Cable branch box distribution wall bushing and its connection assembly

A technology of cable branch boxes and wall bushings, applied in the direction of cable joints, etc., can solve the problems of inability to connect live, economic loss, large blackout range, etc., and achieve the effect of reducing the power outage range, improving power supply efficiency, and expanding the power outage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

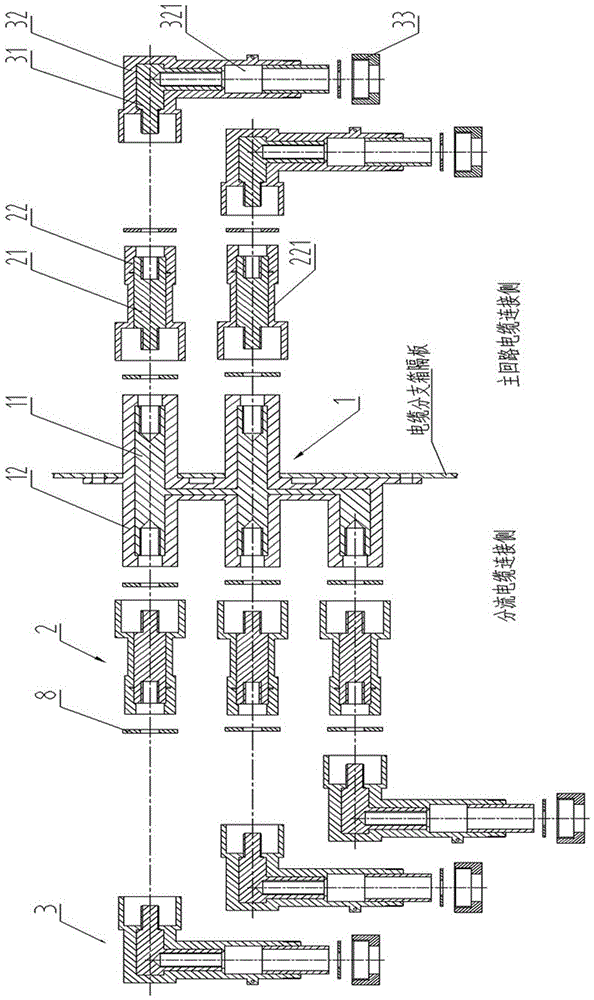

[0021] Preferred embodiment one, such as figure 1 As shown, this embodiment discloses a cable branch box shunt wall bushing and its connection assembly, including a type I shunt wall bushing 1, a type I butt joint 2 and an external thread head type L-shaped cable connection terminal 3 , the L-shaped cable connection terminal 3 is connected with the I-type shunt wall bushing 1 through the I-type butt joint 2 to form an assembly.

[0022] Type I shunt wall bushing 1 is an integral part of the conductive connecting body 11 and the hard insulating sleeve 12 embedded in the conductive connecting body 11. The side through the wall is the main circuit cable connection side, and the opposite side is the shunt cable connection side. ; The main circuit cable connection side of the conductive connecting body 11 is connected in parallel with two internal thread connection ends, and the shunt cable connection side is connected in parallel with three internal thread connection ends, and the...

