Position detector

A detector and detection object technology, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

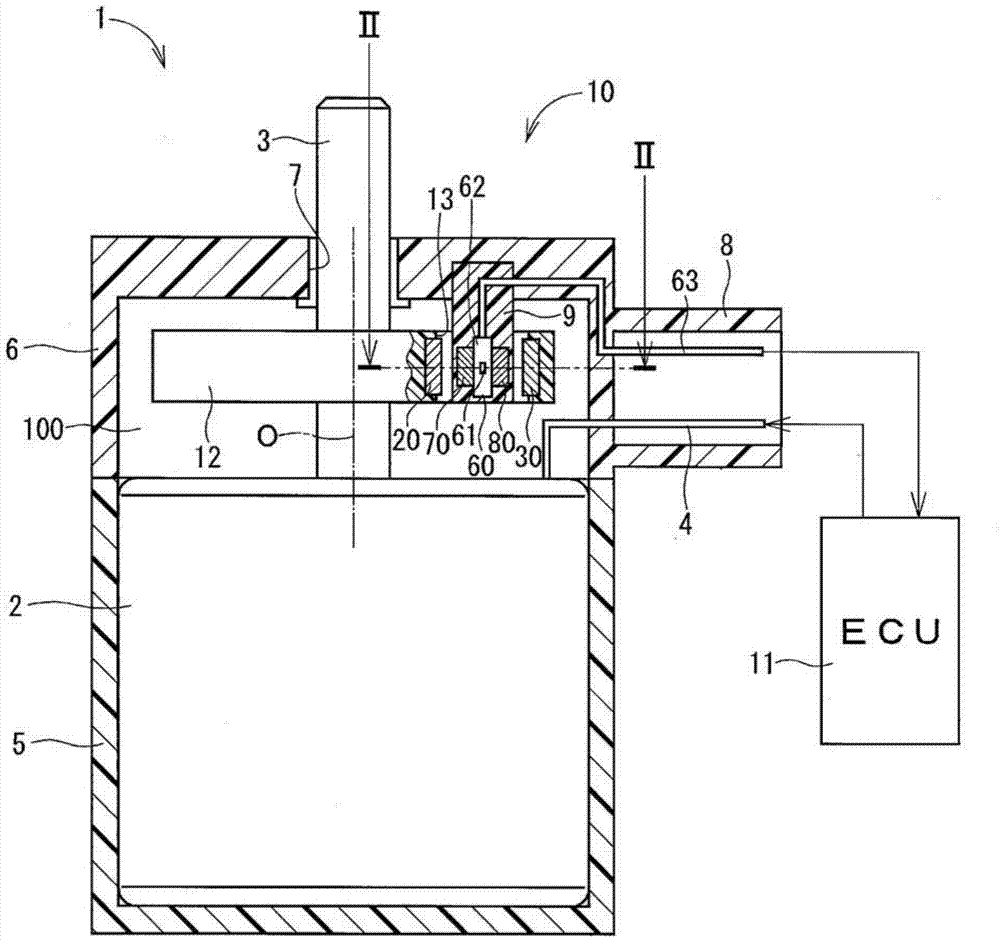

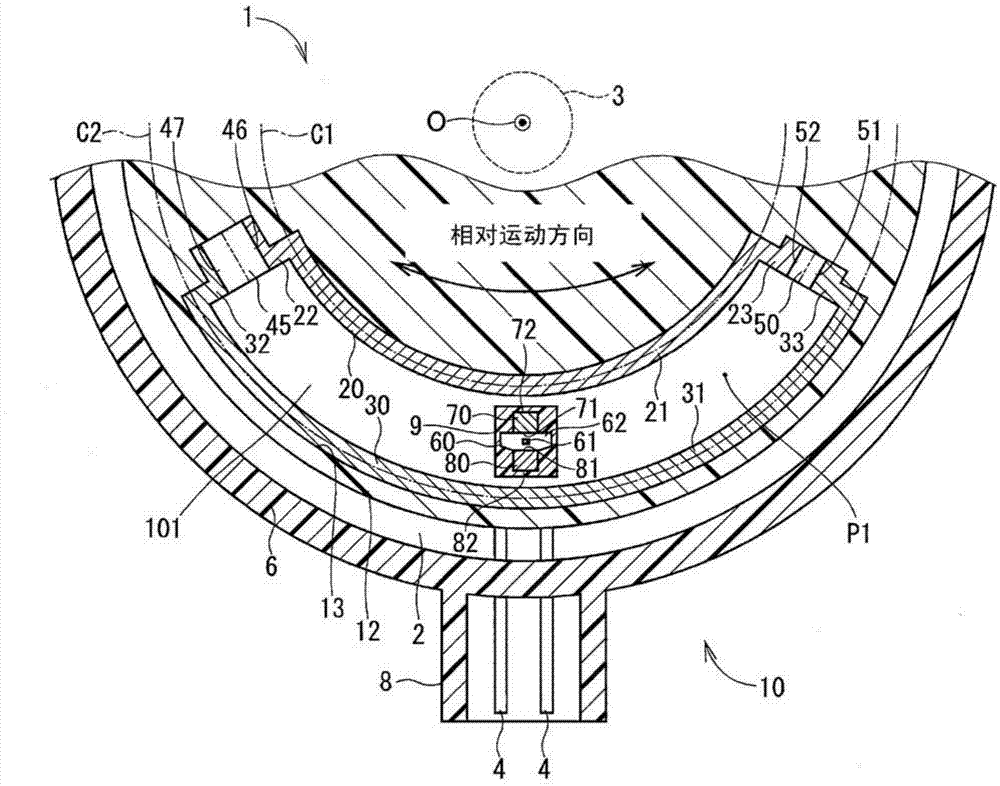

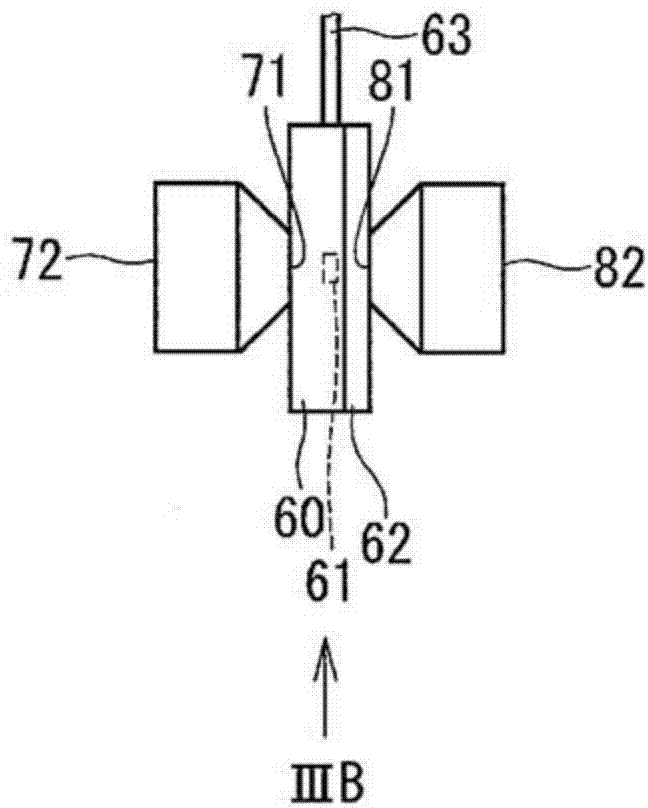

[0035] figure 1 with figure 2 The position detector and the actuator using the position detector in the first embodiment of the present invention are shown in .

[0036] For example, the actuator 1 is used as a driving power source for driving a throttle valve (throttle valve) of a vehicle (not shown). The actuator 1 is provided with a motor 2 , a housing 5 , a cover 6 , an electronic control unit (hereinafter, “ECU”) 11 , a rotating body 12 , a position detector 10 , and other components.

[0037] Such as figure 1 As shown, the motor 2 has an output shaft 3, a motor terminal 4 and the like. Electric power is supplied to the motor 2 via the motor terminal 4 . The motor 2 rotates by receiving electric power from the terminal 4 . The rotation of the motor 2 is output from an output shaft 3 . For example, the output shaft 3 is connected to a throttle valve through a gear set (not shown) or the like. Therefore, when the motor 2 rotates, the throttle valve also rotates.

...

no. 2 example )

[0086] exist Figure 6 The position detector in the second embodiment of the present disclosure is shown in . In the second embodiment, the first magnetic flux generator is different from the first magnetic flux generator in the first embodiment.

