Method and device for detecting height line of stacked grain

A detection method and detection device technology, which are applied in image data processing, instruments, calculations, etc., can solve the problem of no stacking grain height line detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In the embodiment of the present invention, by modeling the color space where the pile height line is located, and using an edge detection algorithm to find the upper and lower edges of the pile height line, the position of the pile height line can be accurately detected.

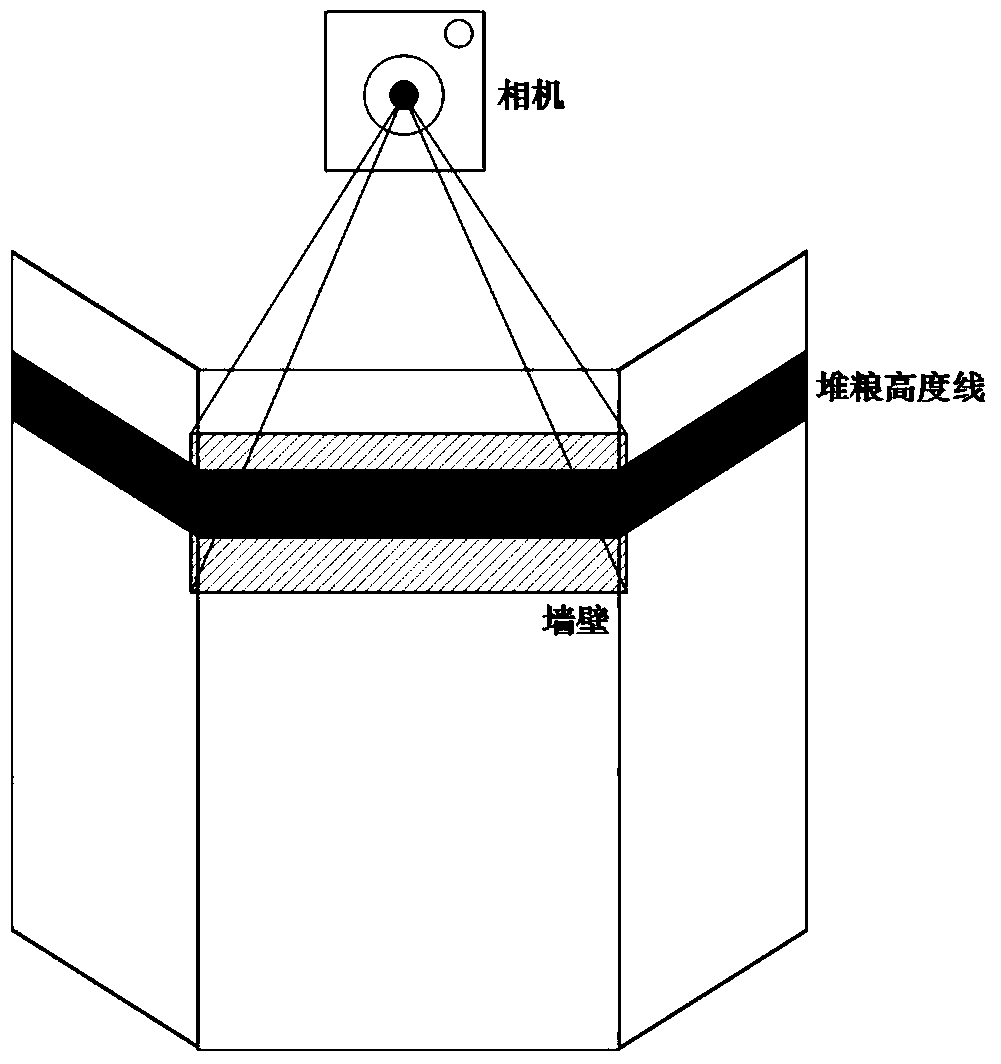

[0067] In the embodiment of the present invention, a camera is installed on the top of the wall opposite to the height line of the pile to be detected, and the camera preferably adopts a telecentric lens with less distortion. The schematic diagram of a camera provided in this embodiment for taking pictures of a wall where a grain height line is set is as follows: figure 1 As shown, when the camera is installed, the grain height line is as horizontal as possible in the image, and the optical axis of the camera is as perpendicular as possible to the wall surface of the grain height line to be detected, so that the camera can capture as few other walls as possible.