Embodiment 2

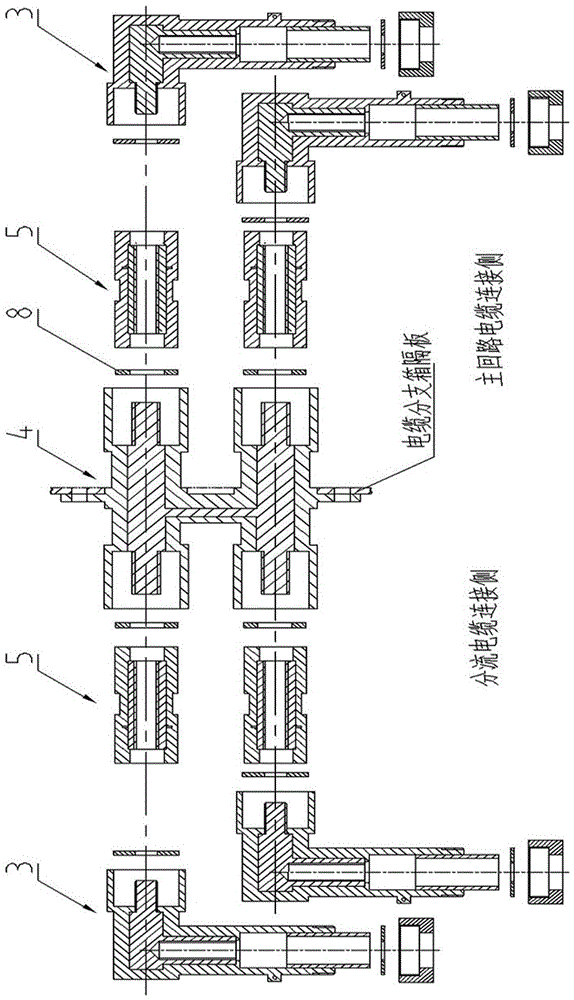

[0027] Preferred embodiment two, such as figure 2 As shown, the difference between this embodiment and the preferred embodiment 1 is that: the shunt wall bushing and the butt joint are respectively Type II shunt wall bushing 4 and Type II butt joint 5, and the Type II shunt wall bushing 4 and I The difference between Type II shunt wall bushing 1 is that two external thread connection ends of the coaxial center line are connected in parallel on both sides, so that Type II shunt wall bushing 4 forms an "I"-shaped structure, and its hard insulating sleeve The outer diameters of the two ends are larger than the outer diameters of the external thread connection ends of the conductive connecting body, so that the two ends of the hard insulating sleeve form an arc extinguishing chamber. The internal conductive butt joint body of type II butt joint 5 is an internal threaded pipe, and the corresponding external hard insulating sleeve is a straight tube type sleeve, and its two ends fo...

Embodiment 3

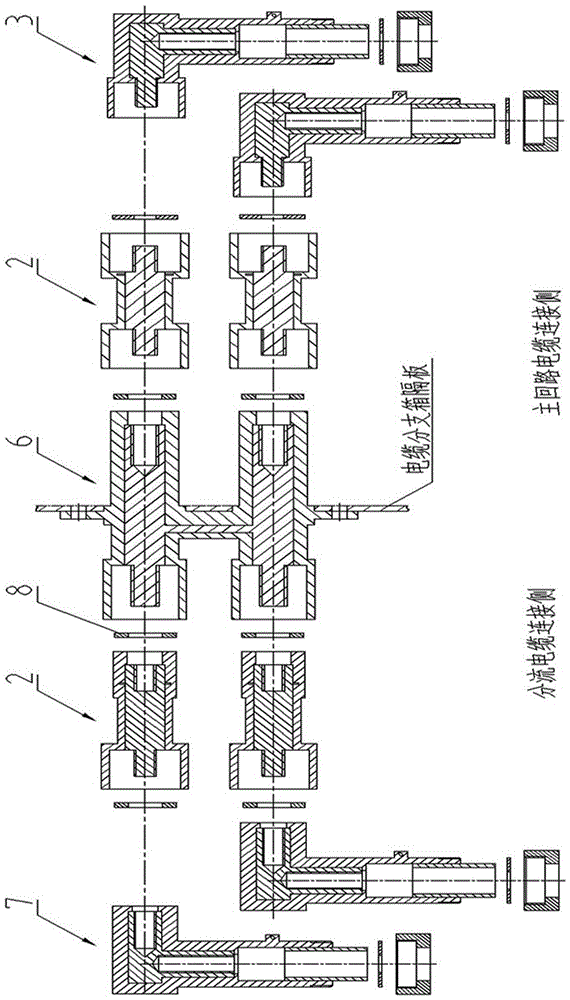

[0028] Preferred embodiment three, such as image 3 As shown, the difference between this embodiment and the preferred embodiment 1 is that: the shunt wall bushing and the butt joint are respectively type III shunt wall bushing 6 , and the L-shaped cable connection terminal also includes an internal thread hole type cable connection terminal 7 . The difference between type III shunt wall bushing 6 and type I shunt wall bushing 1 is that the main circuit cable connection side is connected with two internal thread connection ends in parallel, and the shunt cable connection side is connected with two external thread connection ends in parallel. The connection ends are coaxial with the center line, so that the type III split wall through-wall sleeve 6 forms an "I"-shaped structure. The difference between the internally threaded hole type cable connection terminal 7 and the externally threaded head type cable connection terminal is that the connection structure of the butt end is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com