Composite pipe oil tank device and application method

A composite pipe and oil tank technology, which is applied in the direction of oil supply tank device, fluid pressure actuator, servo motor, etc., can solve the problems of easy damage of sealing ring, high cost, complex structure, etc., and achieve long life, low cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

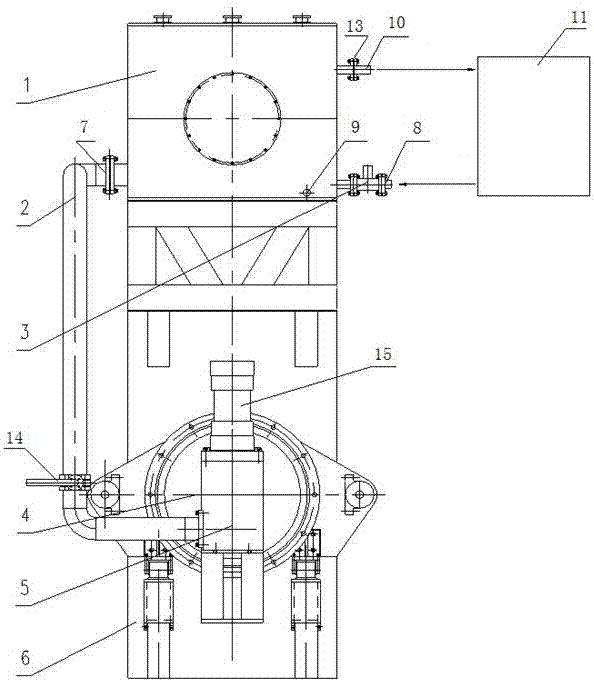

[0018] In order to solve the problem of the high cost and complex structure of the existing oil tank device on the main hydraulic cylinder used for composite pipe forming equipment or the easy damage of the sealing rings of important components such as the main hydraulic cylinder and high-pressure cut-off valve due to the oil quality of the oil tank cannot be circulated problem, this example provides figure 1 The composite pipe oil tank device shown includes a frame 6, the main hydraulic cylinder 4 is installed on the lower end of the frame 6, and the oil tank 1 is fixedly installed on the upper end of the frame 6, and the side of the oil tank 1 is provided with an oil suction port 7 and an oil discharge port 9 , the oil inlet 8 and the overflow port 10, the oil suction port 7 is connected to the oil delivery pipe 2, the oil delivery pipe 2 is connected to the inlet end of the cut-off on-off valve 5, and the outlet end of the cut-off on-off valve 5 is connected to the oil inlet...

Embodiment 2

[0026] On the basis of Embodiment 1, further, considering the effect of gravity, in order to allow the oil in the fuel tank 1 to be discharged conveniently, the overflow port 10 is opened at a position close to the top cover of the fuel tank 1, and the oil suction port 7, the exhaust port Both the oil port 9 and the oil inlet 8 are located below the overflow port 10 and close to the bottom cover of the oil tank 1 .

Embodiment 3

[0028] On the basis of Embodiment 1, the spool of the cut-off on-off valve 5 is equipped with a drive cylinder 15 that realizes the switch of the cut-off on-off valve 5, and the drive cylinder 15 replaces the valve rod to easily realize the switch on-off on-off valve 5; The diameter of the cut-off on-off valve 5 is 200mm, and the pressure is above 20MPa. The diameter of the cut-off on-off valve 5 purchased on the market is small, the flow rate is small, and the pressure is less than 20MPa, which does not meet the requirements of the composite pipe oil tank device provided by this embodiment. Requirements, therefore, a cut-off on-off valve 5 with a diameter of 200 mm is designed, the flow of the cut-off on-off valve 5 is increased by increasing the diameter, and the cut-off on-off valve 5 is under pressure above 20 MPa. In order to ensure the safety of the entire oil delivery process, the oil delivery pipe 2 is connected in series with a butterfly valve 14. When the main hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com