[0087] According to the second embodiment, the first magnetic flux generator has two magnets 40 . The magnet 40 is the magnet shown in the above comparative example. That is, magnet 40 and magnet 50 are each constructed to have the same magnet volume, same magnet type (e.g., neodymium magnet, ferromagnet, etc.), same material composition (e.g., if magnets 40, 50 are neodymium magnets, the same ratio of neodymium, iron, boron and the same content ratio of dysprosium, etc.; or if the magnets 40, 50 are ferromagnets, the same content ratio of barium, strontium, etc.) and permanent magnets of the same magnetization adjustment method.

[0088] Such as Figure 6 As shown in , in this embodiment, two magnets 40 are arranged in parallel b...

no. 3 example )

[0094] exist Figure 7 The position detector in the third embodiment of the present disclosure is shown in . According to the third embodiment, the position detector 10 has a third magnetic flux transmission part 53 . The third magnetic flux transmission part 53 is disposed at a position between the second end 23 of the first magnetic flux transmission part 20 and the second end 33 of the second magnetic flux transmission part 30 , and is connected with the first magnetic flux transmission part 20 The same material as that of the second magnetic flux transmission part 30 is made to be integrated with the first magnetic flux transmission part 20 and the second magnetic flux transmission part 30 . That is, in other words, the configuration of the position detector 10 in the third embodiment can be described as replacing the magnet 50 of the comparative example described above with the third magnetic flux transmission member 53 .

[0095] According to the present embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com