Glass fiber reinforced plastics twin-wall oil tank, preparation method and special mould thereof

The technology of glass fiber reinforced plastic and oil storage tank is applied in the field of glass fiber reinforced plastic double-wall oil storage tank and its preparation, which can solve the problems of short service life, short service life and poor corrosion resistance of the oil storage tank, and achieve weight reduction and strong anti-penetration ability. , the effect of reducing the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure of the FRP double-wall oil storage tank provided by the present invention and its preparation method will be further described in detail below in conjunction with the accompanying drawings.

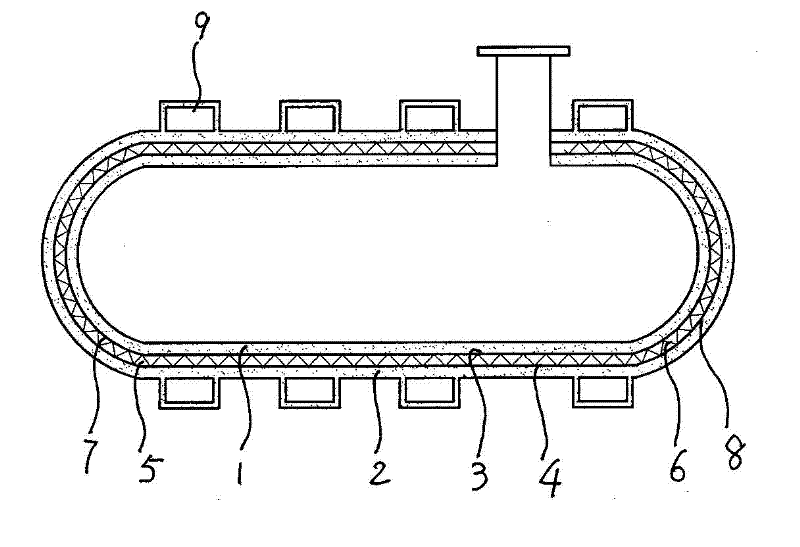

[0033] Such as figure 1 Shown is a schematic structural view of the FRP double-wall oil storage tank body provided by the present invention. Its structure includes an inner tank body 1, an outer tank body 2, and a double-walled structure composed of an outer wall surface 3 of the inner tank body and an inner wall surface 4 of the outer tank body. There is a continuous cavity 5 between the double-walled structures. "W" or "V" bulked glass fiber yarns 6 bonded to the double walls are distributed between the double-wall structures in the continuous cavity, wherein the bonded glass fiber yarns 6 have a density of 20 to 80 (root or bundle) yarns per square centimeter to satisfy the double wall with sufficient bonding strength and form a gap; Curable resin; the outer tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com