A side fastening tool for tin bath bottom bricks

A technology for tin bath bottom bricks and fastening tools, which is applied in the field of tin bath forming equipment, and can solve problems such as threaded fasteners that cannot be fastened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

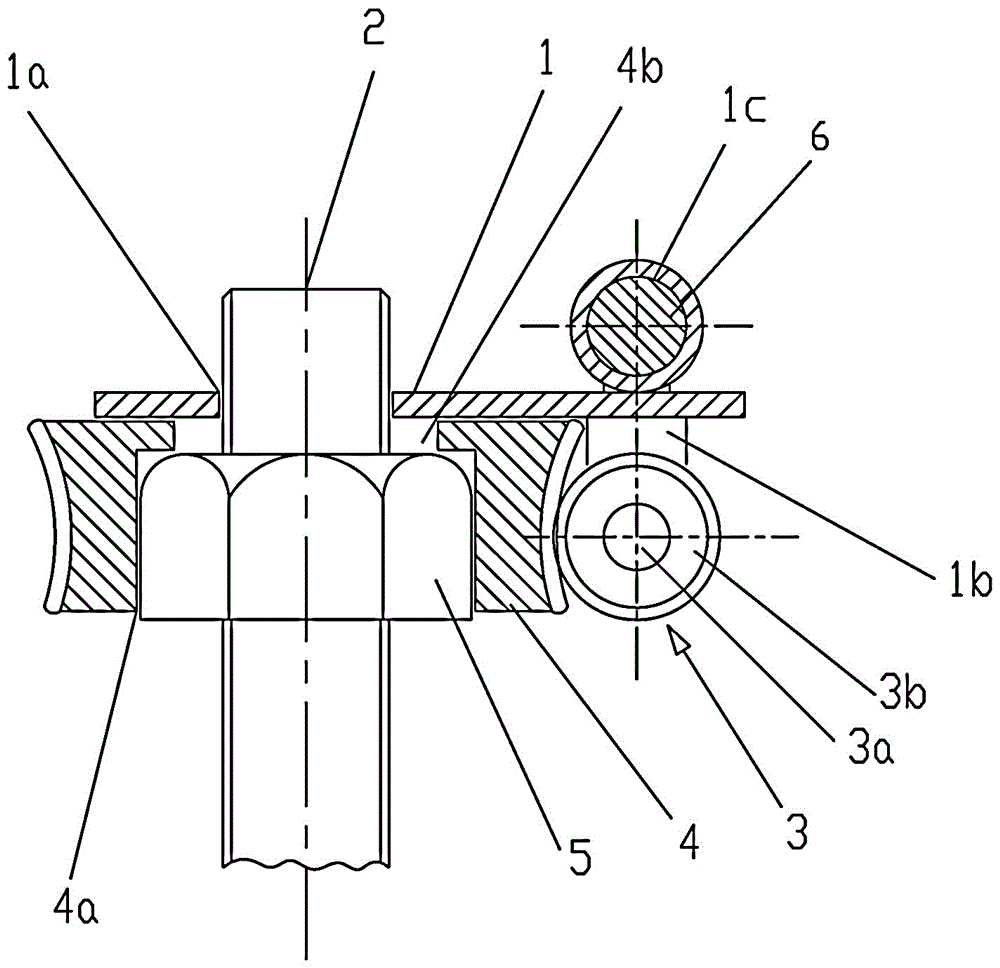

[0021] Embodiment 1 A side fastening tool for tin bath bottom brick 1

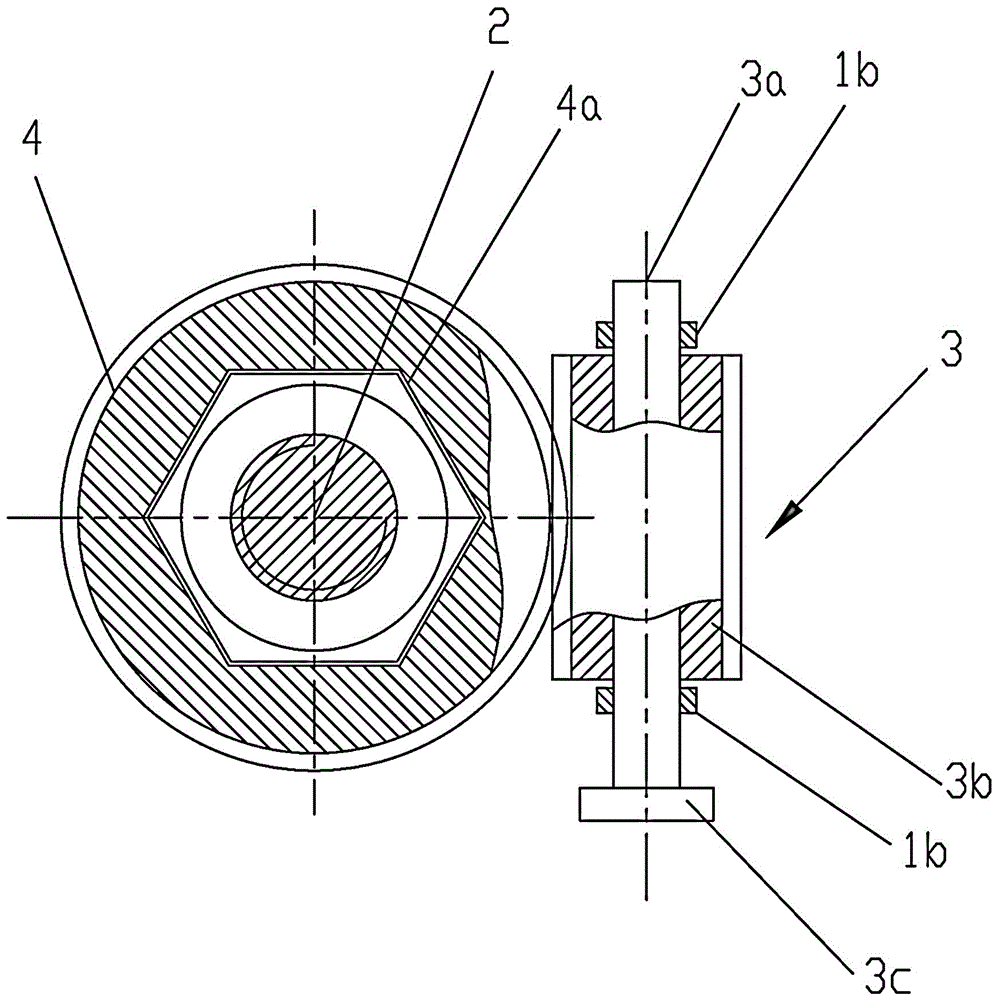

[0022] A side fastening tool for tin bath bottom tiles such as figure 1 As shown, it includes a screw 2, a nut 5 is screwed on the screw 2, and the nut 5 is covered with a worm wheel 4. The center of the worm wheel 4 is provided with a polygonal groove 4a with a regular hexagonal cross section, and the center of the bottom of the polygonal groove 4a is provided with a cylindrical screw hole 4b. The polygonal groove 4a is socketed with the nut 5, and the non-cap end of the screw 2 passes through the screw hole 4b.

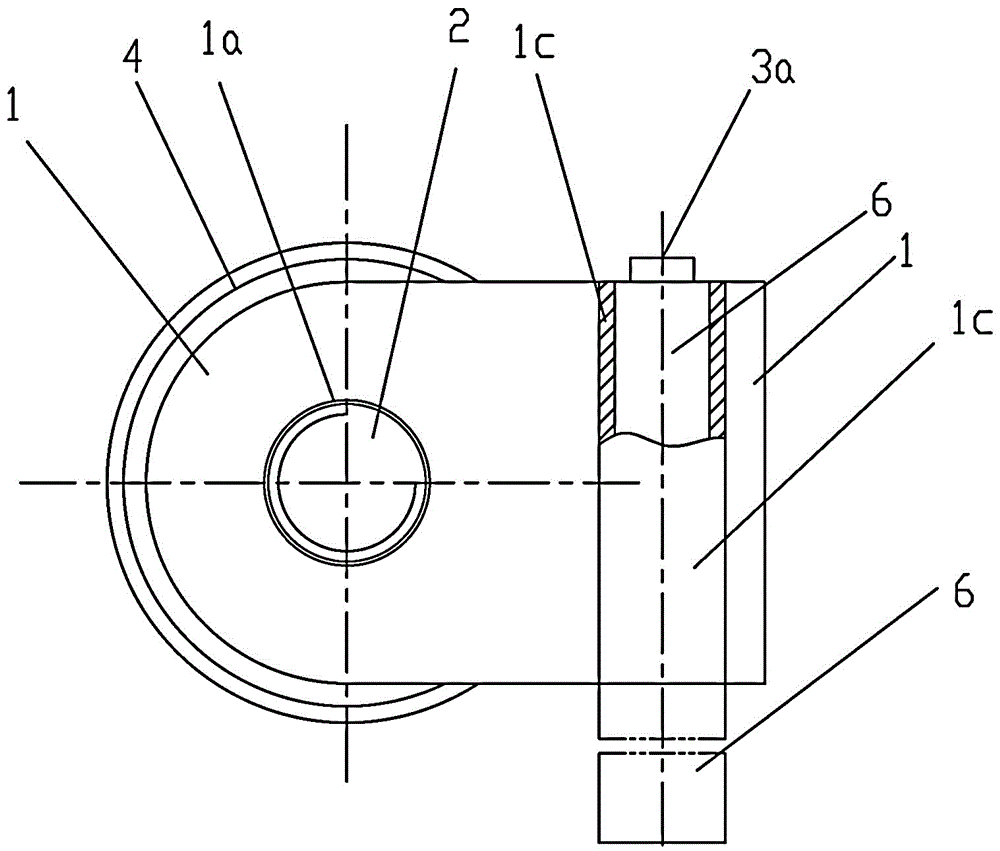

[0023] Such as figure 1 , figure 2 and image 3 As shown, the non-cap end of the screw 2 is connected to the base plate 1, one end of the base plate 1 is provided with a cylindrical fixing hole 1a whose axis is perpendicular to the plate surface, a fixing sleeve 1c is set on the other end of the base plate 1, and a pair of Hinge support 1b. The fixing hole 1a is sleeve-fitted with the end ...

Embodiment 2

[0027] Embodiment 2 A side fastening tool for tin bath bottom brick 2

[0028] A side fastening tool for tin bath bottom tiles such as Figure 4 As shown, it includes a tin bath bottom plate 8, a group of screw rods 2 are welded on the tin bath bottom plate 8, a group of refractory tin bath bottom bricks 7 are laid on the tin bath bottom plate 8, and two axes and tin bath bottom bricks 7 are arranged on each tin bath bottom brick 7. The vertical fastening hole 7a of the tank bottom plate 8, the fastening hole 7a is a blind hole communicated with the bottom surface of the tin tank bottom brick 8 at one port. The bottom brick 7 of the tin bath is provided with horizontal side tightening holes 7b which are respectively connected with the corresponding fastening holes 7a crosswise and orthogonally.

[0029] The corresponding screw rod 2 is sleeved in the fastening hole 7a, and the upper end of the screw rod 2 is connected to the following parts in the side tightening hole 7b. Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com