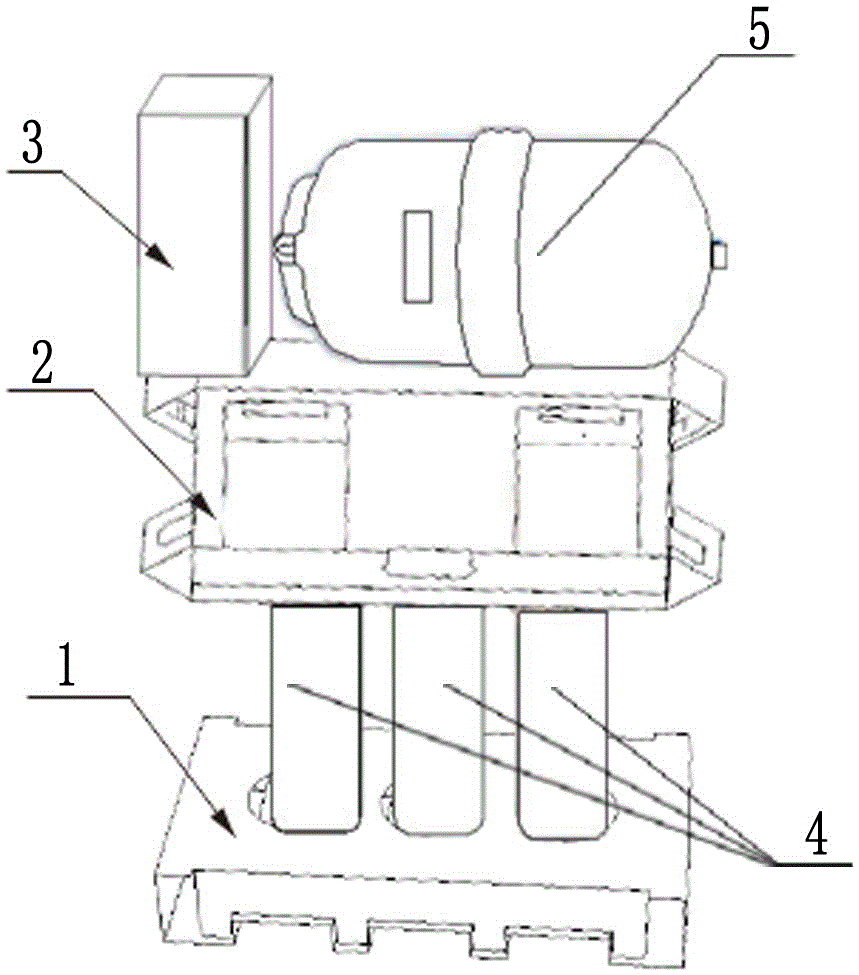

[0033] As shown in the figure, the corrugated paper-based buffer packaging structure for kitchen water purifiers is used for buffer packaging during transportation. A bottom buffer 1, a main liner 2 and an accessory box 3 are provided in the outer packaging box. The bottom liner Body 1, main lining body 2 and accessory box 3 are folded from a piece of corrugated paper, and the area between the bottom lining body 1 and the main lining body 2 is used to hold the filter cartridge 4 and the main machine in the kitchen water purifier. The above-mentioned accessories box 3 and the pressure barrel 5 in the kitchen water purifier are placed on the top of the main liner 2 .

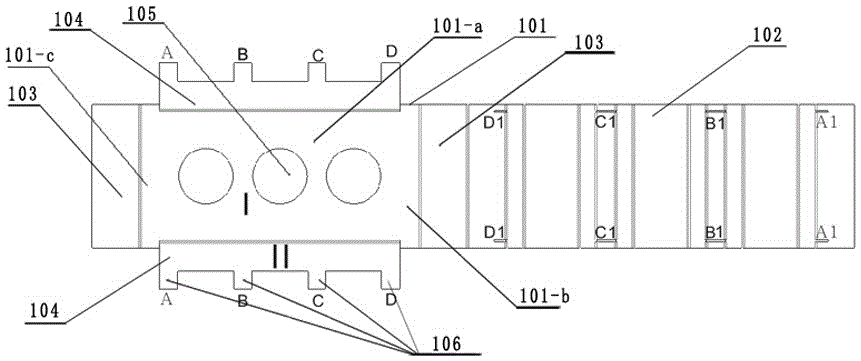

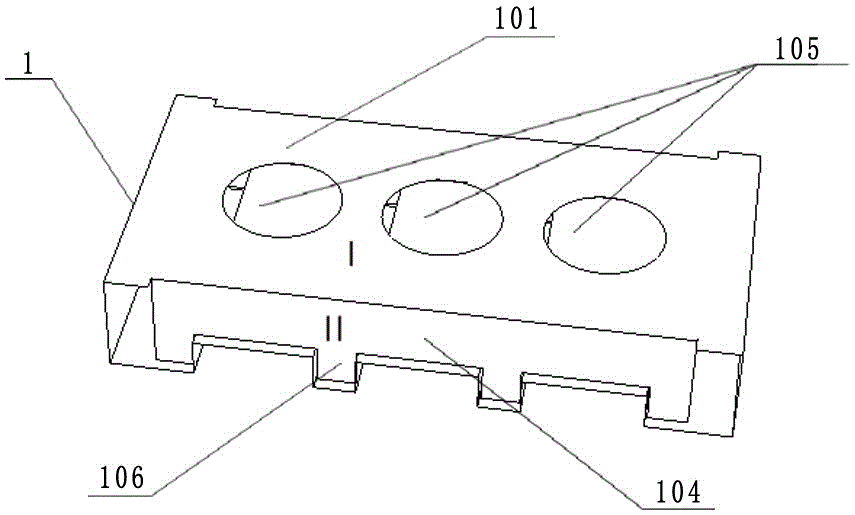

[0034] The bottom liner 1 is a hollow buffer chamber structure surrounded by a top liner 101, a bottom liner 102, two left and right liners 103 connected around the top liner 101 and two front and rear li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com