Used for anti-corrosion paint on the inner wall of the oil pipe and the oil pipe with the inner wall sprayed with anti-corrosion paint

A technology for anti-corrosion coatings and oil pipes, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of non-removal of scaling symptoms, difficulty in ensuring the construction of water injection wells, and difficulty in reducing costs, so as to improve corrosion resistance, resistance to The effect of strong penetration and uniform spray thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

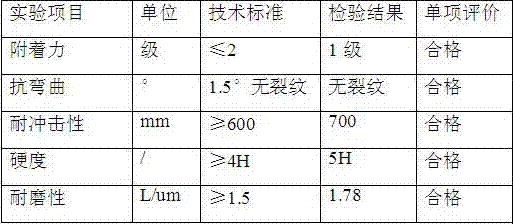

Examples

Embodiment 1

[0018] The anti-corrosion coating used for the inner wall of the oil pipe includes components A and B, specifically including the following components in mass ratio:

[0019] Component A includes modified phenolic resin, mixed solvent, auxiliary agent and auxiliary material. The mass ratio of modified phenolic resin: mixed solvent: auxiliary agent: auxiliary material is 80:5:1:0.7; wherein, mixed solvent includes xylene and butyl Ketones, additives include defoamers, anti-sagging agents and film-forming additives, auxiliary materials include ground calcium carbonate, kaolin and titanium dioxide;

[0020] B component includes accelerator and solvent; Accelerator is the mixture of CYD-128 epoxy resin and bisphenol A, and solvent is butanone; Wherein, the mass ratio of CYD-128 epoxy resin and bisphenol A is 2:2.5, Butanone is an appropriate amount.

[0021] The mass ratio of component A: component B is 3:0.7; it is prepared according to the following process:

[0022] Mix the m...

Embodiment 2

[0027] The anti-corrosion coating used for the inner wall of the oil pipe includes components A and B, specifically including the following components in mass ratio:

[0028] Component A includes modified phenolic resin, mixed solvent, auxiliary agent and auxiliary material. The mass ratio of modified phenolic resin: mixed solvent: auxiliary agent: auxiliary material is 87:10:2:1; among them, mixed solvent includes xylene and butyl Ketones, additives include defoamers, anti-sagging agents and film-forming additives, auxiliary materials include ground calcium carbonate, kaolin and titanium dioxide;

[0029] Component B includes an accelerator and a solvent; the accelerator is a mixture of CYD-128 epoxy resin and bisphenol A, and the solvent is butanone;

[0030] The mass ratio of component A: component B is 5:1.

[0031] Others are basically the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0033] The anti-corrosion coating used for the inner wall of the oil pipe includes components A and B, specifically including the following components in mass ratio:

[0034] Component A includes modified phenolic resin, mixed solvent, auxiliary agent and auxiliary material, and the mass ratio of modified phenolic resin: mixed solvent: auxiliary agent: auxiliary material is 90:15:3:2; wherein, mixed solvent includes xylene and butyl Ketones, additives include defoamers, anti-sagging agents and film-forming additives, auxiliary materials include ground calcium carbonate, kaolin and titanium dioxide;

[0035] Component B includes an accelerator and a solvent; the accelerator is a mixture of CYD-128 epoxy resin and bisphenol A, and the solvent is butanone;

[0036] The mass ratio of component A: component B is 7:2.

[0037] Others are basically the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com