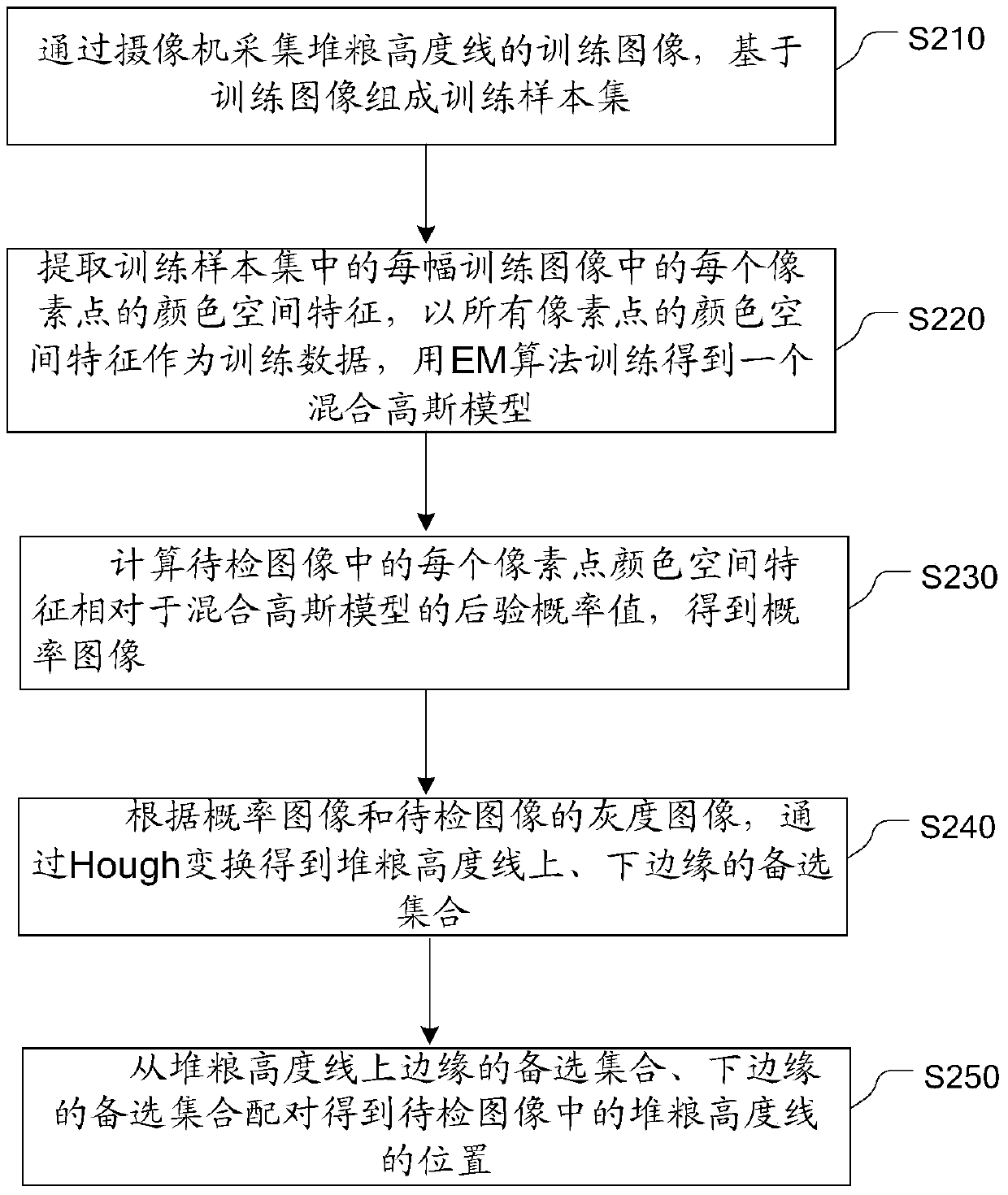

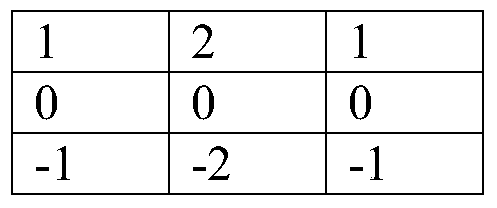

[0068] The processing flow of a method fo...

Embodiment 2

[0097] This embodiment provides a device for detecting the height line of piles, and its specific structure is as follows Figure 4 As shown, including the following modules:

[0098] The training sample set construction module 41 is used to collect training images of the grain height line through a camera, and form a training sample set based on the training images;

[0099] The Gaussian mixture model construction module 42 is used to extract the color space features of each pixel in each training image in the training sample set, use the color space features of all pixels as training data, and train the above training data with the EM algorithm to obtain one GMM, denoted as model Θ. The trained GMM represents the distribution of pixel color space features.

[0100] The probability image acquisition module 43 is configured to calculate the posterior probability value of the color space feature of each pixel in the image to be inspected relative to the Gaussian mixture model to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com