A device for sterilizing beverages

A sterilization device and beverage technology, which is applied in the fields of dairy products, food science, heating, etc., can solve the problems of non-renewable resources, long sterilization time, large energy consumption, etc., to improve sterilization efficiency, prolong heating time, The effect of improving the heat absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

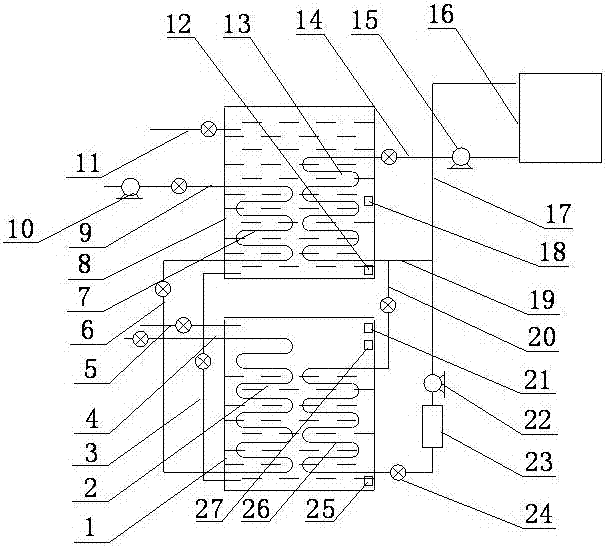

[0023] Such as figure 1 As shown, the beverage sterilizing device of the present invention includes a sterilizing mechanism, a preheating mechanism and a solar collector 16, the sterilizing mechanism is connected to the solar collector 16 through a high-temperature heat-conducting oil pipe 17, and the preheating The mechanism is connected with the solar heat collector 16 through the oil return pipe 14 .

[0024] The sterilization mechanism has a closed heat exchange container 1, and the beverage sterilization coil 2 and the heating coil 26 are arranged in the heat exchange container 1, and the oil inlet end of the heating coil 26 is connected with the high-temperature heat-conducting oil pipe 17, the oil outlet is connected to the preheating mechanism through the heat transfer oil connecting pipe 20, the liquid inlet end of the beverage sterilization coil 2 is connected to the preheating mechanism through the beverage connecting pipe 6, and the liquid outlet is connected to th...

Embodiment 2

[0031] see figure 1 The structure of the beverage sterilizing device in this embodiment is basically the same as that in Embodiment 1, the only difference being that an auxiliary heater 23 is provided on the high-temperature heat-conducting oil pipe 17 for production maintenance when there is no sun and the reserve of high-temperature heat-conducting oil is insufficient. The beverage sterilizing device is provided with a control mechanism, and the control mechanism is respectively connected with the booster pumps 2, 15, 10, the auxiliary heater 23, the pressure sensor 21, the temperature sensors 27, 18, the water level sensors 25, 12 and the The signal connection of the control valve 24 can realize the automatic control of the production process of the whole sterilization system. The beverage sterilizing coil 2, the beverage preheating coil 7, the heating coil 26 and the preheating heating coil 13 are all made of aluminum or copper, which has a high heat transfer efficiency an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap