A ventilation structure of a hard rock cutting reducer

A reducer, hard rock technology, applied in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems affecting gear and bearing lubrication and cooling, oil leakage, reduction of reducer oil capacity, etc. The effect of improving service life, increasing oil storage, and increasing oil level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

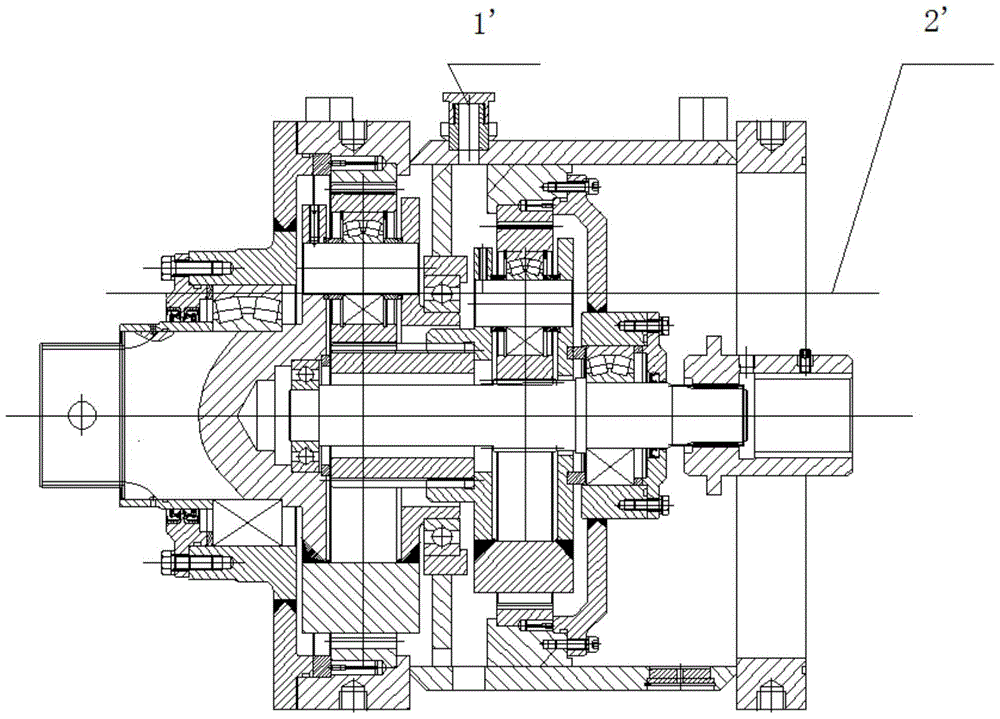

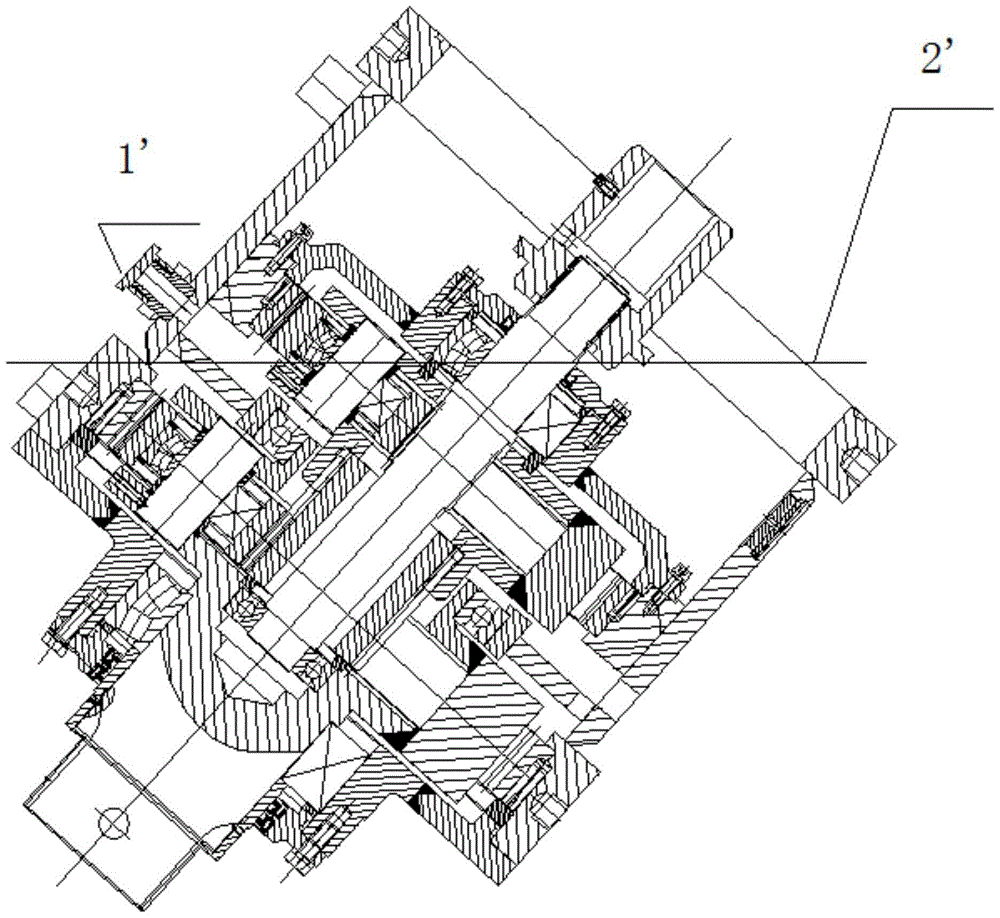

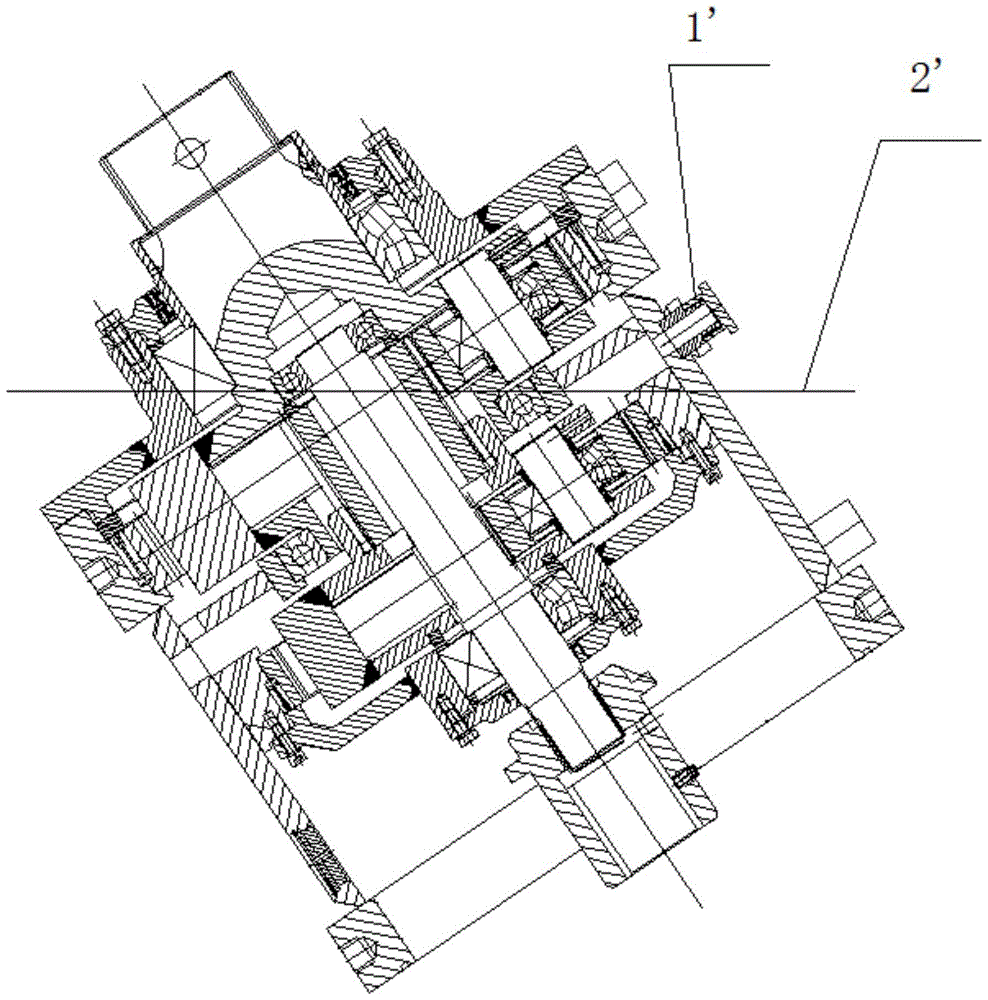

[0027] like Figure 4-Figure 7 As shown, a ventilating structure of a hard rock cutting reducer includes vent hole I1, vent hole II2, vent flow channel I3, vent flow channel II4 and vent cap 5, and the vent cap 5 is located in the housing of the reducer The middle part of the upper top 6, the vent hole I1 is located on the side of the inner wall of the upper top 6 close to the output end of the reducer, the axis of the vent hole I1 is perpendicular to the inner wall of the upper top 6, the One end of the vent hole I1 communicates with the housing of the reducer, and the other end of the vent hole I1 communicates with the vent cap 5 through the vent flow channel I3,

[0028] The vent hole II2 is located on the side of the inner wall of the upper top 6 close to the input end of the reducer, the axis of the vent hole II2 is perpendicular to the inner wall of the upper top 6, and one end of the vent hole II2 is connected to the input end of the reducer. The housing of the reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com