A kind of automobile glass baking and bending mold

A technology of auto glass, baking and bending, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve problems such as unstable sealing, excessive glass arc profile and unsmooth, constantly changing heating elements, etc. Achieve the effects of avoiding damage, excessive smoothness of the arc profile of the automobile glass, and continuous and stable auxiliary heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

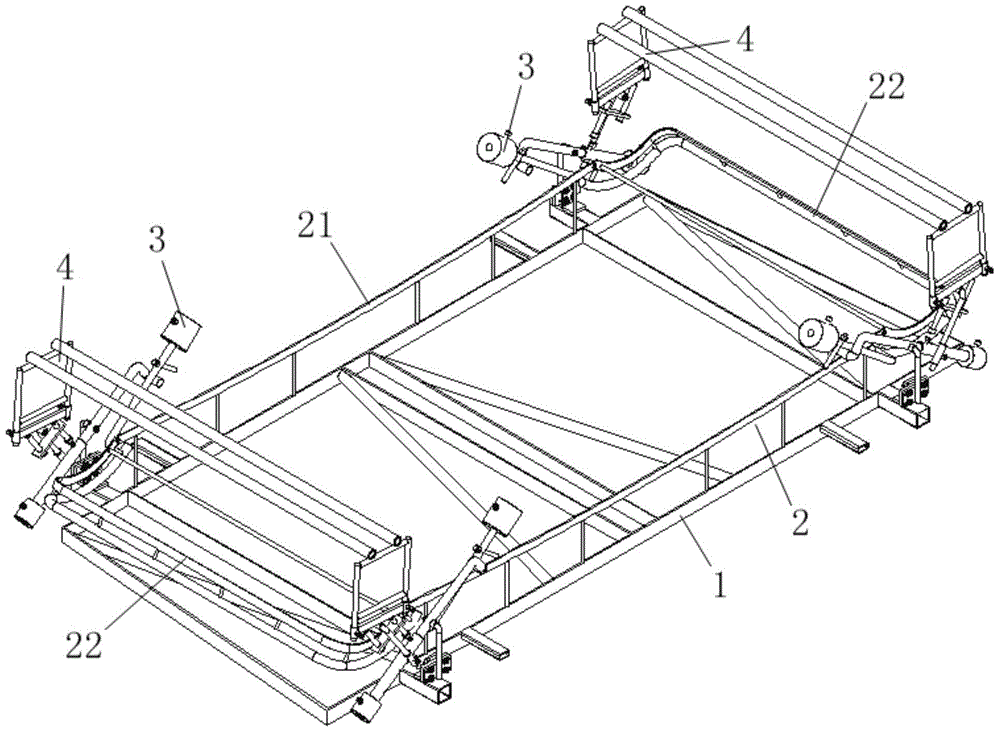

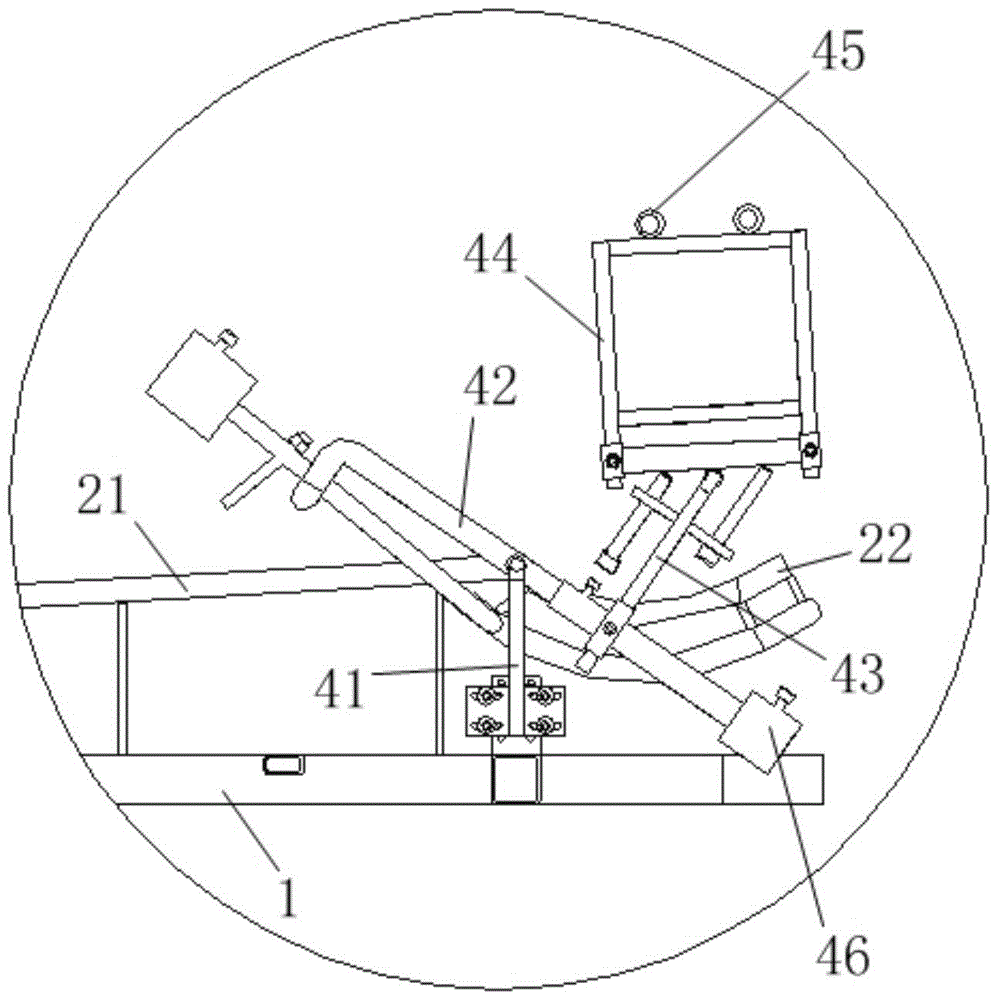

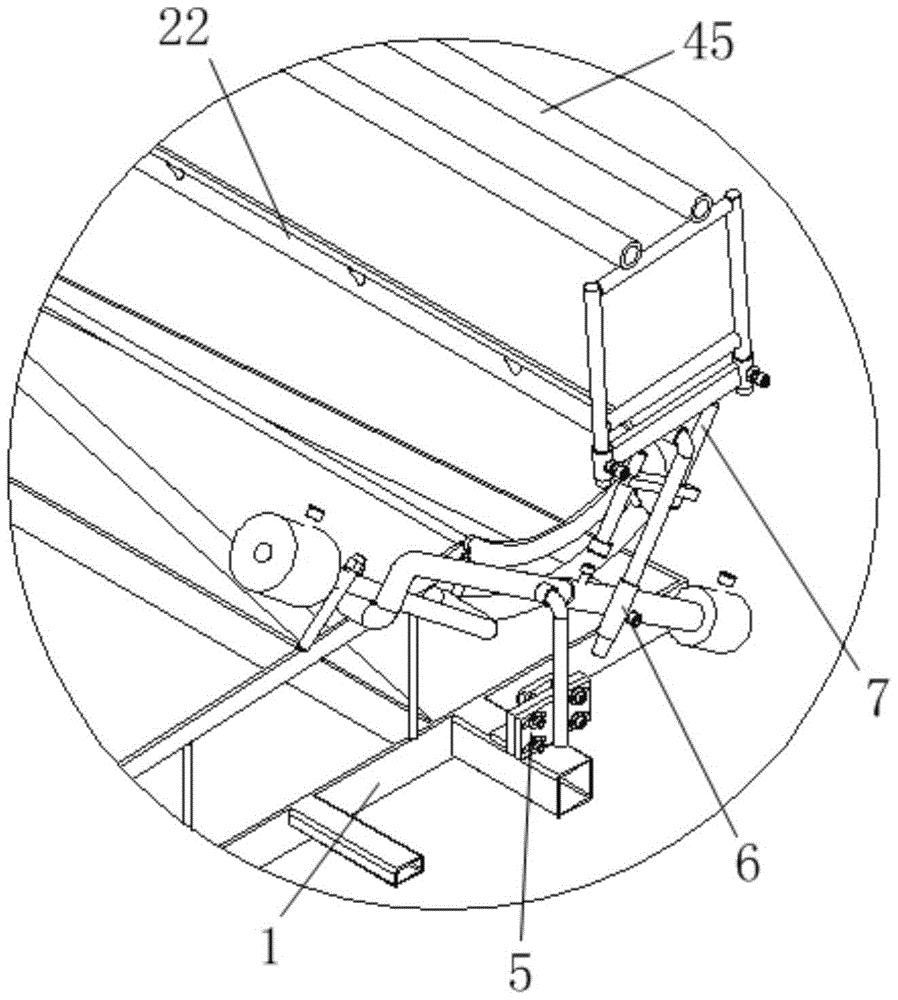

[0026] Such as figure 1 and figure 2 As shown, a kind of automobile glass baking mold according to the present invention can bake and shape automobile glass or even automobile coated glass, and it includes a base 1, a forming frame 2 and two anti-weight mechanisms 3, and the forming frame 2 includes a fixed frame 21 and two movable frames 22, the fixed frame 21 is fixed on the base 1, and the two movable frames 22 are hingedly connected with the left and right ends of the fixed frame 21 respectively, and the two movable frames 22 can rotate around their respective The hinge point rotates to form a bending profile together with the fixed frame 21. The curvature of the bending profile is equal to the curvature of the final bending shape of the automobile glass. The two anti-weight mechanisms 3 are respectively fixed with the two movable frames 22. In the process of the auto glass being gradually softened by baking and bending, the anti-weight mechanism 3 can drive the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com