Fuse unit

A fuse and plug-in technology, which is applied in the field of fuse units, can solve the problems of poor operability and the inability to adjust the direction of the fuse installation hole, etc., and achieve the effect of improving visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

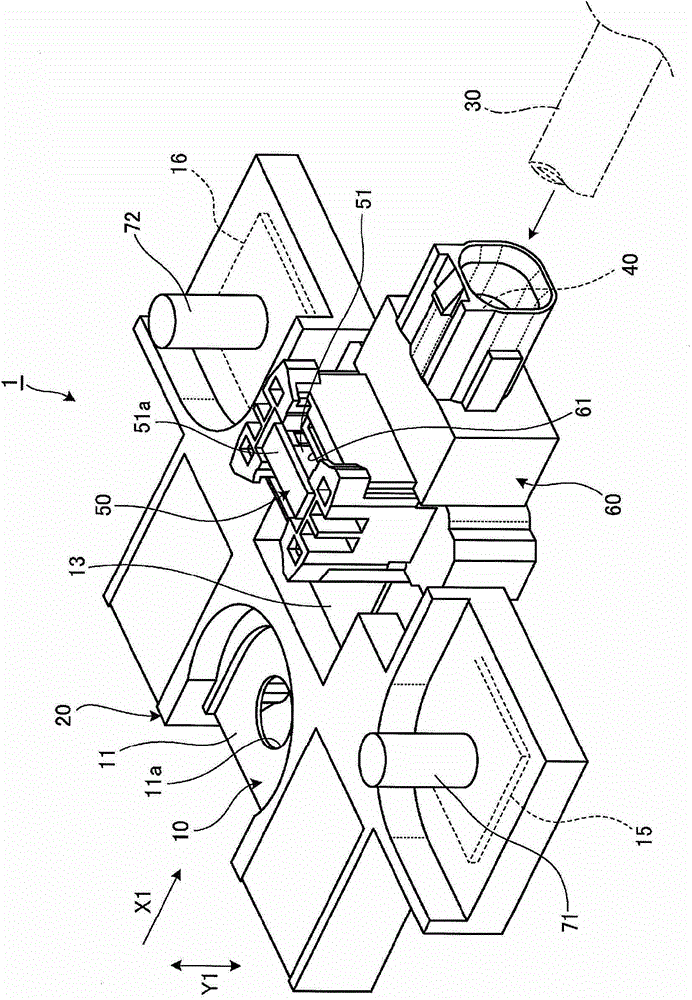

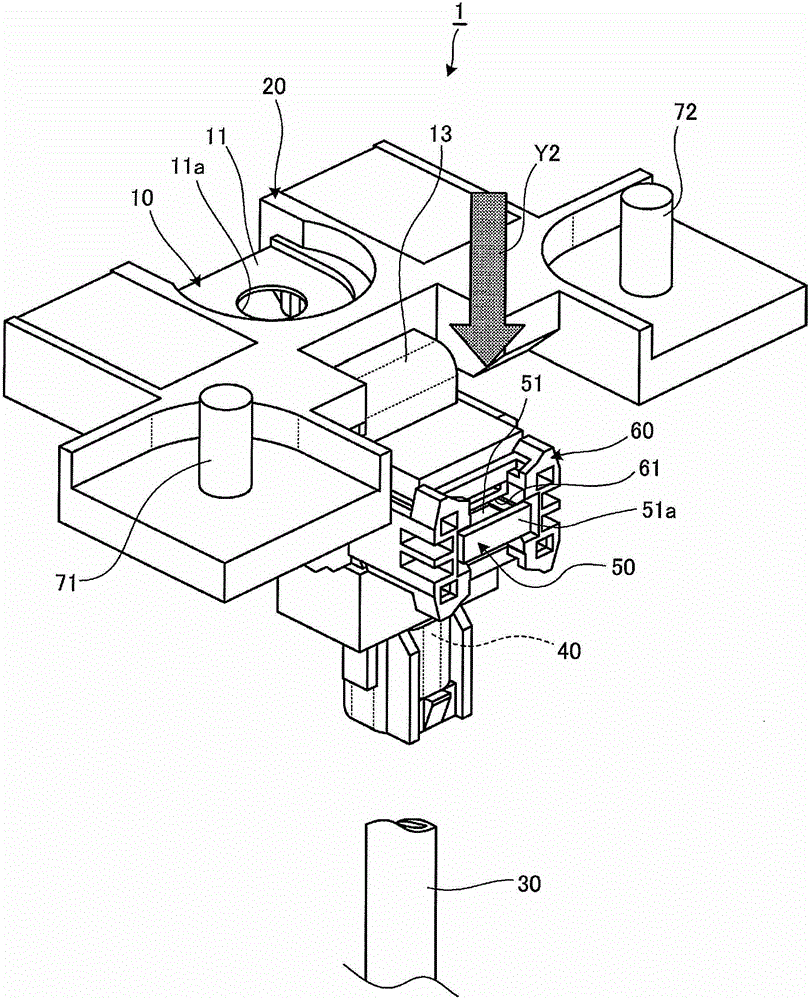

[0040] Hereinafter, preferred embodiments of the fuse unit of the present invention will be described in detail with reference to the drawings.

[0041] figure 1 is a perspective view of one embodiment of the fuse unit of the present invention, figure 2 Is to transfer the contact board part from figure 1 The shown state is a perspective view of a state where the fuse mounting hole is bent at a right angle and the orientation of the fuse mounting hole is changed by 90°.

[0042] The fuse unit 1 of this embodiment is a direct-connected fuse unit directly connected to a battery terminal (not shown) of a vehicle battery, and includes: a first terminal metal member 10 connected to a battery terminal; A housing 20 that accommodates and supports a part of the first terminal metal fitting 10; a second terminal metal fitting 40 that is connected to the wire harness 30 laid on the vehicle; and a resin-made second housing 60 that supports the first A part of the terminal metal fittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com