Radiating type power supply device with touch sensor

A technology of contact sensor and power supply device, which is applied to parts, coupling devices, circuits, etc. of connection devices, can solve problems such as hidden safety hazards and troublesome operation, and achieve the effect of simplifying structure, saving space and saving production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below by means of specific examples and in conjunction with the accompanying drawings.

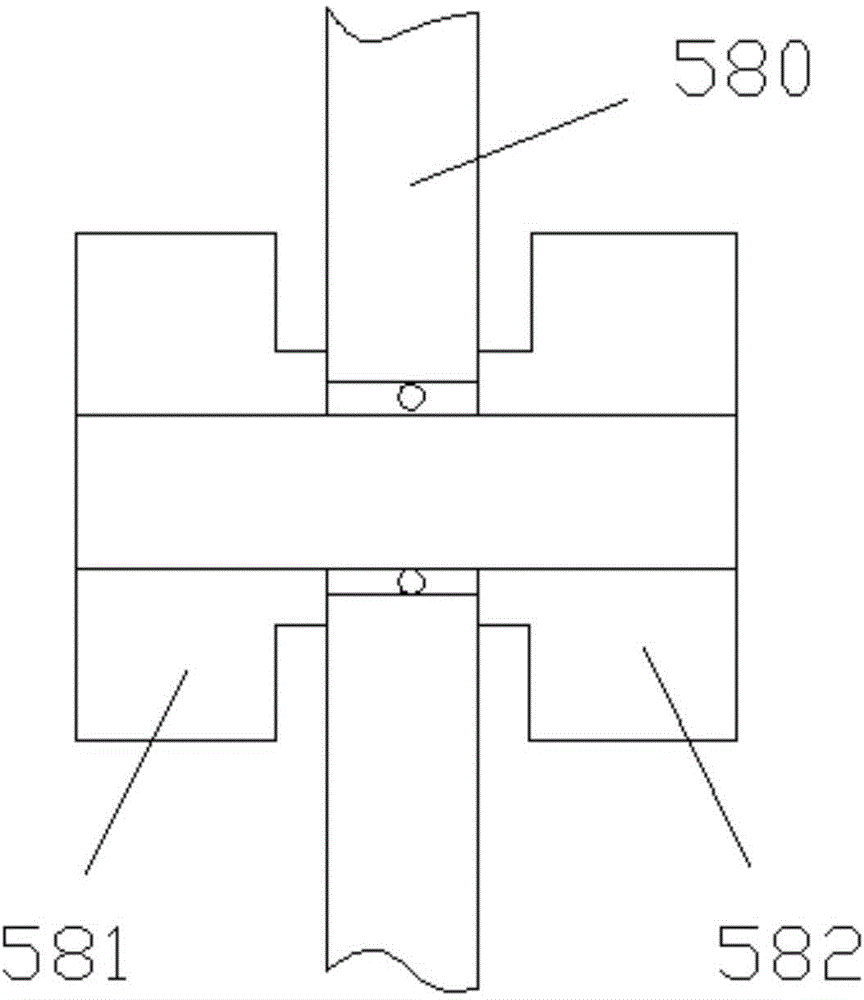

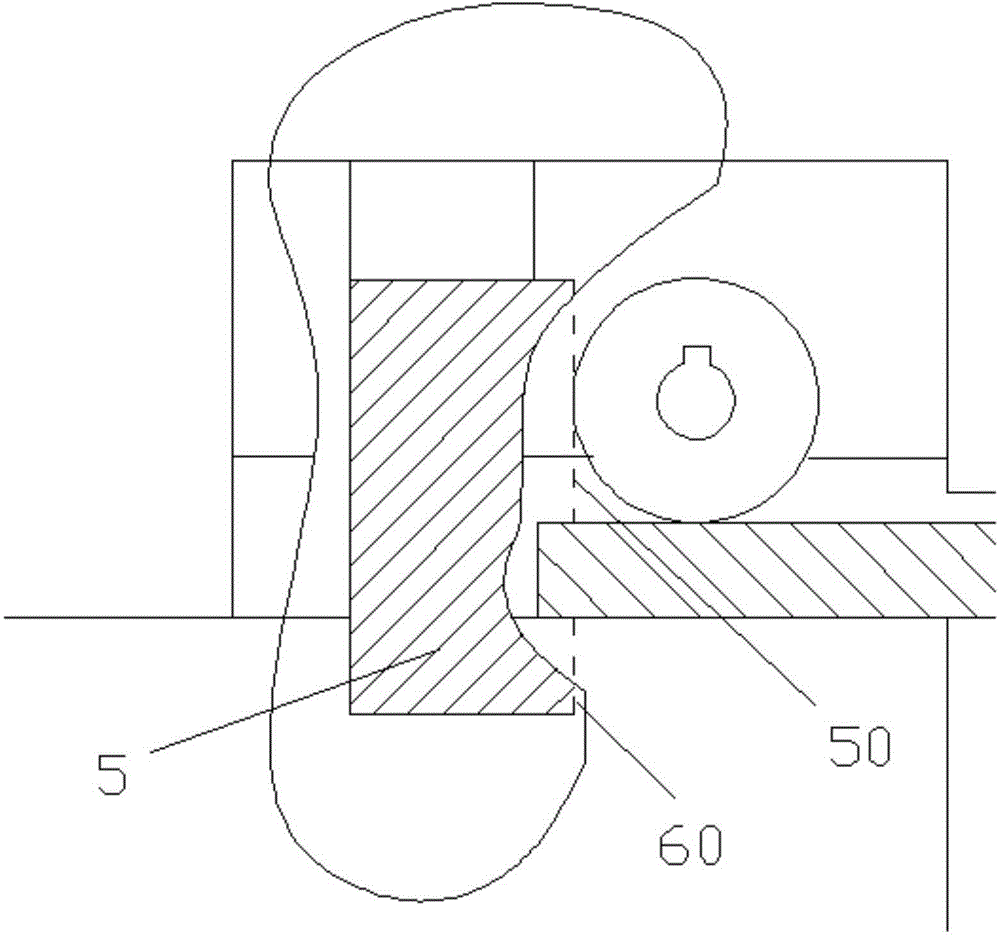

[0013] According to the embodiment, combining Figure 1-3 , a power supply device with a contact sensor and capable of dissipating heat, wherein the power supply device includes a main body 9 and a plug 6 inserted into the jack of the main body 9, and a locking and unlocking motor 91 is arranged in the main body 9 The outer surface of the locking and unlocking motor 91 is longitudinally provided with cooling fins 94 for absorbing and dissipating the heat generated by the locking and unlocking motor 91 during operation, so as to prevent the locking and unlocking motor 91 from running for a long time If the temperature is too high and burnt, the rotor of the locking and unlocking motor 91 is power-coupled with the screw 95, and the screw 95 is screwed with the screw hole in the movable part 8 in the main body 9, and the locking and unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com