Grinding head fixing device of saw blade grinding machine

A technology for fixing devices and sharpening machines, which is applied to tool trimming of sawing machine devices, metal sawing equipment, and metal processing equipment. It can solve the problems that manual sharpening cannot meet production development, high labor intensity, and poor results The effect of light weight, fast adjustment speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

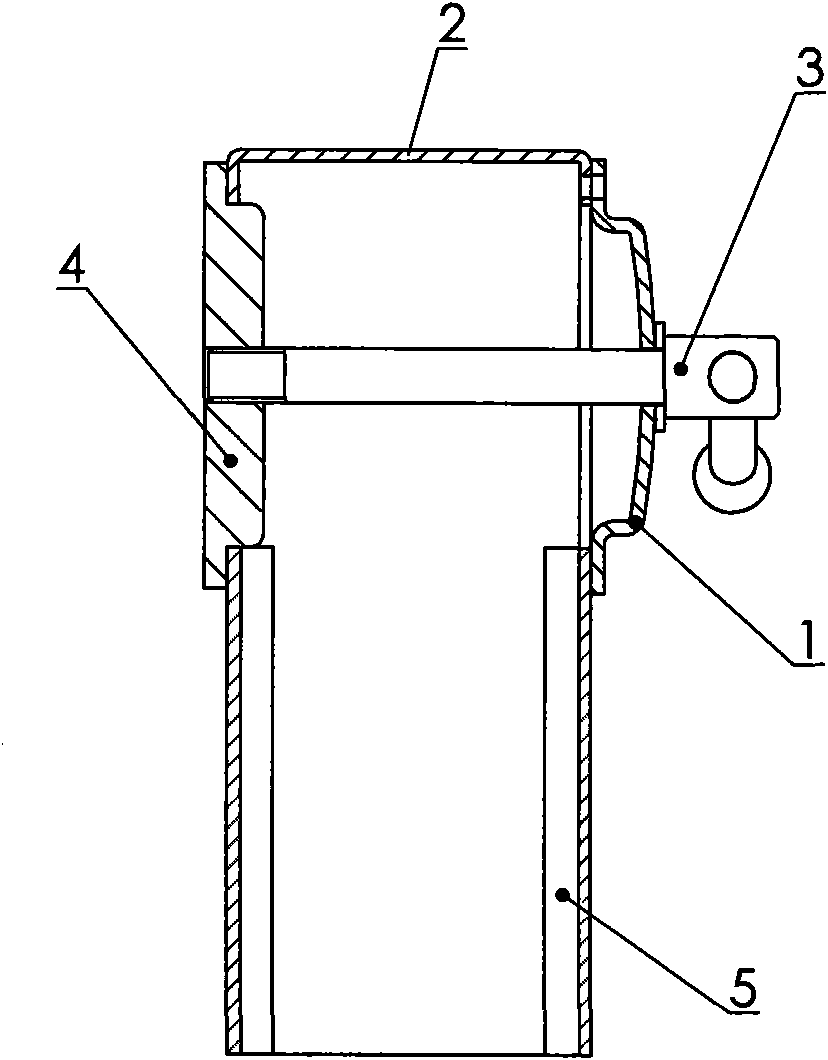

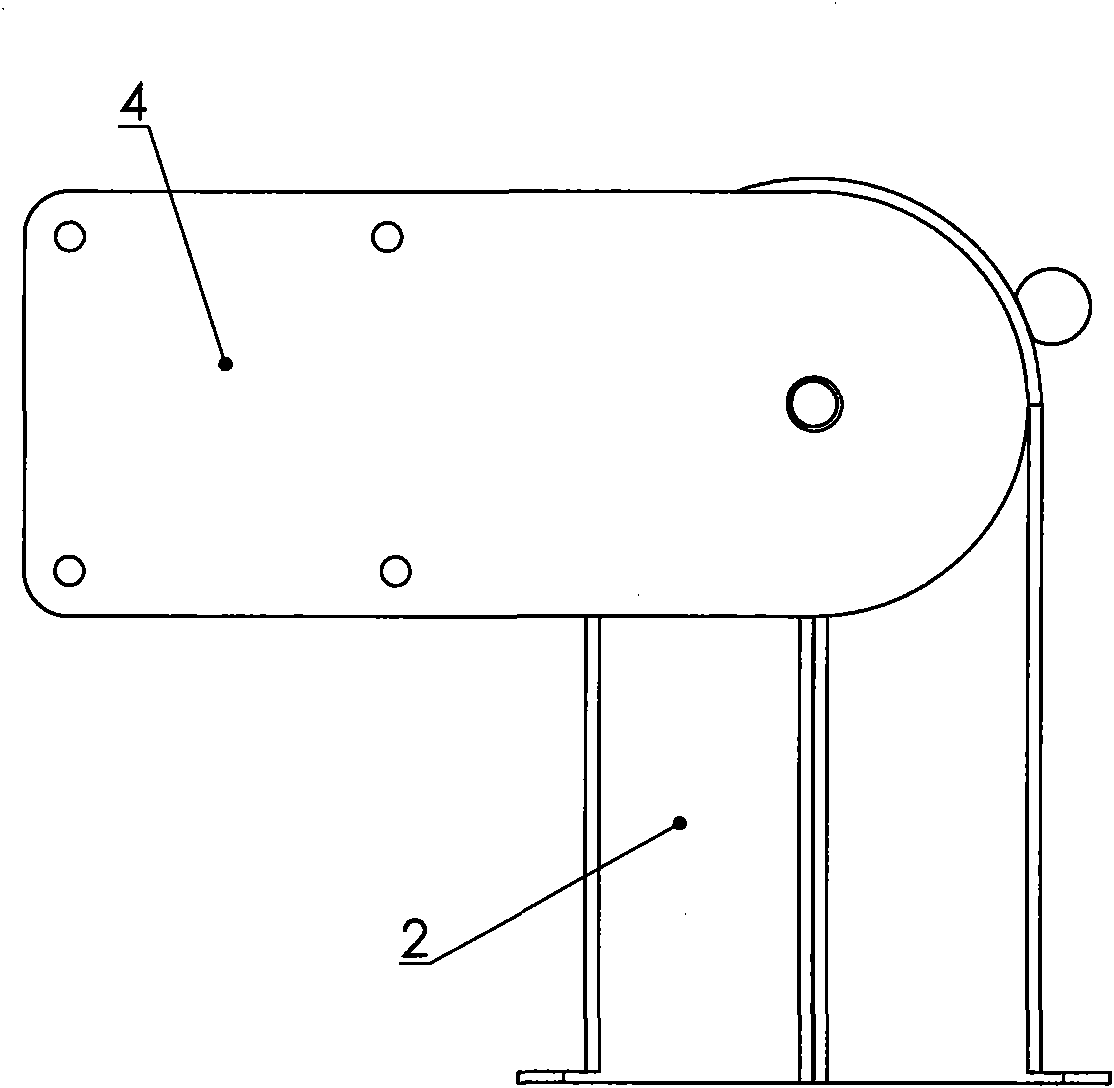

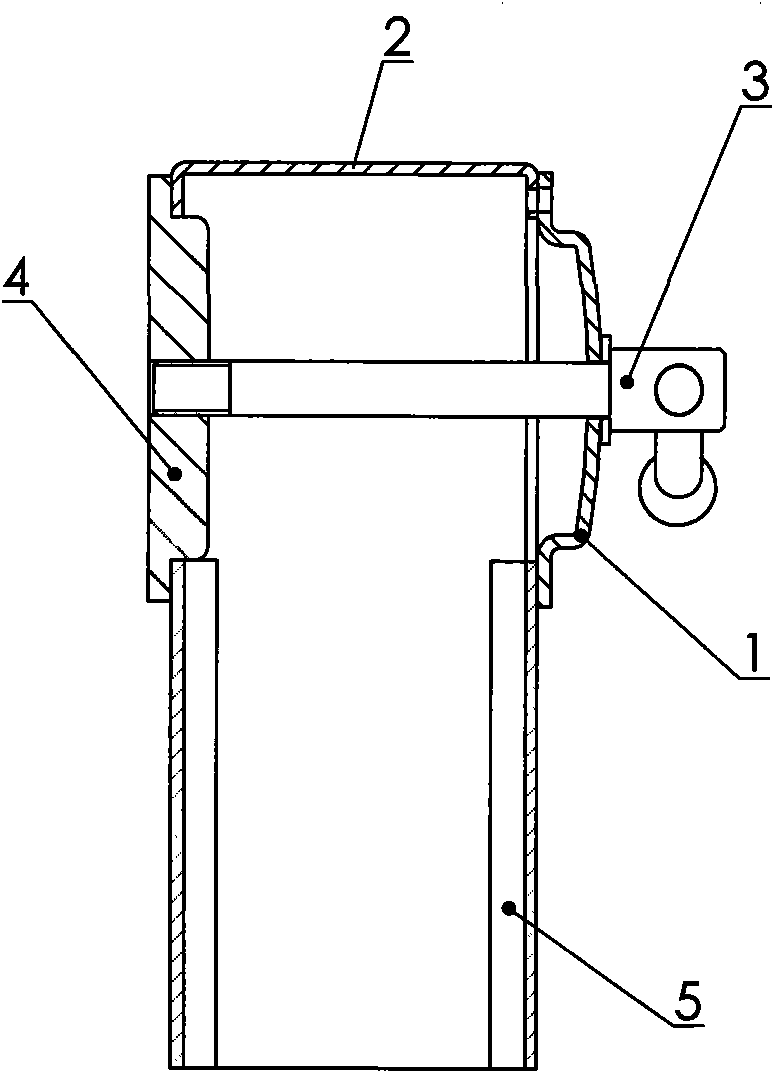

[0012] The most advantageous embodiment of the present invention is: the box body 2 is formed by pressing a steel plate, the lower part is provided with a flange 5 for welding, the upper part is semicircular, and a through hole is provided at the semicircular part, and the through hole at the inner end is provided with a motor seat 4 , the through hole at the outer end is provided with an end cover 1, a small hole is provided on the end cover, a boss slightly smaller than the through hole is provided on the motor seat, a screw hole is provided in the middle of the boss, and the locking handle 3 passes through the end The cover hole is connected with the screw hole of the boss.

[0013] A motor is installed on the motor base 4 of the present invention, which is collectively called a grinding head device together with emery wheels.

[0014] The invention has the advantages of simple and reasonable structure, material saving, light weight, low cost, reliable locking, fast adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com